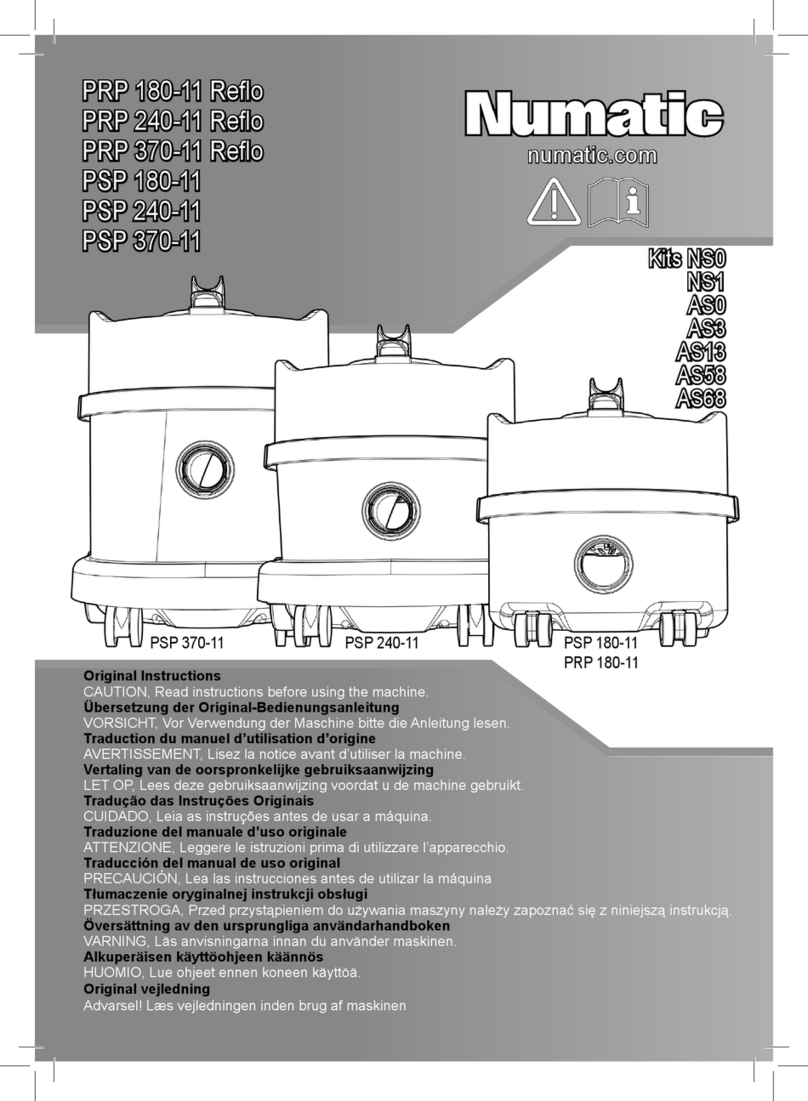

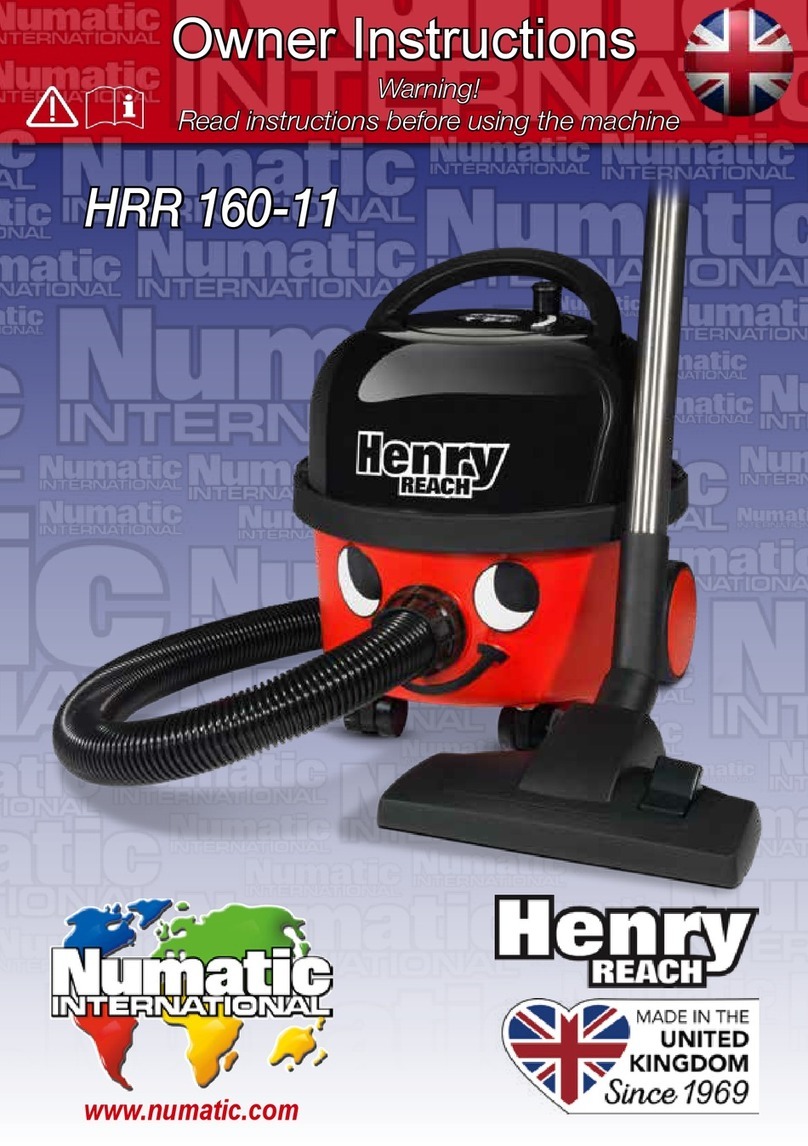

Information for DRY use Vacuum cleaners

WARNING

Read the instruction manual before using the machine.

Operators shall be adequately instructed on the use of these machines.

As with all electrical equipment, care and attention must be exercised at all times during use, in

addition to ensuring that routine and preventative maintenance is carried out periodically to ensure safe

operation.

Failure to carry out maintenance as necessary, including the replacement of parts to the correct standard

could render this equipment unsafe and the manufacturer can accept no responsibility in this respect.

This machine is for DRY USE only and must not be stored outside or used in wet conditions.

cleaning or maintenance and when replacing parts or converting the machine to another function.

This machine is not to be used by children or persons with reduced physical, sensory or mental

Children should be supervised to ensure they do not play with the machine

This machine is not a toy.

CAUTION

This machine is for use indoors only.

This machine should be stored indoors only.

NOTES

This machine is also suitable for commercial use, for example in hotels, schools, hospitals,

This product complies with the requirements of clause 20 of EN 60335-2-69 Stability and

Mechanical Hazards.

DO

• Keep your machine clean.

•

•

•

• Keep hoses and tubes clear.

• Replace any worn or damaged parts immediately.

•

• Change dust bag frequently.

• Only use the brushes provided with the machine. The use of other brushes may impair safety.

• Only replace the power cord with the correct Numatic approved replacement part.

DO NOT

• -

• Unreel the cable with one pull or pull on the cable to unplug the machine from the power supply.

•

• Use steam cleaners or pressure washers to clean the machine or use in the rain.

• Immerse in water for cleaning.

• Attempt machine maintenance or cleaning unless the power supply plug has been removed from

the supply outlet.

•