© 2018 nVent 89074457

- 2 -

WARRANTY AND RETURN POLICY

Visit hoffman.nVent.com/warranty-information

TABLE OF CONTENTS

Warranty and Return Policy............................................................................................................................................................. 2

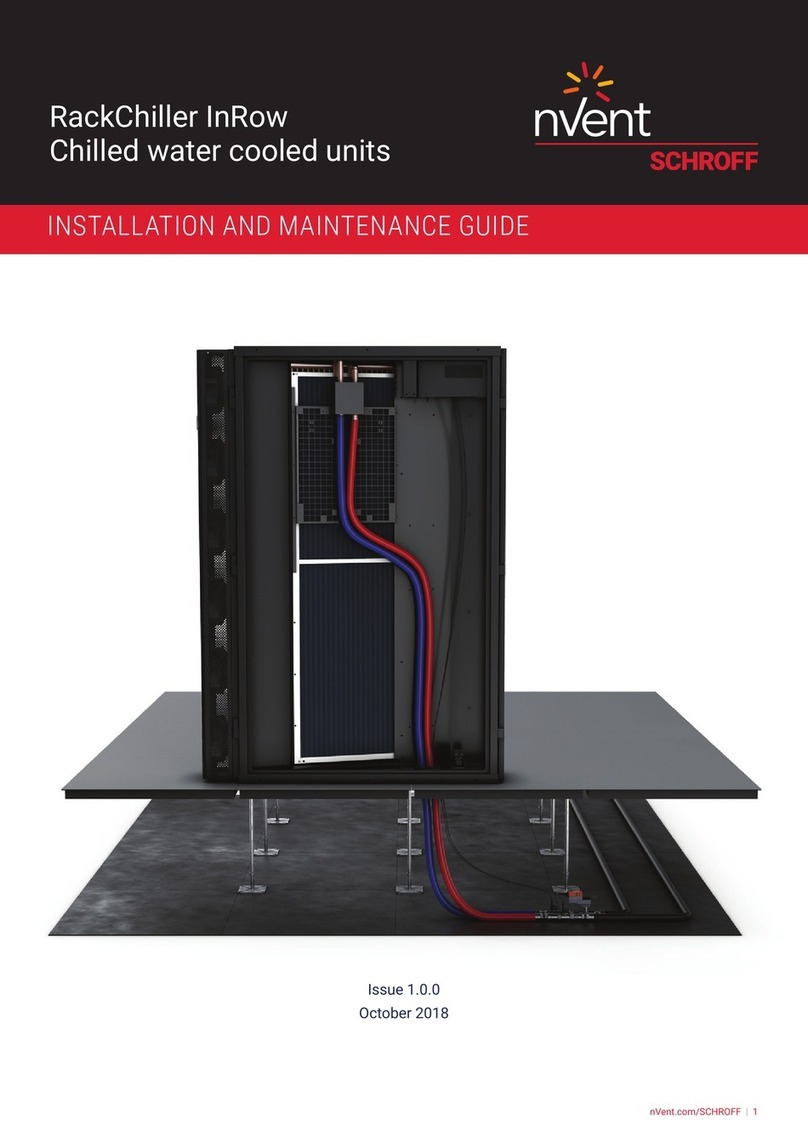

HOW TO UNPACK THE ENCLOSURE.............................................................................................................................................. 3

LEVELING THE EQUIPMENT........................................................................................................................................................... 3

SPECIFICATIONS ............................................................................................................................................................................. 4

Design Data..................................................................................................................................................................................................... 4

SERVICE PARTS .............................................................................................................................................................................................. 5

Dimensional Drawings ................................................................................................................................................................................... 6

78x24x42 In-row Cooling Unit, 31kW.................................................................................................................................................... 6

78x36x42 In-row Cooling Unit, 52kW.................................................................................................................................................... 7

Wire Diagram................................................................................................................................................................................................... 8

ELECTRICAL CONNECTIONS.......................................................................................................................................................... 9

MOTOR CONTROL CARD CONNECTION ....................................................................................................................................... 9

MINIMUM AND MAXIMUM OPERATING CONDITIONS................................................................................................................ 9

CONDENSATE PUMP WIRING ........................................................................................................................................................ 9

WATER QUALITY.............................................................................................................................................................................. 9