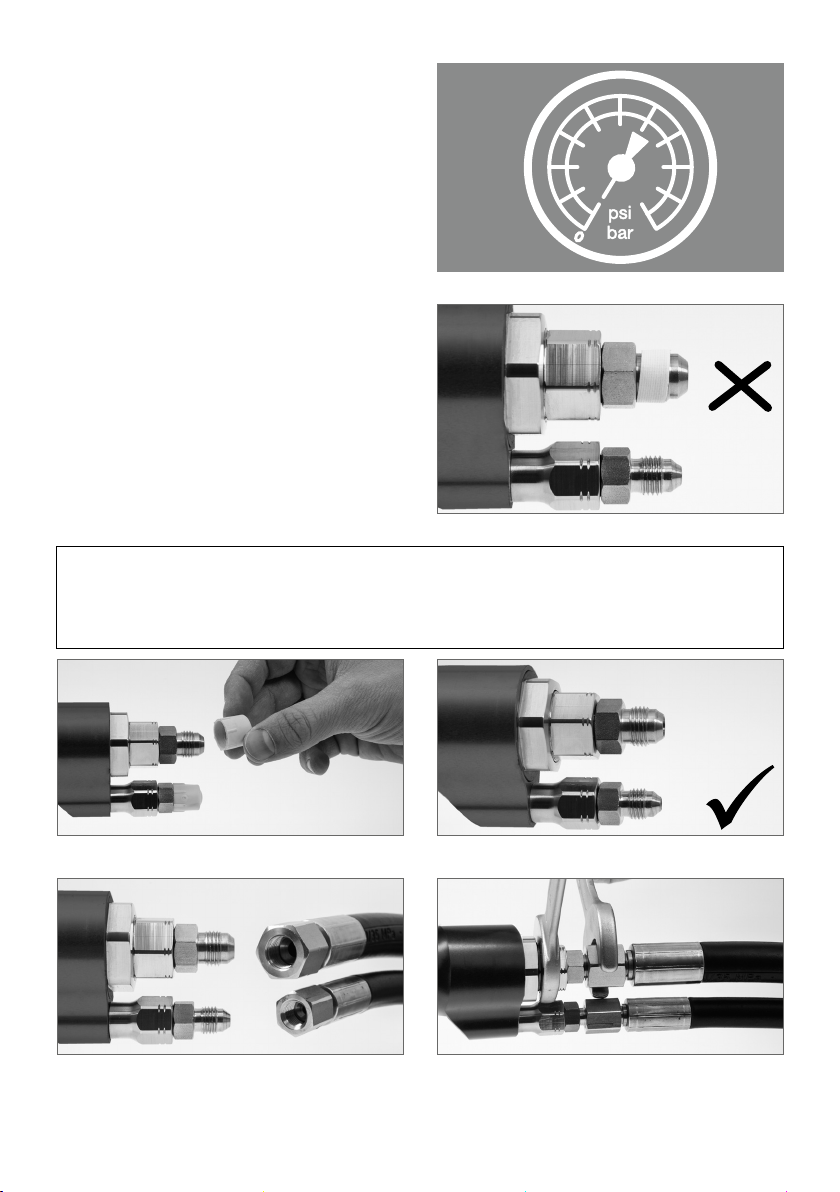

FILL POINT ADAPTERS

The use of fill point adapters is strictly prohibited.

MAINTENANCE

The N-CNG nozzle is a mechanical device that may become inoperative due to wear, corrosion and

ageing of components. Regular inspections and maintenance are essential for a safe operation.

Daily visual inspections of the nozzle by trained personnel should be carried out to ensure proper

function. The nozzle coupling shall be clean and not show any signs of damage (e.g. dents, sharp

edges, blocked lever, swivel non-rotating). Especially check the inner area of the front coupling part

of the nozzle to confirm there is no dirt or mechanical damage. If there are issues with latching, it is

an indication that the gating latch must be replaced. If the operation of the nozzle handle is excessively

tight, or requires more force to actuate than normal after a period of use, a trained personnel is

required to re-lubricate the nozzle with grease as per the servicing instructions.

The nozzle condition shall be thoroughly checked during the annual pump maintenance by competent

personnel. Applicable laws, regulations and Codes of Practice have to be followed. Nozzles in unfit

condition for use must be immediately replaced. The nozzle should be inspected for damage or leaks

every 20,000 cycles or one year, whichever happens first. In case of an abnormality it should be

serviced by the manufacturers authorized service centre. In addition, it should be serviced by the

manufacturers authorized service centre after every 40,000 filling cycles as per ISO 14469:2017 or

every four years, which ever happens first.

CONDITIONS OF USE

Failure to comply with any warnings, instructions, procedures or any other common sense procedures

may result in injury, equipment damage, property damage or poor performance of the equipment.

Oasis accepts no liability for direct, indirect, incidental, special, or consequential damages resulting

from failure to follow any warnings, instructions and procedures in this manual, or any other common

sense procedures generally applicable to equipment of this type. The foregoing limitation extends to

damages to person or property caused by the unit or damages resulting from the inability to use the

unit including loss of profits, loss of products, loss of power supply, the cost of arranging an alternative

power supply, and loss of time, whether incurred by the user or their employees, the installer, the

commissioner, a service technician, or any third party. The manufacturer reserves the right to change

the specifications of its products or the information in this manual without necessarily notifying its users.

Variations in installation and operating conditions may affect the unit‘s performance. Oasis has no control

over each installation‘s unique operating environment. Hence, no representations or warranties concerning

the performance of the unit under the actual operating conditions prevailing at the installation are made.

A technical expert of your choosing should validate all operating parameters for each application.

Oasis has made every effort to explain all servicing procedures, warnings, and safety precautions as clearly

and completely as possible. However, due to the range of operating environments, it is not possible to

anticipate every issue that may arise. This manual is intended to provide general guidance. For specific

guidance and technical support, contact your authorized supplier or specialist service contractor.

Only approved original parts shall be used and no unauthorised modifications to the hardware shall

be made. The use of non-approved parts or modifications will void all warranties and approvals. The

use of non-approved parts or modifications may also constitute a safety hazard. Information in this

manual shall not be deemed a warranty, representation, or guarantee. For warranty provisions appli-

cable to this unit, please refer to the warranty provided by the supplier.

Every effort has been made to ensure the accuracy of this document. However, it may contain technical

inaccuracies or typographical errors. Oasis assumes no responsibility for and disclaims all liability of

such inaccuracies, errors or omissions in this.

7