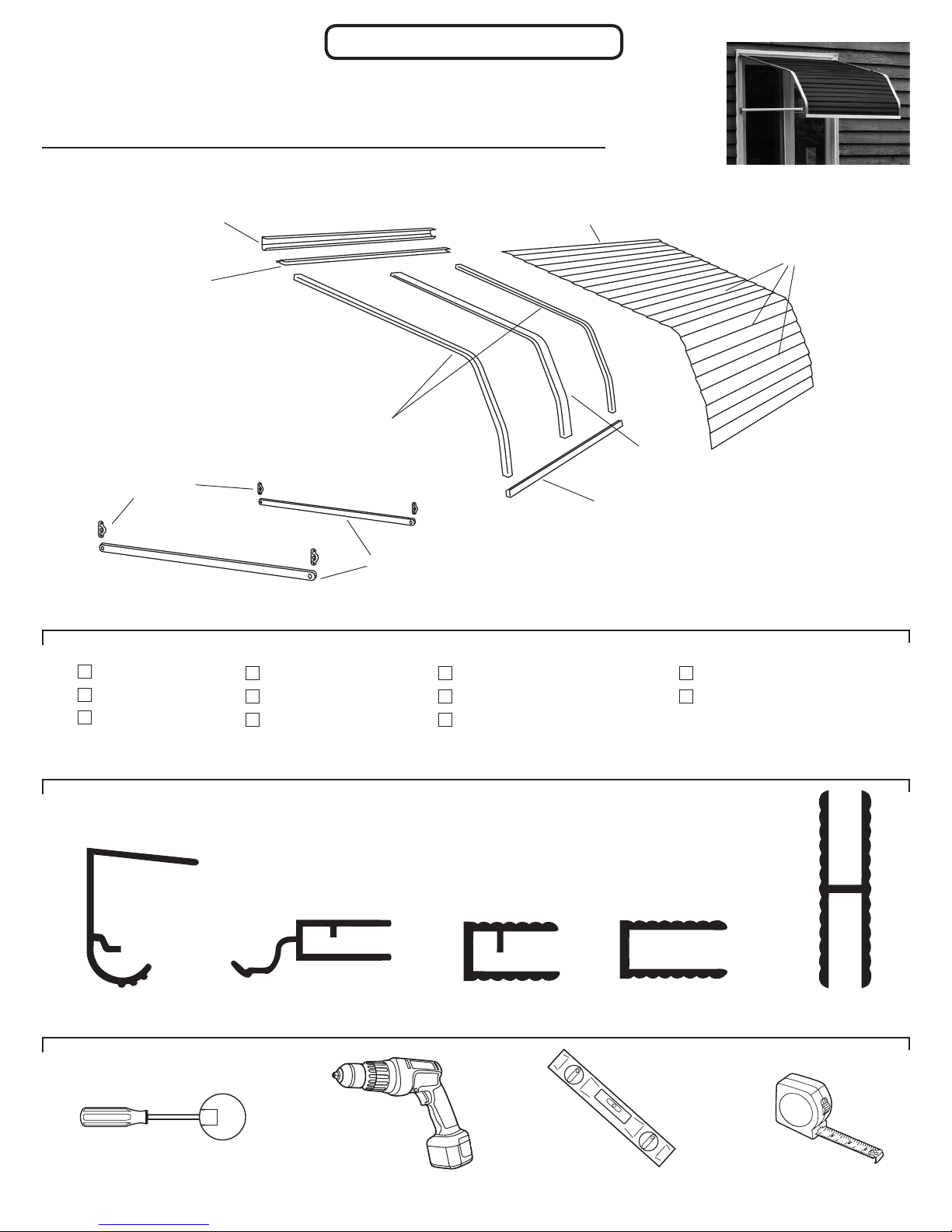

Assembly Instructions Series 4100 Aluminum Casement Window Awning

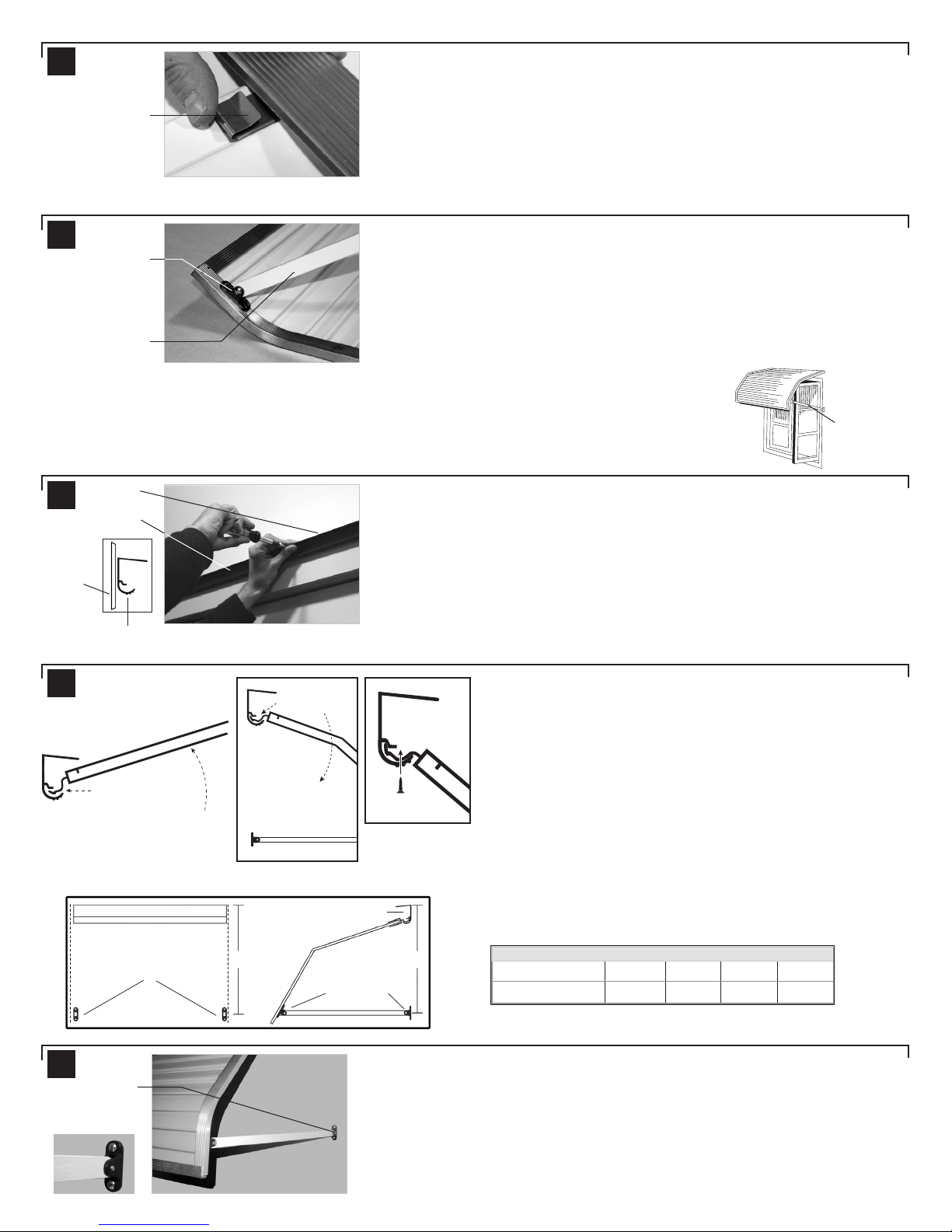

Slide the Top Trim out from Slat Section about 2 inches to provide clearance.

Next, slide the non-curved end of the Edge Rafter onto Top Trim, making sure the

opposite, curved end, of the Edge Rafter is up.

Next, slide both Top Trim and Edge Rafter back toward Slat Section and push

Edge Rafter onto Slat Section edge evenly until Slat Section and Top Trim are

completely FLUSH into Edge Rafter.

Next, fasten small screws in the two larger pre-punched holes along Edge Rafter.

(Pairs of small holes are for sidewing connections for Series 4500.)

NOTE: Support the underside of the Slats Section and apply pressure while fastening

screws.

Repeat Steps 3, 4, and 5 for Edge Rafter assembly on the other side of the awning.

Now attach Center Rafter(s). Align Center Rafter with pre-punched holes in the

center of the Top Trim first and secure with small screws, then do the same at the

other end of the Center Rafter in the center on the Front Trim and secure with

small screws.

NOTE: Window Awnings wider than 60” need more than one Center Rafter, which will

be provided. Pre-punched holes will guide installation of multiple Center Rafters.

Edge

Rafter

Center

Rafter

TIP: Use the palm of your hand flat on

slats, pressing down and pulling toward

you to help snug them into Edge Rafter.

Top Trim

Edge

Rafter

The awning is assembled upside down.

Note that the Slat Sections are packaged

upside down (FIG. 1A). Assemble on a flat

surface.

l

!CAUTION: Awning parts may have sharp

edges. Use care in assembly.

