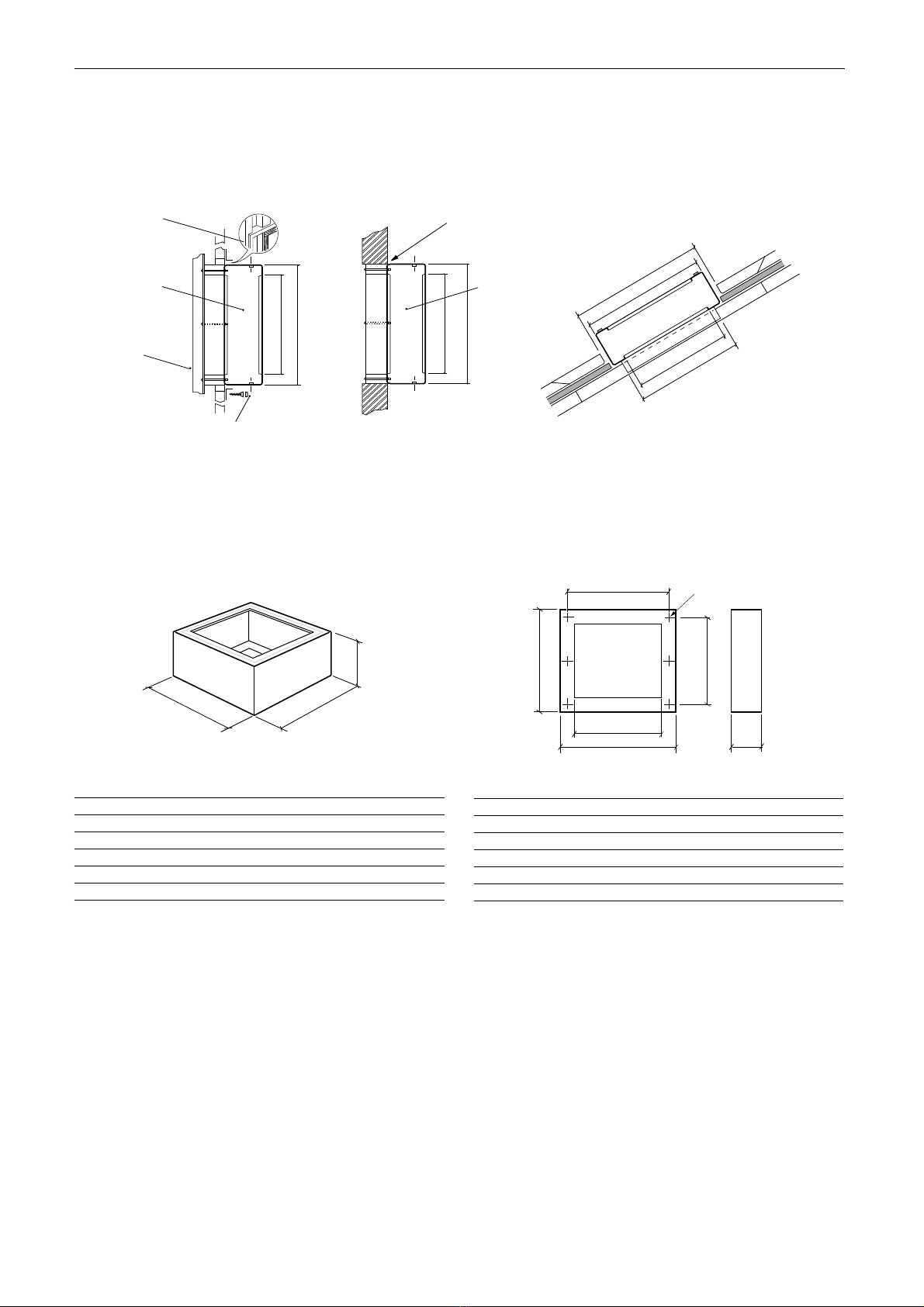

Unit MUST be installed using the appropriate wall

mounting plate (see Fig. 4b) and with the longer cowl

dimension running horizontally.

