Allergard Class I

Animal Bedding Disposal Cabinet

Models

NU-608-400E

Operation and Maintenance Manual

Table of Contents

Section No. 1....................................................................General Description

Section No. 2....................................................................Models and Features

Section No. 3....................................................................Warranty

Section No. 4....................................................................Shipments

Section No. 5....................................................................Installation Instructions

5.1......................................................................................Location

5.2......................................................................................Set-Up Instructions

5.3......................................................................................Electrical Services

5.4………………………………………………………………………………….Certification Testing Methods and Equipment

Section No. 6....................................................................Operating the NU-608

6.1…………………………………………………………………………………..Aeromax Control System

6.2…………………………………………………………………………………..Operating Guidelines

6.3…………………………………………………………………………………..Bag Installation and Removal

6.4.......................................................................................Ergonomics

6.5.......................................................................................Cleaning Procedures

Section No. 7....................................................................General Maintenance

7.1.......................................................................................Decontamination

7.2.......................................................................................LED Lamp Replacement

7.3.......................................................................................Filter Replacement

7.4.......................................................................................Motor/Blower Replacement

7.5.......................................................................................Airflow Calibration

7.6.......................................................................................Filter Integrity Check

Section No. 8 ...................................................................Error Messages, Troubleshooting and Option-Diagnostics

Section No. 9………………………………………………………………..Remote Contacts

Section No. 10..................................................................Polycarbonate Material Compatibility

