INSTRUCTION MANUAL FOR ARC WELDING MACHINE

IMPORTANT

Before using this device all people authorised to its use, repair

or inspection, should read the book "Safety rules for using

machines" and the "Instruction manual" specific for every

machine. Contact your distributor if you have not understood

some instructions.

It is also essential to pay special attention to the "SAFETY

RULES" Manual. The symbols next to certain paragraphs

indicate points requiring extra attention, practical advice or

simple information.

This MANUAL and the "SAFETY RULES" MANUAL must be

stored carefully in a place familiar to everyone involved in

using the machine. They must be consulted whenever doubts

arise and be kept for the entire lifespan of the machine; they

will also be used for ordering replacement parts.

IN CASE OF MALFUNCTIONS, REQUEST ASSISTANCE

FROM QUALIFIED PERSONNEL.

1 GENERAL DESCRIPTIONS

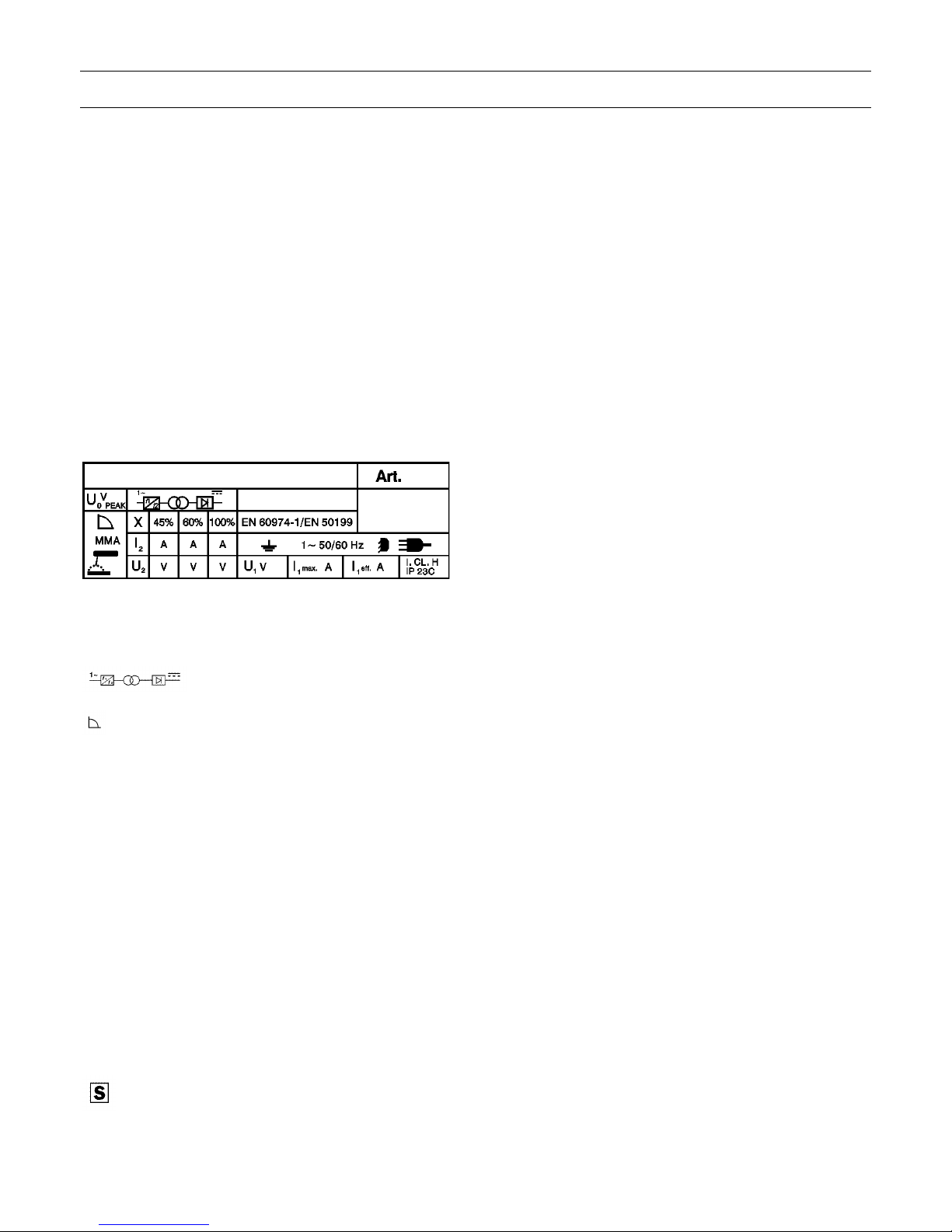

1.1 EXPLANATION OF TECHNICAL SPECIFICATIONS

EN 60974 - 1 The welder is manufactured ac-

EN 50199 cording to this international standards

Art............................ Item number that must be stated for

any demands relating to the welding

machine.

.... Single-phase static frequency con-

verter - transformer - rectifier.

.......................... Dropping characteristic.

MMA....................…. Suitable for manual welding with coated

electrodes.

Uo............................. Secondary no - load voltage.

X.............................. Duty – cycle percentage.

The duty-cycle expresses the per-centage, calculated on 10

minutes, in which the welding machine

can operate at a determined current,

without over-heating.

I2.............................. Welding current.

U2............................. Secondary voltage with I2 welding

current.

U1............................. Nominal supply voltage.

1 ~ 50/60Hz............. Single - phase supply 50 or 60 Hz.

I1max. …………….. This is the maximum value of the

absorbed current

I1eff........................ This is the maximum value of the actual