On inclined roofs, the longer dimension of the cowl must be

running ACROSS roof slope. Unit can be installed at an angle

of up to 80Ofrom the horizontal with the cowl so aligned.

Introduction

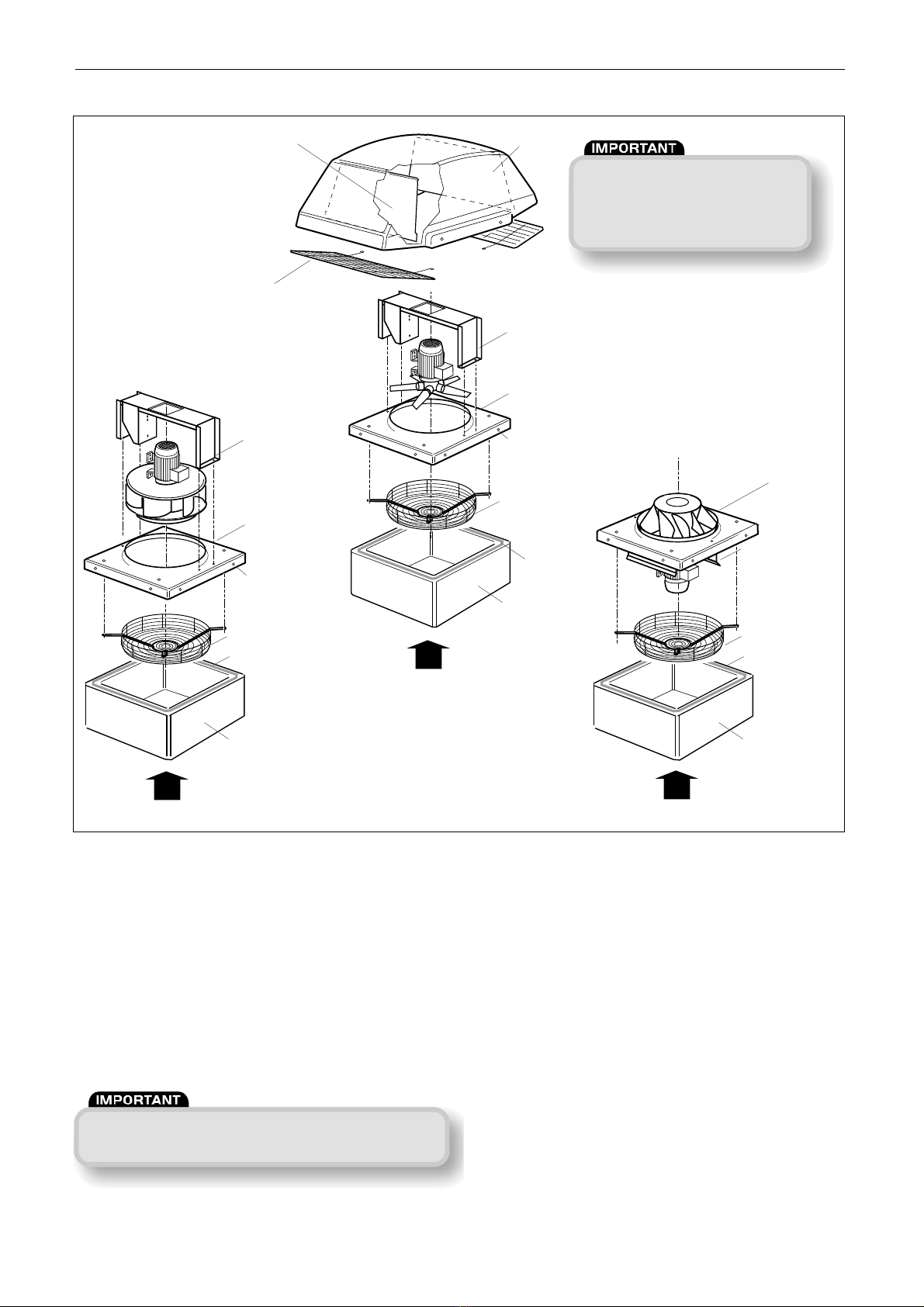

The units are manufactured using a range of six basic cowl

sizes A - F. Impellers are available in axial, mixed flow or

centrifugal versions.