Section No. 11……………………………………………………………….Electrical/Environmental Requirements

Section No. 12……………………………………………………………….Disposal and Recycle

Insert……………………………………………………………..………………Replacement Parts List

Standard Drawings

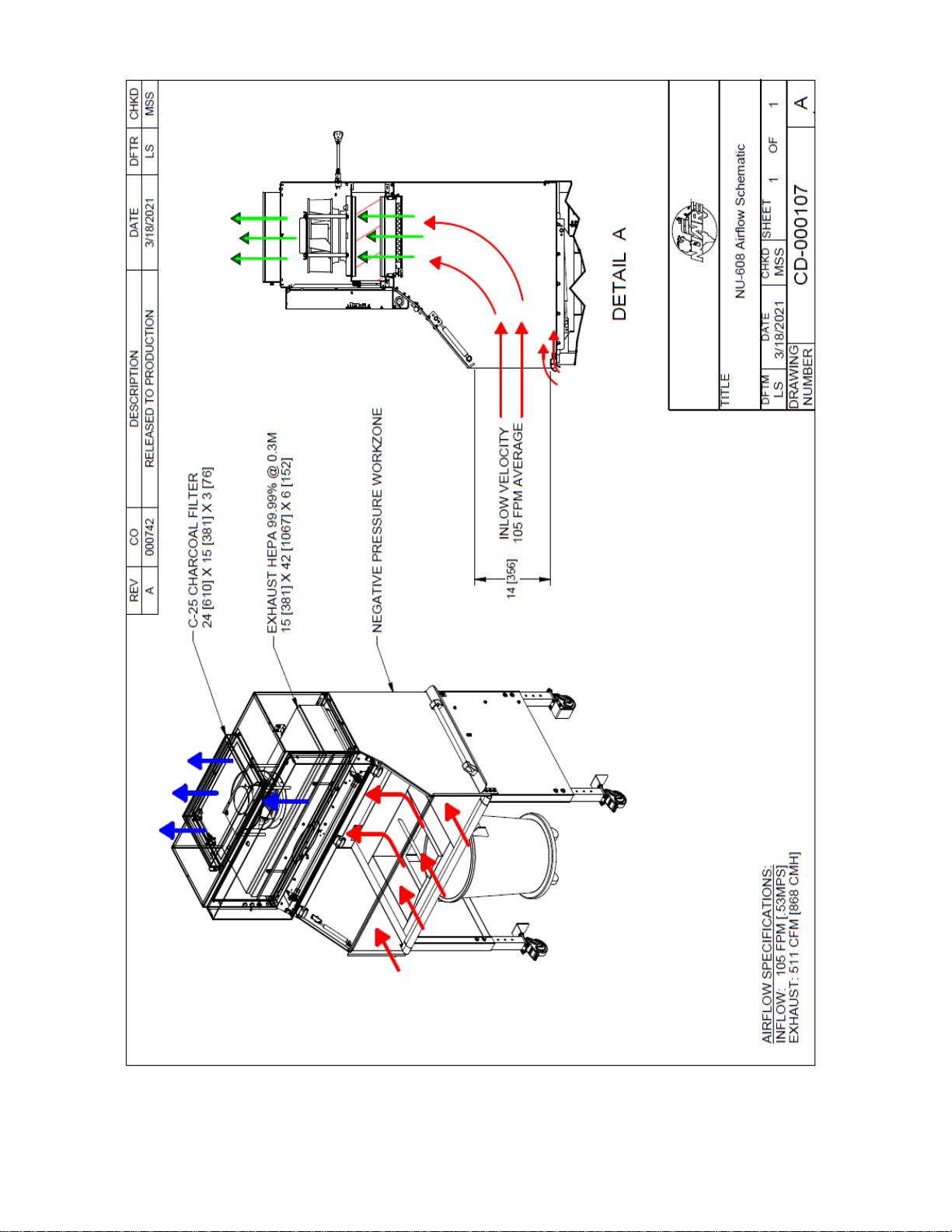

CD-000107..................................NU-608 Airflow Schematic

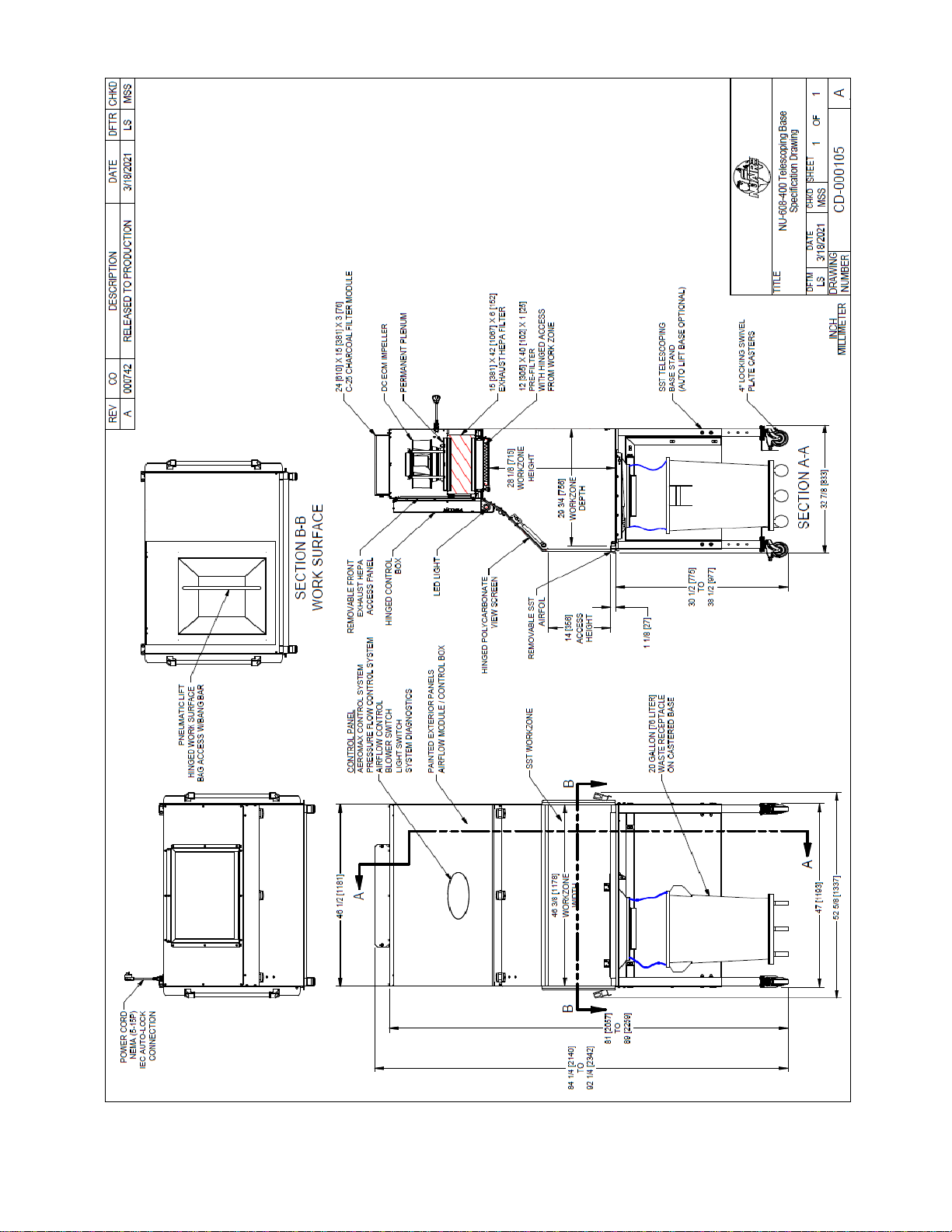

CD-000105..................................NU-608 Spec. Drawing W/Telescoping Base

CD-000109..................................NU-608 Spec. Drawing W/Motorized Base

BCD-16521..................................NU-608 Control Panel

CD-000110..................................NU-608 Final Assembly Drawing

CD-000108..................................NU-608 Electrical Schematic (230VAC)