current absorbed, considering the duty

cycle.

IP23C....................... Grade of protection of frame. Grade 3

as a second number means that this

unit is fit to work outside under the rain.

......................... Symbol meaning that the welding

machine can be used in high electric

shock risk-working areas.

NOTES:..................... In addition, the welding machine has

been designed to work in areas with

grade 3 of pollution.(See IEC 664).

1.2 SPECIFICATIONS

This welding machine is a constant direct current generator,

created by the INVERTER technology, designed for welding

with coated electrodes and with the TIG procedure.

For any requests of information, please always state the item

and the serial number of the welding machine.

1.3 BEFORE CONNECTING THE WELDING MACHINE

Before connecting and switching on the unit follow all safety

rules and instructions as indicated in this manual. Make sure

that the airflow on cooling slots is not obstructed and then

proceed as follows:

1) unpack the machine

2) take care that the unit is not placed against a wall or in a

position that might cut off the air; moreover, do not cover

the unit's source with plastic materials, metal or paper

sheets because they cause the decrease of the airflow,

3) make sure that the air temperature does not exceed +40°C,

4) do not place any filtering device over the intake air

passages of this welding machine.

Warranty is void if any type of filtering device is used.

2 INSTALLATION

2.1 CONNECTION TO MAINS SUPPLY

Before connecting the unit to the mains make sure that supply

voltage corresponds to the voltage indicated on the welding

machine technical specification tag.

2.2 PROTECTION SYSTEM

The unit is equipped with internal protections, which assure a

lasting proper operation.

These protective systems are the following:

2.2.1 Electrode anti-sticking protection

When the electrode sticks itself on the piece, the machine

brings the I2current to not dangerous values for the electrode.

