2

Installati n and Maintenance ECOSMART Constant Pressure Variable Volume Inline Dampers

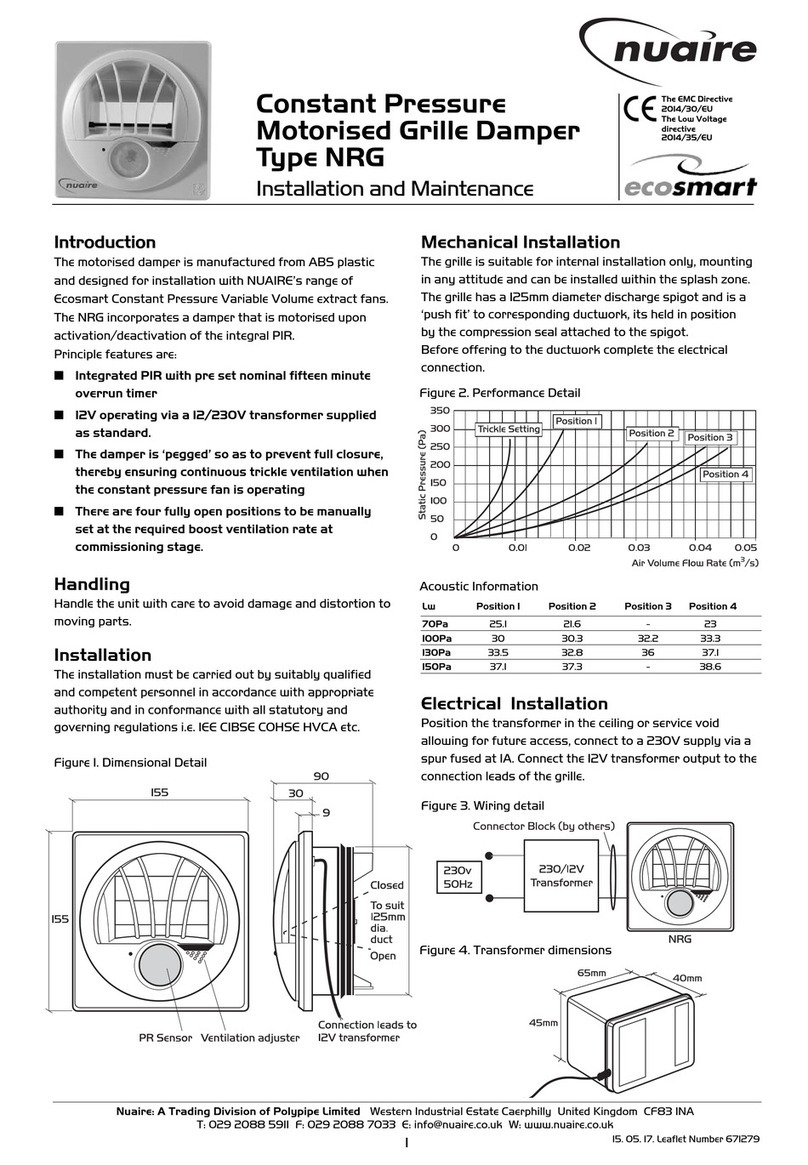

Figure 6. Unit with access panel removed, showing

electrical connection and damper setting positions

Figure 5. Wiring diagram

Technical or commercial considerations may, from time to time, ma e it necessary to alter the design, performance and

dimensions of equipment and the right is reserved to ma e such changes without prior notice.

15. 05. 17. Leaflet Number 671206

(A1) Chee plate.

(A2) Chee plate.

Setting screw (B)

Electrical connections.230V 50Hz 1 phase

Installati n

The installation must be carried out by suitably qualified

and competent personnel in accordance with the

appropriate authority and in conformance with all statutory

and governing regulations i.e. lEE, CIBSE, COHSE, HVCA etc.

Mechanical installati n

The unit can be mounted in any attitude giving due

consideration to the accessibility of the access door to

complete the electrical connection, set up the damper during

commissioning and future maintenance.

A full size access panel is fitted to one side to facilitate

electrical connection and damper setting.

The unit should be coupled directly to ductwor of matching

spigot diameter and installed behind a ceiling or in a service

void and remote from any areas from which it could be

subjected to water spray.

Electrical installati n

The damper is activated by a 230V mains signal, this signal

can be derived from any switching source i.e. light switch,

mains PIR, mains rated thermostat, humidistat etc.

Offer the mains cable via the cable grommet provided

connecting Live (L), Neutral (N) and Earth (E) to the

appropriate terminals

Setting the dampers

Trickle ventilati n; minimum tric le rate is pre set by the

free area cut around the motorised damper. To increase the

tric le ventilation rate remove one of motorised damper

chee plates (A1), to further increase the tric le rate remove

the second chee plate (A2).

Boost ventilation rate is set by adjusting the setting screw

(B), with flow meter connected to duct wor and motorised

damper activated (by switching on power to unit) adjust

the damper position whilst monitoring flow meter until

desired boost airflow rate is achieved.

Maintenance

Maintenance intervals will vary according to the level of

airborne contaminant to which the unit is exposed; chec

three months after commissioning and twelve monthly

thereafter.

There are no parts requiring lubrication.

Isolate the mains supply, remove the access cover and clean

out any dust deposits. Chec the security of all components

and wire terminations - do not adjust the damper setting

screw.

To clean the dampers and internal chamber it will be

necessary to remove the unit from the system and access

through the inlet/outlet spigots, mar the position of the

setting screw (B) and ensure the position is set correctly

upon reinstatement.

There are no recommended spares, should the product

malfunction then it will require total replacement. Order

quoting all the details from the product rating plate.

Warranty

The 3 year warranty starts from the day of delivery and

includes parts and labour for the first year. The remaining 2

years covers replacement parts only.

This warranty is void if the equipment is modified without

authorisation, is incorrectly applied, misused, disassembled,

or not installed, commissioned and maintained in

accordance with the details contained in this manual and

general good practice.

The product warranty applies to the UK mainland and in

accordance with Clause 14 of our Conditions of Sale.

Customers purchasing from outside of the UK should

contact Nuaire International Sales office for further details.

After Sales Enquiries

For technical assistance or further product information,

including spare parts and replacement components, please

contact the After Sales Department.

Telephone 02920 858 400