Coding:

TRA = Axial Flow, TRM = Mixed Flow, TRC = Centrifugal

A given cowl size may serve more than one size impeller.

e.g. TRA500 & TRA560 use a size C cowl. (Table on page 2).

Each unit consists of a base incorporating a spun venturi plate,

a bridge* from which the motor and impeller are suspended and

a GRP cowl (fig. 1).

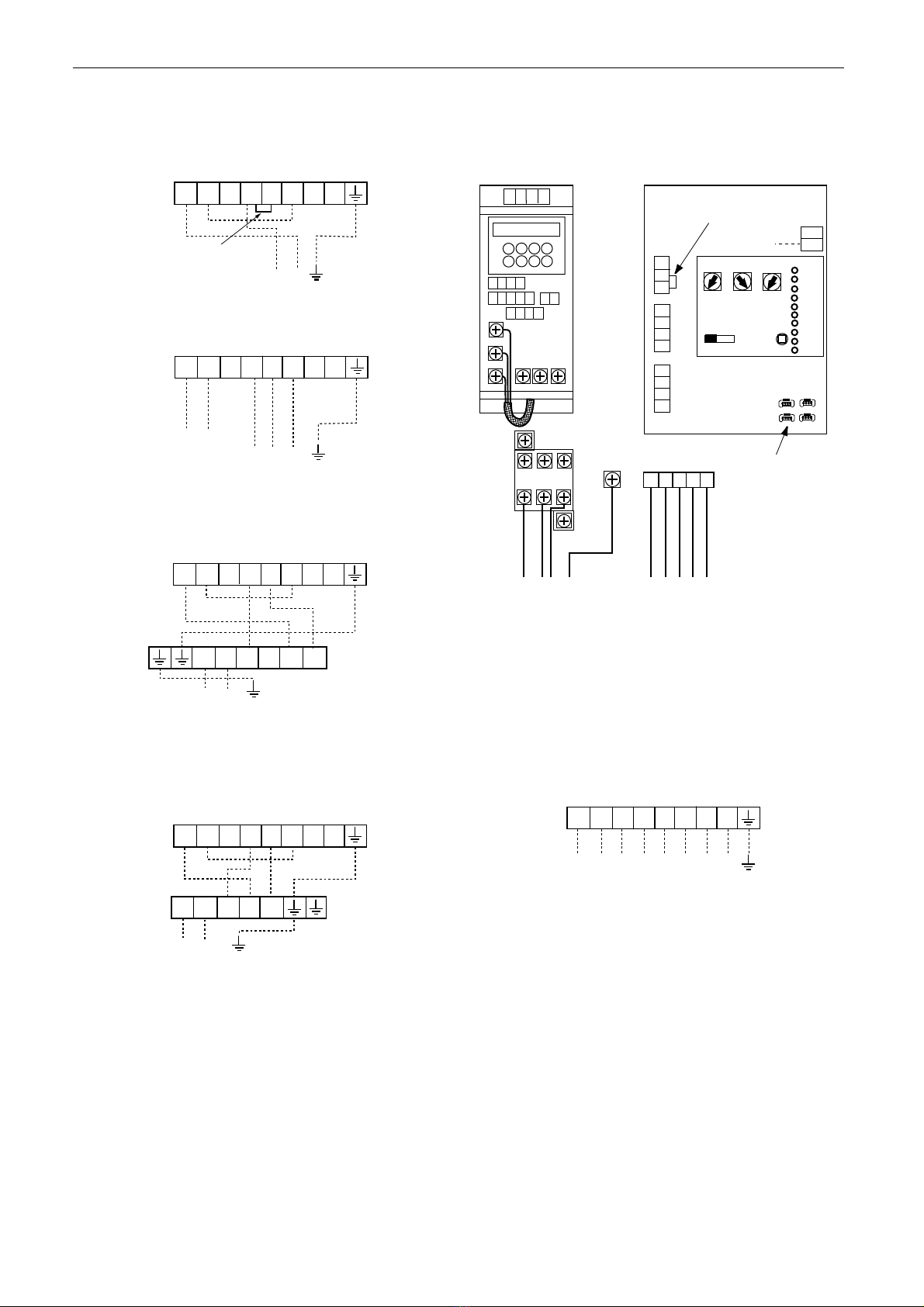

Motors are manufactured to BS5000, have sealed for life

bearings and have integral thermal protection which must be

incorporated into the control wiring. Failure to use this device

will invalidate the equipment warranty.

1.0 Handling

Units must at all times be handled carefully to avoid damage or

distortion. The unit is delivered fully assembled and mounted

on a pallet for ease of handling. When lifting or hoisting units,

care must be taken to ensure that no pressure is applied to the

cowl. Lifting eyes, suitable for all units, are available.

Purlin Box / Curb

Purlin box / curbs are manufactured in galvanised mild steel.

The upper face of the purlin box is fitted with a sealing strip.

When installed, the curb must be securely attached to the

trimmer angles.

Soaker Sheet

Soaker Sheets can be supplied by Nuaire. Manufactured in high

quality GRP, each sheet is 19500 mm long and can be supplied

to match most roof profiles. The soaker sheets are designed to

be used over a prefabricated curb.

2.0 Installation

The installation must be carried out by competent personnel in

accordance with the appropriate authority and conforming to all

statutory and governing regulations.

The unit is delivered completely assembled and a protective skin

prevents damage to the unit. It is strongly recommended that

this protective skin is allowed to remain in position for as long

as possible. When neccessary, the skin should be removed

using a sharp knife, taking care not to score the unit surface.

The unit can now be inspected for damage. Any accumulation of

dirt should be removed (see cleaning, page 6).

The unit is designed for roof mounting but can be wall mounted

