SAFETY PRECAUTIONS

DO NOT operate, maintain or repair this unit without having fully read

and understood ALL the aspects of this manual.

DO NOT ride, sit or stand on unit at anytime.

DO NOT modify the leaf vacuum for any reasons to allow for riders.

DO NOT operate the unit in a state of disrepair.

DO NOT operate the unit with ANY guards or safety devices broken,

missing, or inoperable.

DO NOT operate the unit without wearing proper safety equipment.

DO NOT operate this unit while under the influence of any alcohol or

medication.

DO NOT operate this unit if you have a record of mental instability or

dizziness which could result in injury to yourself or others.

DO NOT operate this unit if you are under 18 years of age.

DO NOT operate this unit without fully inspecting the unit for any dam-

age or leakage.

DO NOT operate if the unit has any excessive vibration.

DO NOT operate unit with the inspection door limit switch damaged or

missing.

DO NOT operate unit unless it is properly connected to a leaf collection

box.

DO NOT operate unit unless it is properly attached to the tow vehicle.

DO NOT tow unit without using all the safety chains.

DO NOT tow unit with a damaged tongue.

DO NOT fill fuel tank with engine running. Allow engine to cool for 5

minutes before refueling.

DO NOT operate unit if fuel is spilled or with fuel cap off.

DO NOT smoke or weld near the unit.

DO NOT run engine in an enclosed area.

DO NOT place hands or feet near moving or rotating parts.

DO NOT operate engine with an accumulation of grass, leaves or other

debris on the engine.

Read and understand this entire manual before operating, maintain-

ing or repairing the leaf vacuum.

1.2 DO’S AND DO NOT’S:

This section contains some general safety precautions to do and not to do.

This is not an all inclusive list and and it is the responsibilty of the operator

to have proper training and use common sense in work situations.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

DO NOT:

