3

SAVETHESEINSTRUCTIONS

16”PowerHeadMaintenanceInstructions

WARNING!Donotattemptmaintenanceorrepairsbeforedisconnectingcordfromelectricalpower

source.

MAINTENANCE

Lubrication–Themotorhassealedbearingswhich

requirenofurtherlubrication.Castersandwheels

shouldbeoiledasrequired.

Current–Machineshouldberunonlyonvoltage

specifiedonnameplate.

Hose–shouldberemovedfrommachineaftereach

use.Thetubehandleshouldberemovedfromhose.

Itshouldthenbelaidinaloosecoilorhungover

severalpegsonthewalltoremovethestrainonit.

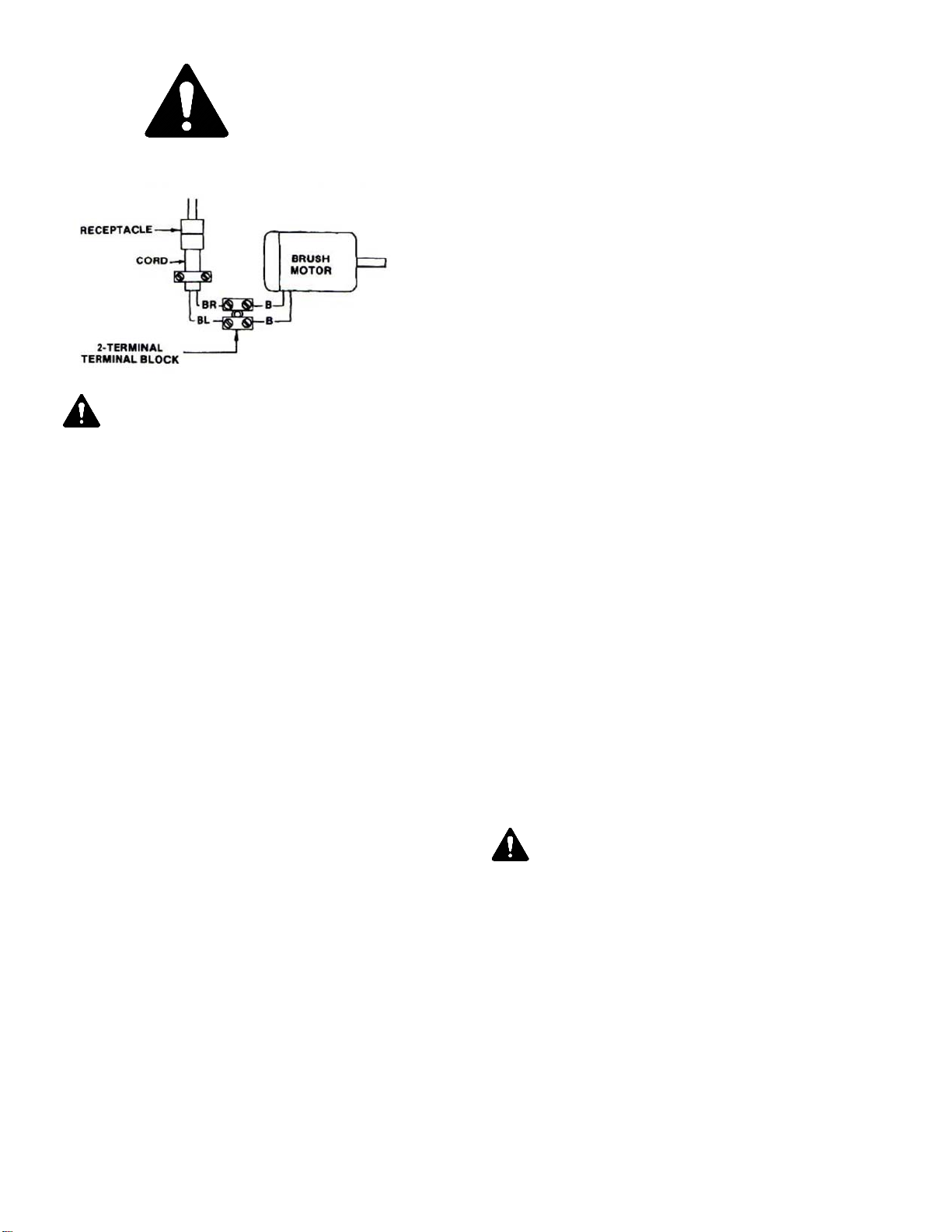

Cord

a) Unplugpowerheadfromthevacuumsource.

b) WithPhillipsheadscrewdriver,remove4screws

holding#25bottomplasticcoverintoposition.

c) Removetwoscrewsholdingstrainreliefinto

positionwithsmallflatbladescrewdriverwith

bladeabout1/8”wide

d) Remove2‐wireconnectionsfromterminalblock.

Notecolorandplacementofwiresremovedfor

re‐installation.

e) Re‐installstrainreliefonnewcordandinsert

wiresintoterminalblockandtighten.

f) Movestrainreliefintopositionandre‐assemble

clampontothestrainrelief.

g) Re‐install4screws.Donotovertightenscrews

intobrassinserts.

h) Pluginbrushpowerleadtovacuumsourceand

testmachine.

WHATTODOINCASEOFLOSSOFSUCTION–

Ordinarilylossofsuctioniscausedbyasimply

createdcause.Thefollowingsuggestionsare

listedasaguide.

a. Checktool,hose,andtubehandleforplugging.If

plugged,unplug.

b. Removehosefrommachineandchecksuctionat

intake,ifstillsuctionloss;

c. Checkallgasketstoseeifmakingproperseal.If

worn,replace.

d. Checkfilterbagofvacuumsourceforclogging.If

dirty,clean.

After500hoursofrunningtime,checkvacuum