using the optional wallkit available from Nuaire (see page 3).

2.1 Roof installation

Check that the curb mounting surface is flat and that the seal-

ing strip is in position. (A suitable mastic may be used as an

alternative).

If backdraught shutters or inlet side guards are to be fitted they

should be installed centrally in the curb.

Curbs other than Nuaire purlin box/curbs should be fitted with

timber capping. On timber capped curbs the units may be

attached using coachbolts or similar. When attaching to Nuaire

purlin box/curbs the use of TEK self drilling screws (type SF

46516) or self tapping screws is recommended.

Holes are provided in the skirt of the units base/venturi plate.

(See fig. 5).

2.2 Wall installation

If still assembled, separate the unit and wall plate by removing

the screws and washers from around the unit skirt. Retain the

fixings. Depending on the type of wall, prepare a hole to the

dimensions shown on page 3. For a solid wall, fit the hole with

a timber frame as shown. Drill and fit appropriate wall plugs

and secure the timber frame. On completion, the frame must

be flush with the outside surface of the wall.

For installation to a profile sheet wall, fit a suitable timber

frame supported by means of angle-iron sections. The timber

frame should, on completion, be flush with the outside sheet

profile (Fig. 4).

Apply a flexible silicone sealer e.g. Flowseal 32 to the timber

frame and secure the wall plate using suitable coach bolts,

nuts and washers. On a solid wall installation, apply a fillet

of sealant between the wallplate and wall.

On profile walls it will be neccessary to ‘flash’ the wall plate.

Flashing strips should extend sufficiently to allow fixing to a

high portion of the profile section. Ensure that the flashing

strips over lap at the four corners. Fill between the top and

bottom flashing strips with Neoprene profile filler and seal all

external joints and seams with a suitable flexible silicone sealer

such as Flowsil 32. (See Wallplate dimensions fig. 4b).

1

12. 05. 17. Leaflet Number 670506