ODB COMPODB COMP

ODB COMPODB COMP

ODB COMPANYANY

ANYANY

ANY

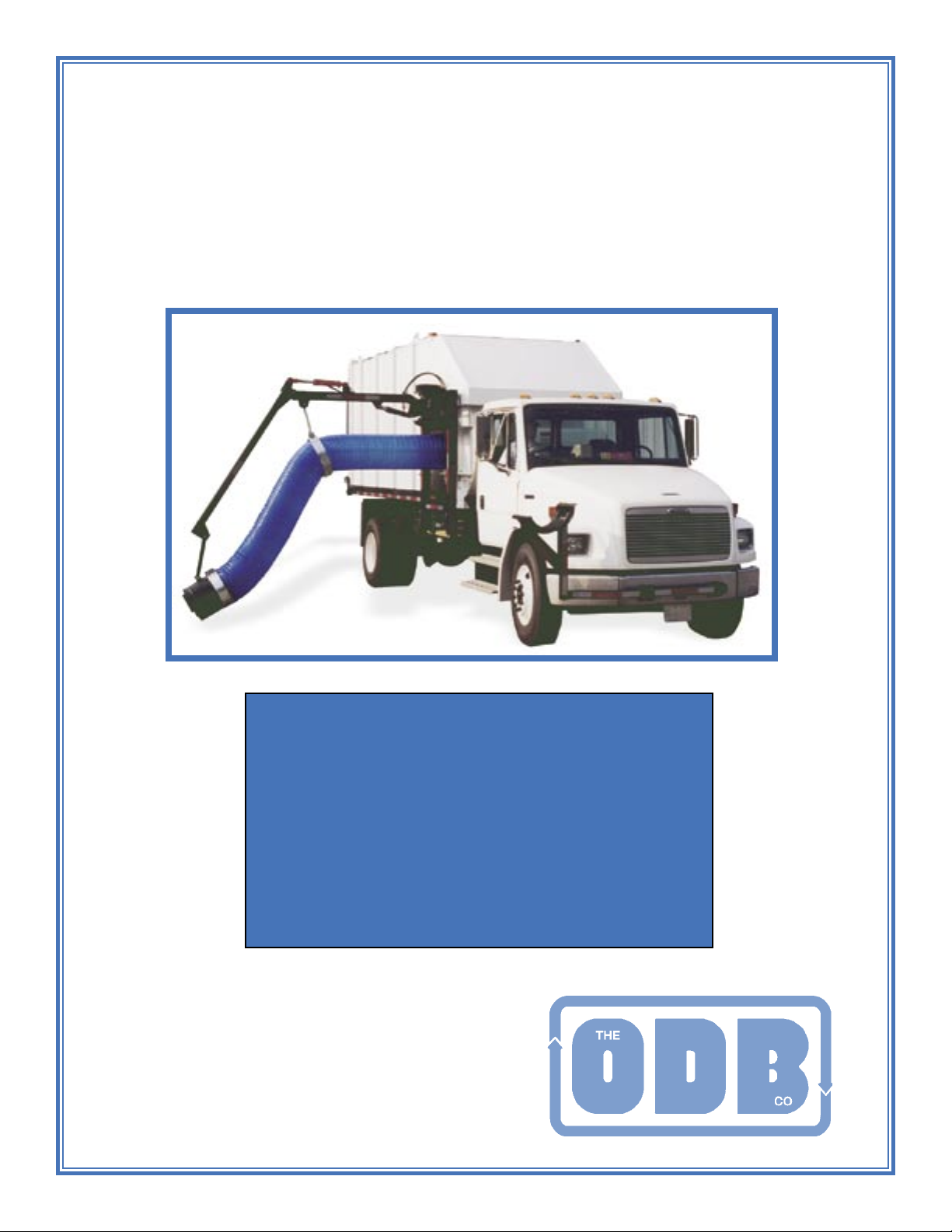

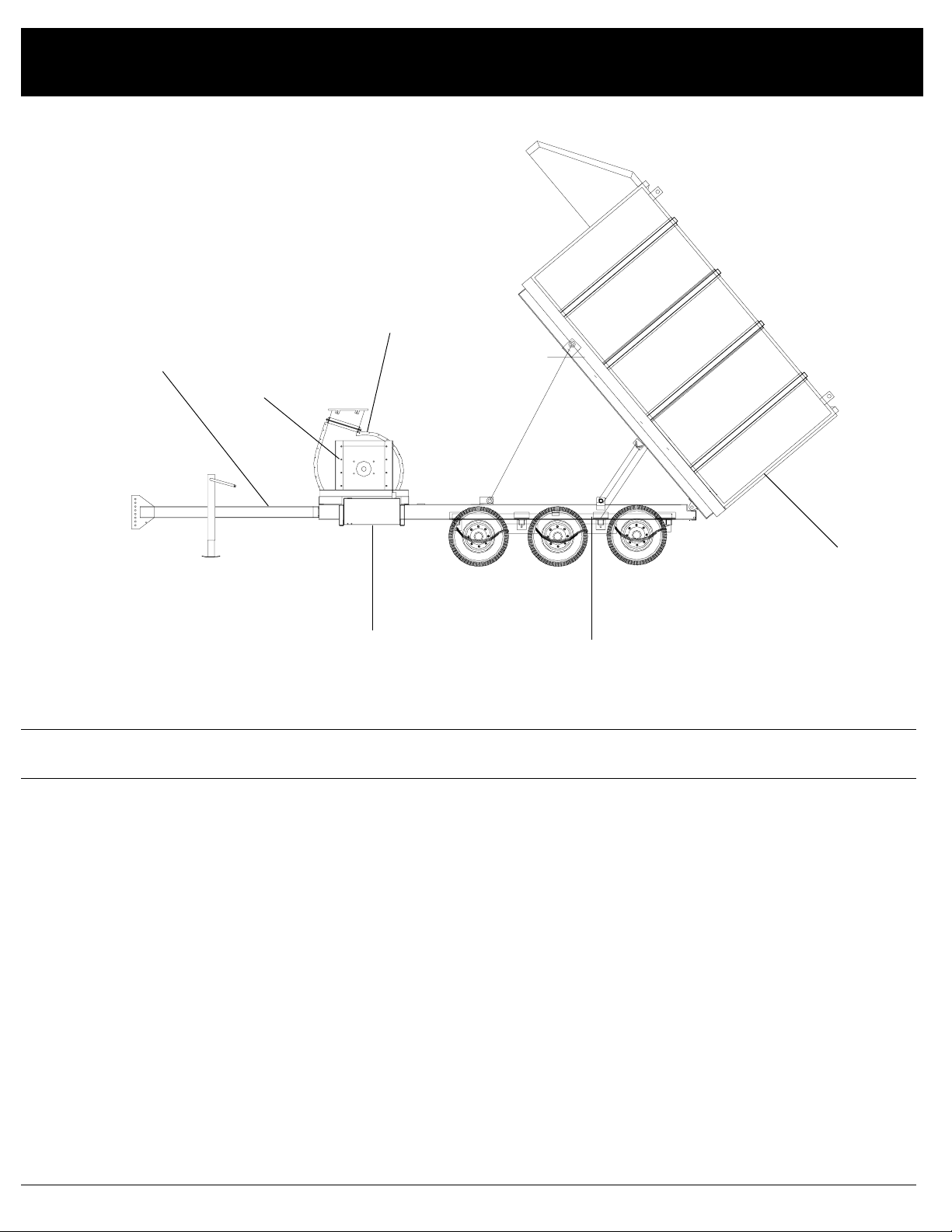

Manufactured by