Copyright Information

Copyright © 2007 - 2013 by Obvius

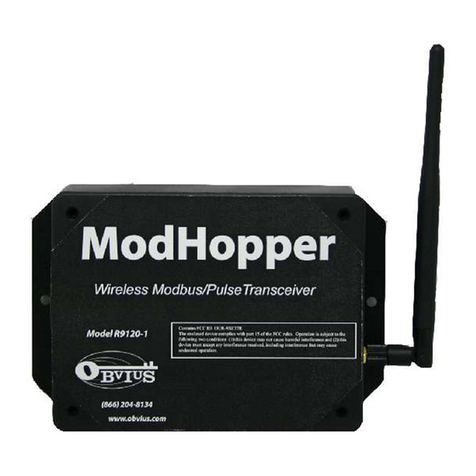

Obvius, AcquiSuite and ModHopper are trade arks of Obvius Holdings LLC

Other brand and product na es are trade arks or registered trade arks of their respective holders.

U.S. Government Restricted Rights: Use, duplication or disclosure by the Govern ent is subject to restrictions set fourth in subparagraph (a) through

(d) of the Co ercial Co puter Restricted Rights clause at FAR 52.227-19 when applicable, or subparagraph (c) (1) (ii) of the Rights in Technical Data

and Co puter Software clause at DFARS 252.227-7013, and in si ilar clauses in the NASA FAR Supple ent.

Limited Warranty

OBVIUS IS PROVIDING THIS WARRANTY IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS BUYER'S EXCLUSIVE REMEDY FOR ALL

CLAIMS AGAINST OBVIUS. OBVIUS SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES. OBVIUS'S TOTAL

LIABILITY FOR ALL CLAIMS SHALL BE LIMITED TO THE PRICE PAID FOR ITS PRODUCT.

Obvius pro ises buyer that any standard product anufactured by Obvius shall be free fro all aterial defects in design, aterial, or anufacturing for

a period of 2 years fro the anufacture date; provided, however, that the warranty shall not extend to ordinary wear and tear or to nor ally replaceable

co ponents (e.g., batteries). During the warranty period, Obvius ay repair or replace (in its sole discretion) any product suffering fro a warranty defect

and returned freight prepaid by buyer, with no charge to buyer for any warranty repair or replace ent. The warranty shall re ain in full force and effect

for such 2 year period, provided that the product: (1) was installed, operated, and aintained properly; (2) has not been abused or isused; (3) has not

been repaired, altered, or odified outside of Obvius's authorized facilities; (4) has not been sold subject to other warranty ter s specified at the ti e of

sale; and (5) is still owned by the original purchaser. This warranty provides specific legal rights that ay be varied by state law. Obvius's products are not

designed for life or safety applications.

Product Application Limitation

Obvius strongly believes in continuous i prove ent, therefore we ust reserve the right to change specifications and product offerings without notice.

Where possible, we will substitute products with equivalent functionality when necessary.

DANGER

Hazard of Electric Shock, Explosion or Arc Flash

●Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

●This equipment must only be installed and serviced by qualified electrical personnel.

●Read, understand and follow the instructions before installing this product.

●Turn off all power supplying equipment before working on or inside the equipment. Use properly rated voltage sensing device to

confirm power is off. DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

●Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

NOTICE

●This product is not intended for life safety applications.

●Do not install this product in hazardous or classified locations.

●The installer is responsible for conformance to all applicable codes.

●Mount this product inside a suitable fire and electrical enclosure.

FCC Part 15 Information

Note: This equipment has been tested by the manufacturer and found to comply with the limits of a class A digital device, pursuant to part

15 of the FCC rules. These limits are designed to provide reasonable protection against interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Modifications of this product without the express authorization of Obvius nullify this statement.

Page 2 A90DC-12 – DC Current Monitor

www. .com information@itm.com1.800.561.8187