4BIA-nXt-PROTECT1 Instruction Manual

1. Introduction

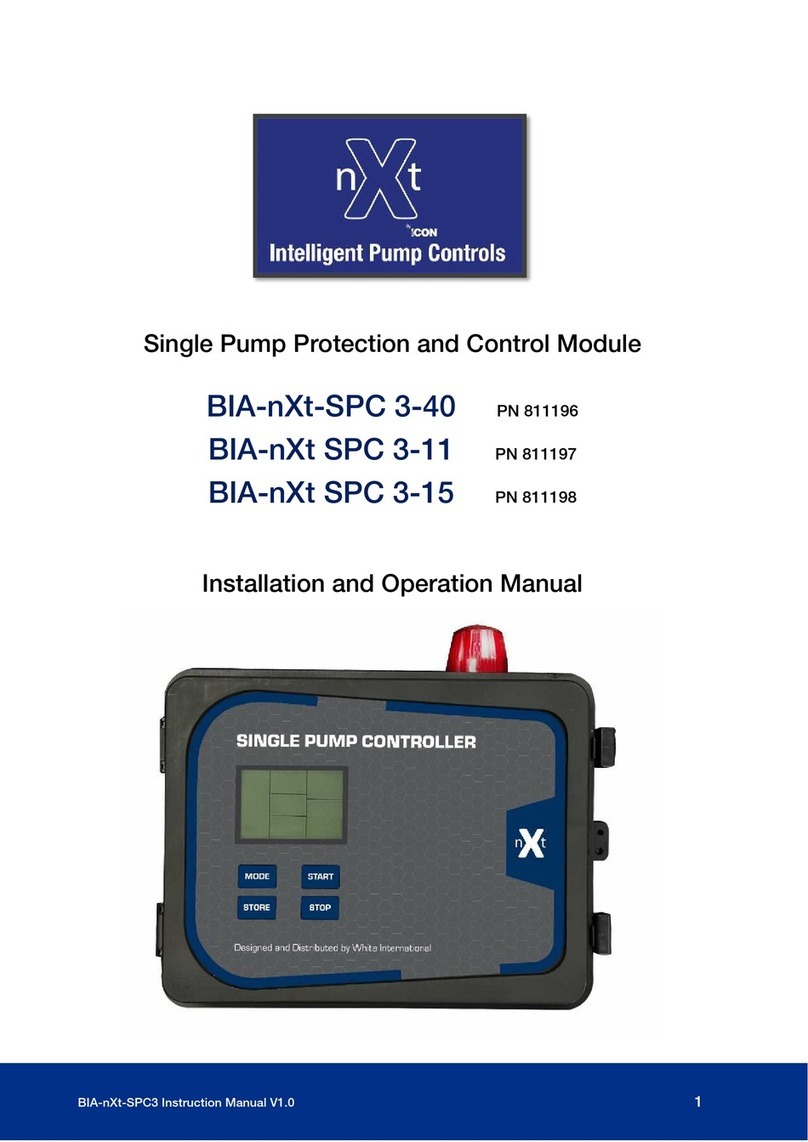

Thank you for choosing a Bianco nXt-Protect single pump control and protection module.

The nXt-Protect is a module intended to control and protect an individual single phase

pump. The user can select a control logic sequence to match their application and enjoy the

benefits of superior control and protection for the pumps.

There are 3 primary control logic modes:

•‘Drainage’ where control is concentrated at the source

•‘Boosting’ which references pressure switching on the delivery side for control

•‘Transfer’ which is a mix of source and destination control

The LCD screen displays the pump running state and provides the user a wealth of useful

information.

The controller is easy to set up with an initial push button calibration and individual

parameters can be fine-tuned.

A nXt-Protect controller is particularly useful where there is the need to control and protect

pump installations managing the automatic operation through a variety of switching

methods without the need to create a bespoke control solution.

2. Warnings and Cautions

Read the manual carefully before starting

Prior to starting installation or maintenance the controller must be

disconnected from the power supply.

Any changes or modification to the wiring must be carried out by

competent, skilled and suitably qualified personnel only.

A qualified electrician should correctly size and install circuit breakers

to protect the power supply. The fitment of additional surge protection

is recommended as good practice.

Never open the cover while controller is connected to electrical supply.

Disconnect and allow the internal electronics to discharge before

opening the cover

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not

play with the appliance.

Ensure the controller is a suitable size for the pump motor (see

Section 6, Page 7: Technical Data). Size according to full load

current amperage.(P1 power)