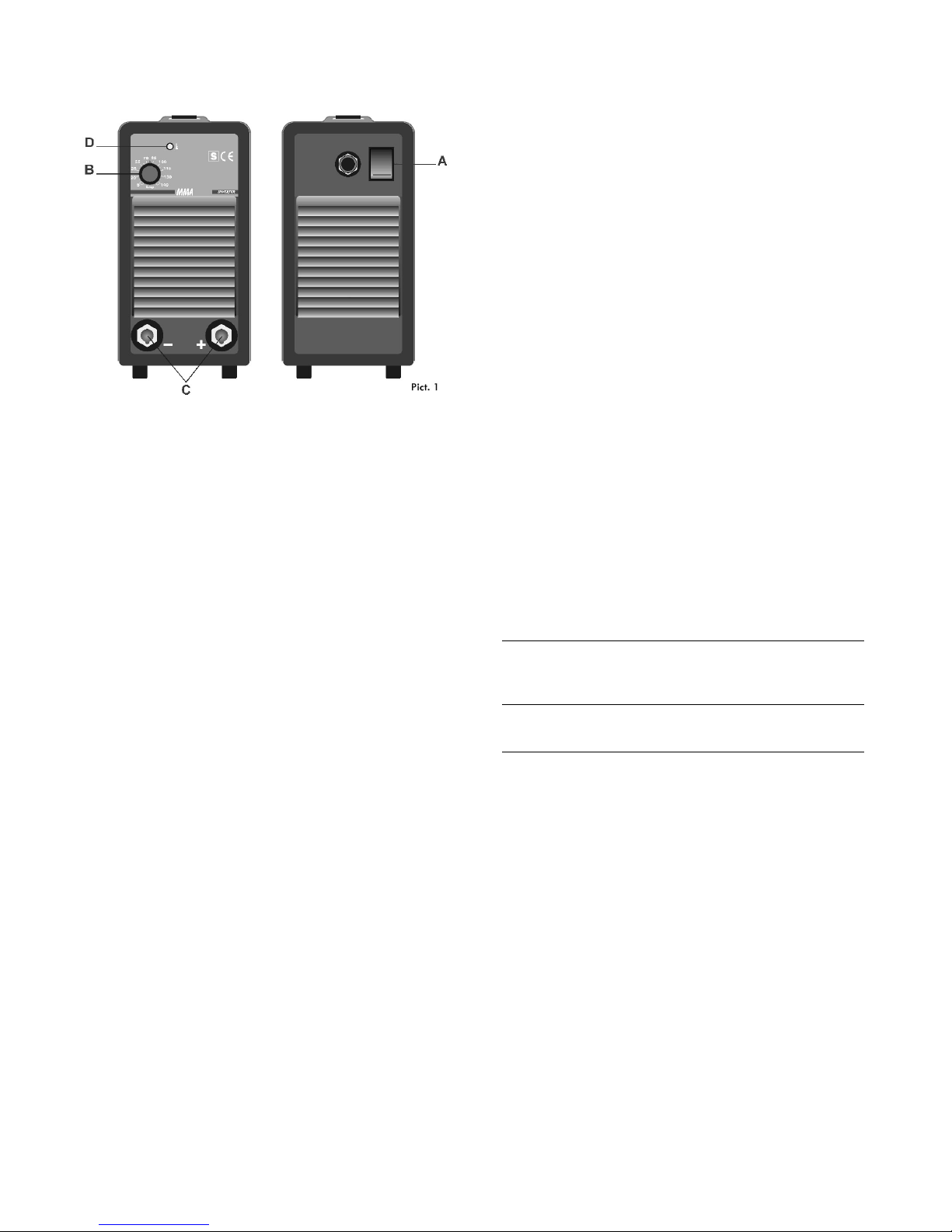

The signal light D (picture 1) indicates this operation.

2.2.2 Thermal protections

The signal light D (picture 1) indicates the intervention of this

protection. As soon as the unit has cooled down, it will be in

working conditions again.

OVER VOLTAGE CAN DAMAGE THE UNIT

2.2.3 Protection against incorrect supply voltages

If the voltage is greater than 270V when the switch (A pict. 1)

is turned on, the yellow led (D pict. 1) will flash briefly twice,

with a brief pause between flashes, and the machine will not

deliver current.

In this situation the electric circuits are protected, but the fan

may burn out after a few minutes.

In the voltage low during welding, the yellow led (D pict. 1)

flashes every 0.5 seconds and the machine does not deliver

current.

2.2.4 Motor-driven generators

These must have a power equal to or greater than 6kVA, and

must not deliver a voltage greater than 260V.