Lay the first slat out, curled edge DOWN on

your left with ends toward you. Slide each

subsequent slat into the curled UP edge on

the right (FIG. 1B).

Slats have a slight

curve to them.

Keep them this

way for assembly.

Slight curve

While keeping Slat Sections flush with each other, crimp slats together at each

seam interlock with a pair of channel lock pliers about 1/4 inch in from the edge

(not too much — only enough to secure them together). Be sure to keep the

plier teeth level with slats so that you do not accidentally bend them up while

crimping.

1

Now, connect the Edge Rafter and Slat Section

with the Front Trim. Again, Slat Section and Front

Trim MUST be FLUSH in the Edge Rafter. With Slat

Section still secured FLUSH in Edge Rafter, slide

Front Trim toward you and flush into the Edge

Rafter, aligning pre-punched holes; it will fit snug.

NOTE: Only the outside edge of the Front Trim and

the curled edge of the slat are inserted into the Edge

Rafter (FIG. 4B).

Next, secure Top Trim and Front Trim with small

screws in the larger pre-punched holes at each

end of the Edge Rafter.

1

2

3

4

5

6

FIG. 1A

FIG. 2

FIG. 3

FIG. 5

FIG. 6

FIG. 1B

Front

Trim

Edge

Rafter

NOTE: It is very important that both ends of the awning (the top trim and the

front trim) along with the slat section are completely flush in the edge rafters to

be able to align pre-punched holes for fastening. See FIG. 4B.

FIG. 4A shows

improper assembly.

These parts are NOT

flush and therefore

will not align to

fasten screws

Slat Section

Assembly

FIG. 4A

FIG. 4B

Parts are

not flush

Parts are

flush

IMPROPER ASSEMBLY PROPER ASSEMBLY