Parts List

For general information regarding where to get parts and suggested part numbers please see

our useful Parts Guide at the project webpage or http://www.oakleysound.com/parts.pdf.

The components are grouped into values, the order of the component names is of no particular

consequence.

A quick note on European part descriptions. R is shorthand for ohm. K is shorthand for kilo-

ohm. R is shorthand for ohm. So 22R is 22 ohm, 1K5 is 1,500 ohms or 1.5 kilohms. For

capacitors: 1uF = one microfarad = 1000nF = one thousand nanofarad.

To prevent loss of the small ‘.’ as the decimal point, a convention of inserting the unit in its

place is used. eg. 4R7 is a 4.7 ohm, 4K7 is a 4700 ohm resistor, 6n8 is a 6.8 nF capacitor.

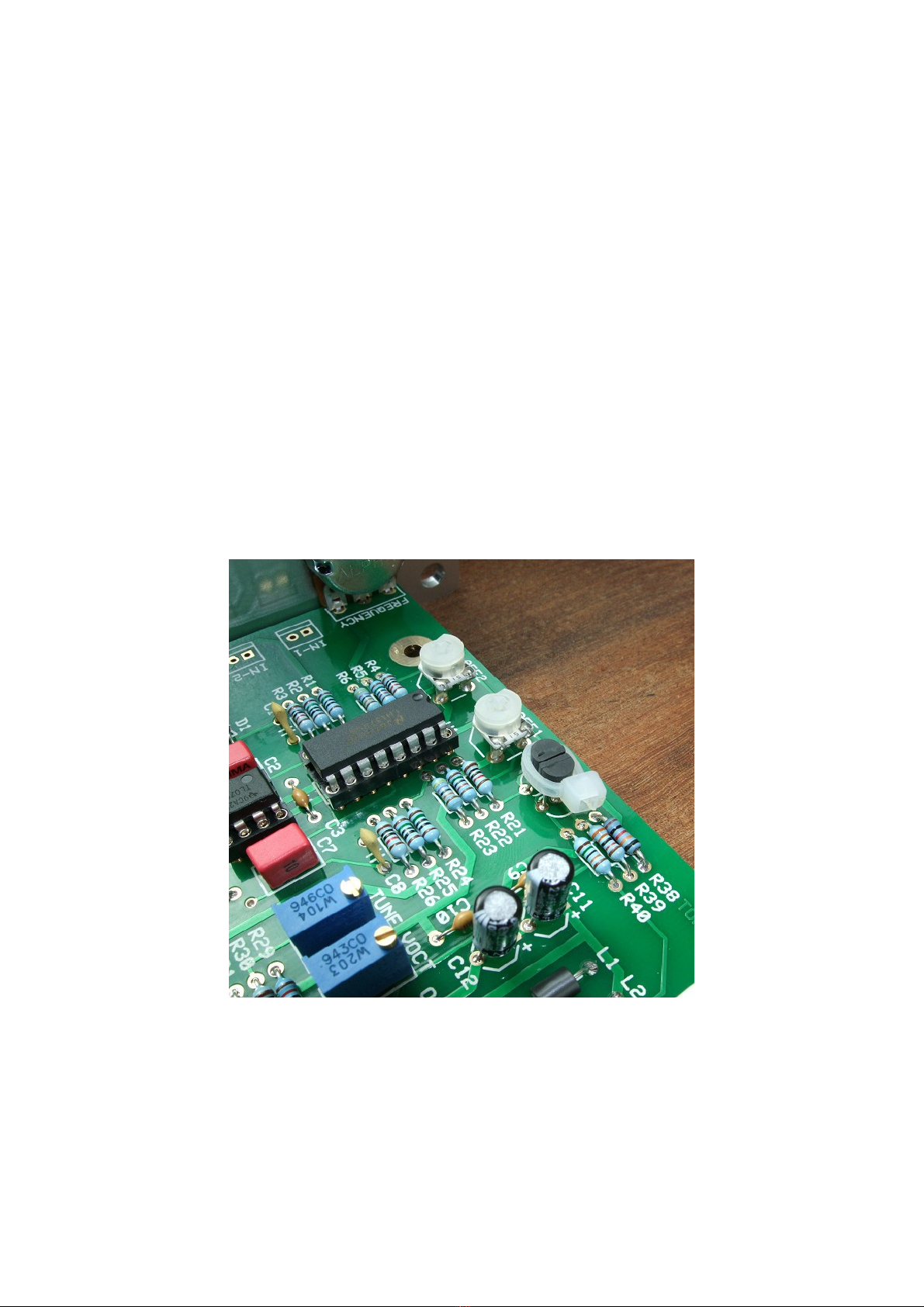

Resistors

All resistors should be 0.25W 1% metal film (MF) types unless stated.

150R R25, R2, R24, R1

1K R27, R47, R48, R36

1K +3000ppm/k PTC R38

10K R21, R4, R16, R18, R26, R3

15K R5, R22

27K R7

33K R39

47K R42, R37, R45, R44, R28, R14, R19, R15

62K R12

82K R43, R17, R41, R46

100K R33, R20, R8, R34, R9

130K R29

150K R40

220K R35

330K R10, R11, R13*

470K R23, R6

560K R32

1M R31, R30

* R13 fitted only in 2U version

Capacitors

100nF, 63V axial ceramic C3, C4, C5, C6, C9, C10, C13, C14

4p7 C0G ceramic* C1, C8

470pF C0G ceramic 5mm** C2, C7

2.2uF, 35V electrolytic C11, C12

5