5

Planetary Final Drive Service Manual

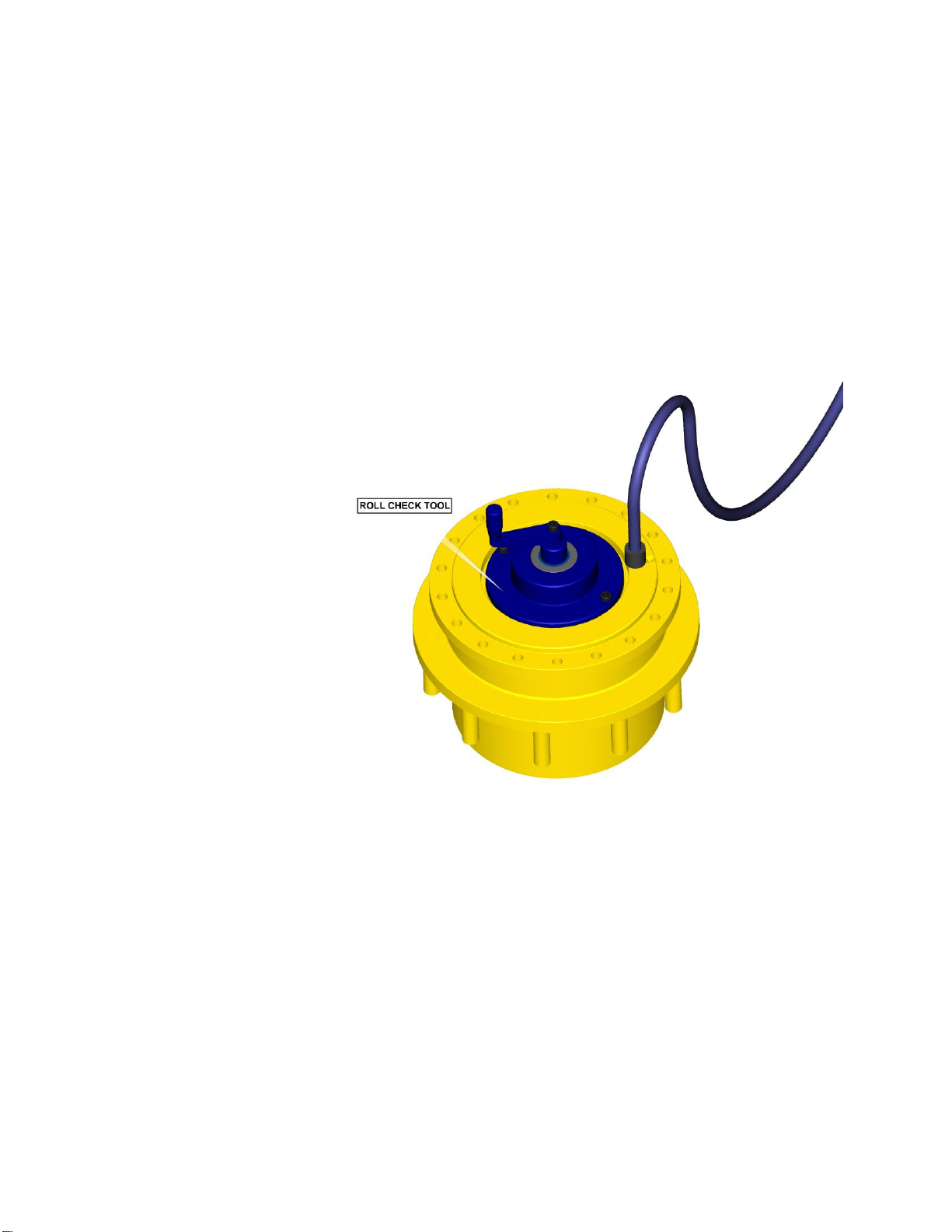

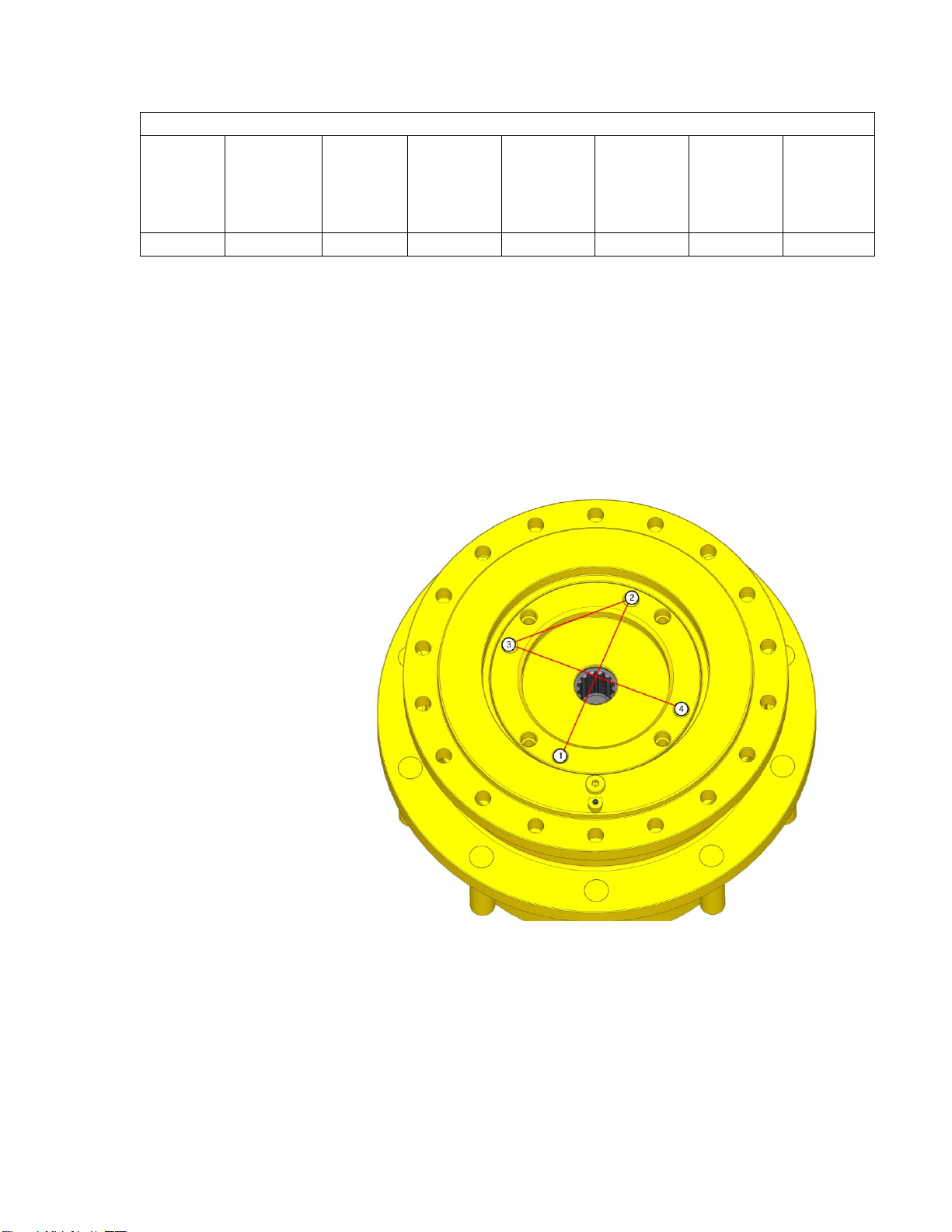

Brake Test

The Brake Test To perform a brake check, use a M12x1.5 metric fitting. Install a

hydraulic hand pump with pressure gauge into brake port in spindle

(1A) using metric thread fitting.

