3

We reserve the right to modify product specifications without prior notice. HC308-INS-02 2822© Oasis Engineering Limited

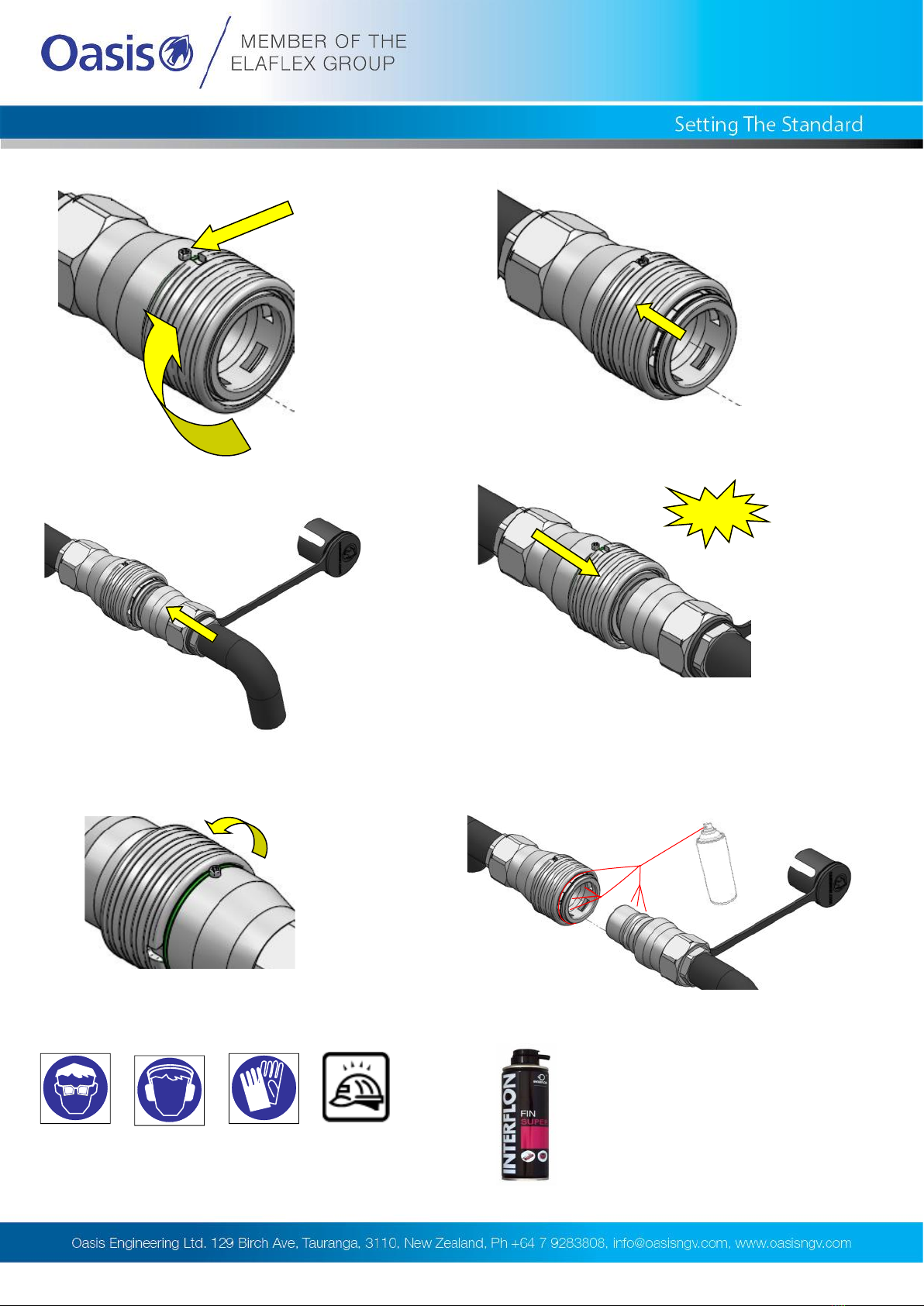

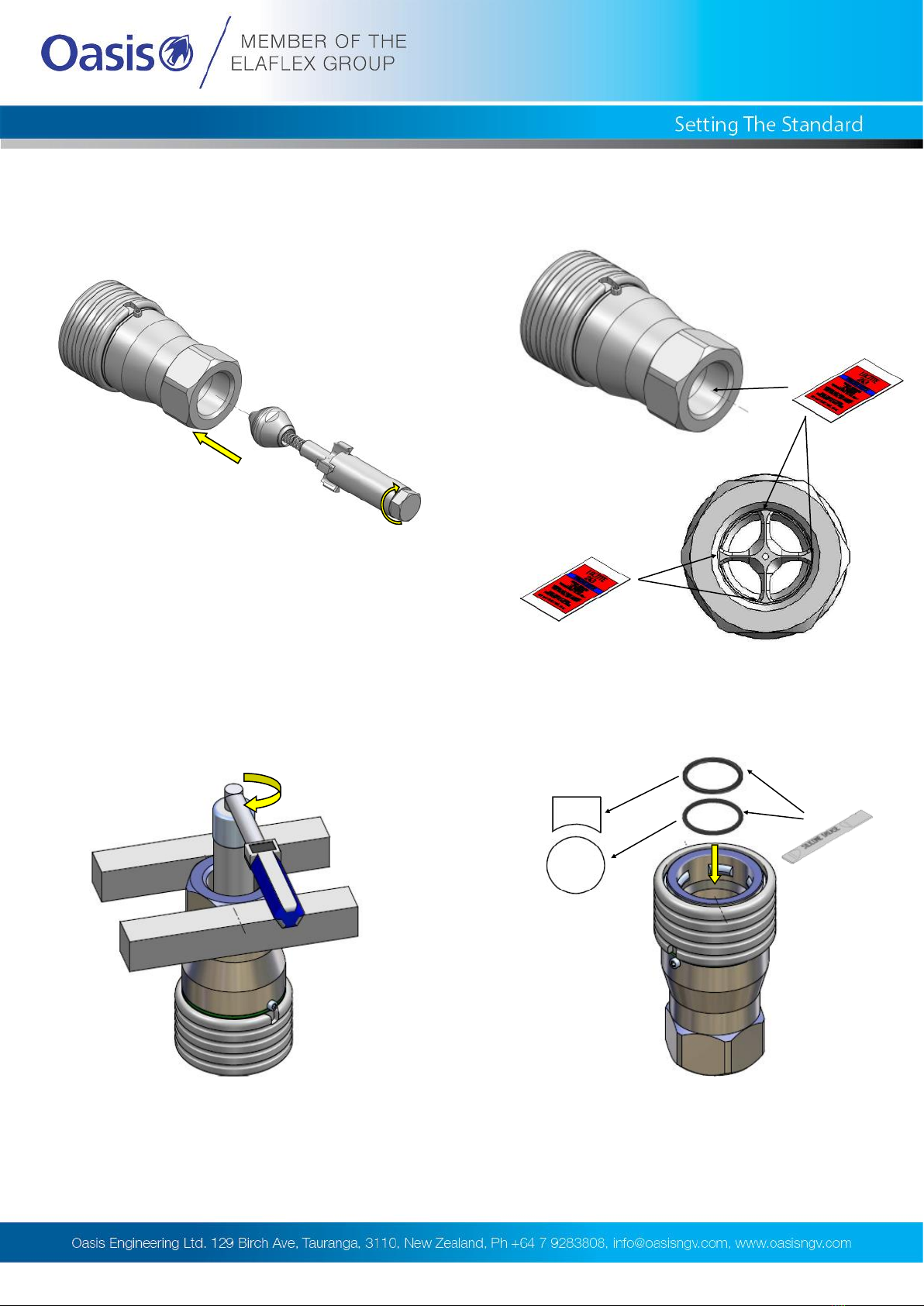

Installation

Instructions

1. Apply thread tape and thread sealant.

4. Apply thread tape and thread sealant.

5. Place dust cap over fitting. Join and tighten

the connection.

Ensure it does not cross thread.

2. Join and tighten the connection.

Check for leaks on first

use with snoop or soapy

water.

Check for leaks on first

use with snoop or soapy

water.

3 to 4 turns

Please ensure that the tape

covers all threads, but does not

overlap the end of the fitting

(Optional)

If galling is a concern or unable to cover all

threads, apply a light coating over thread tape

and uncovered threads.

3. Complete.

Tighten connection

hand tight before apply

two full turns with

wrench

3 to 4 turns

Please ensure that the tape

covers all threads, but does not

overlap the end of the fitting

(Optional)

If galling is a concern or unable to

cover all threads, apply a light

coating over thread tape and un-

covered threads.

6. Complete. Put dust cap over

male end when uncoupled.

Tighten connection

hand tight before apply

two full turns with

wrench

We reserve the right to modify product specifications without prior notice. HC308-INS-02 2822© Oasis Engineering Limited