motorcarbonbrushwear.Whencarbonbrushes

andcopperoncommutatorareworn,returnto

authorizedNSSservicestationforrepair.

Belt&Brush

a) Unplugpowerheadfromthevacuumsource.

b) WithPhillipsheadscrewdriver,remove4screws

holding#25bottomplasticcoverintoposition.

c) Pulloutbrushontheoppositeendofbeltuntil

brush,bearing,andbearingblockareremoved

frombrushhousing.Pullbrushandremaining

bearinguntilbrushpullsfreefrommachine.

Removestringsandhairfrombrushandbearing

shaft.Replacebrushandbearings,ifnecessary;

seebrushwear(e).

d) Removeoldbeltandinstallnewbelt(ornew

brush/bearings)overbrushmotorshaft.Pullbelt

sidebearingblockandbearingonbrushshaft

makingsurethatbearingblocksarepointedinthe

rightdirection.

(Bearingblocksaremarkedonthesidewith1or

2.)#2setdownwithheadinoperatingpositionin

thelowestextensionofbristles.#1setdown

extendsthebristleanadditional1/16”.(Make

surebotharethesameposition.)

e) BrushWear–Ifbrushbristlefailstoagitatecarpet

becauseofbristlewear,followstepsathrue.

Turnbearingblockswith#2attheupposition

whenbrushheadisinoperatingposition.

f) Runbeltaroundpulleyonbrush,stretchbeltand

insertbrushbearingintobearingblock,beltside.

g) Lineupbearingblockandbearingonshafton

oppositeendofbelt.Pushbothsidesdowninto

brushhousingmakingsurethatbearingblocksare

allthewayintoposition.Turnbrushafewtimes

tomakesurethatbeltisrunningfree.

h) Makesureshoesealisinplace.Makesureshoe

locksareinplaceonbrushhead,otherwiseshoe

willbowandvacuumingwillbeuneven.

i) Re‐install4screws.Donotovertightenscrews

intobrassinserts.

j) Pluginbrushpowerleadtovacuumsourceand

testmachine.