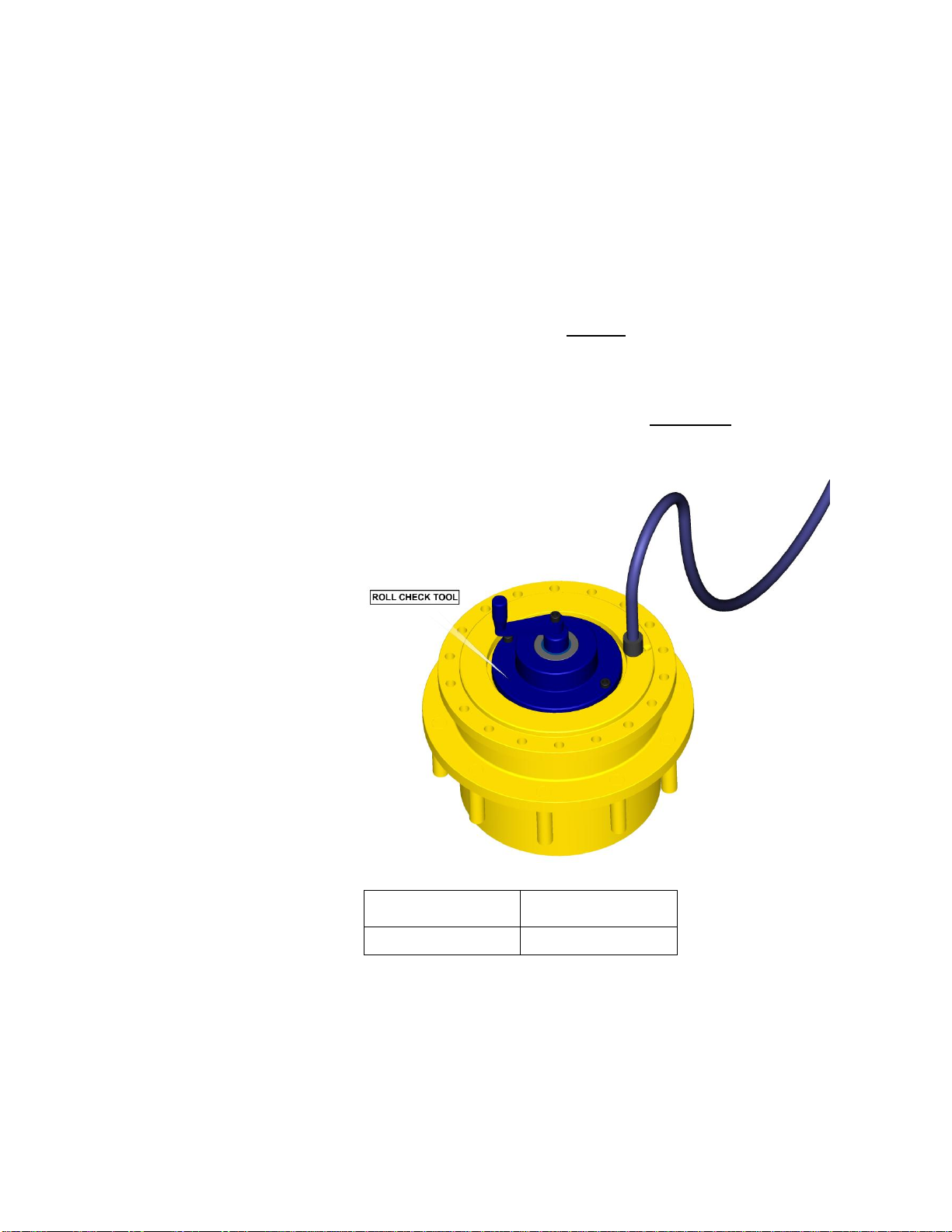

Place ROLL TEST Tool (refer to table on page 9) into input

coupling.

Apply 25 in-lbs torque. While trying to rotate tool, pump the handle

on the hydraulic hand pump and increase the pressure until the

brake releases. The brake is released when you are able to rotate

the tool.

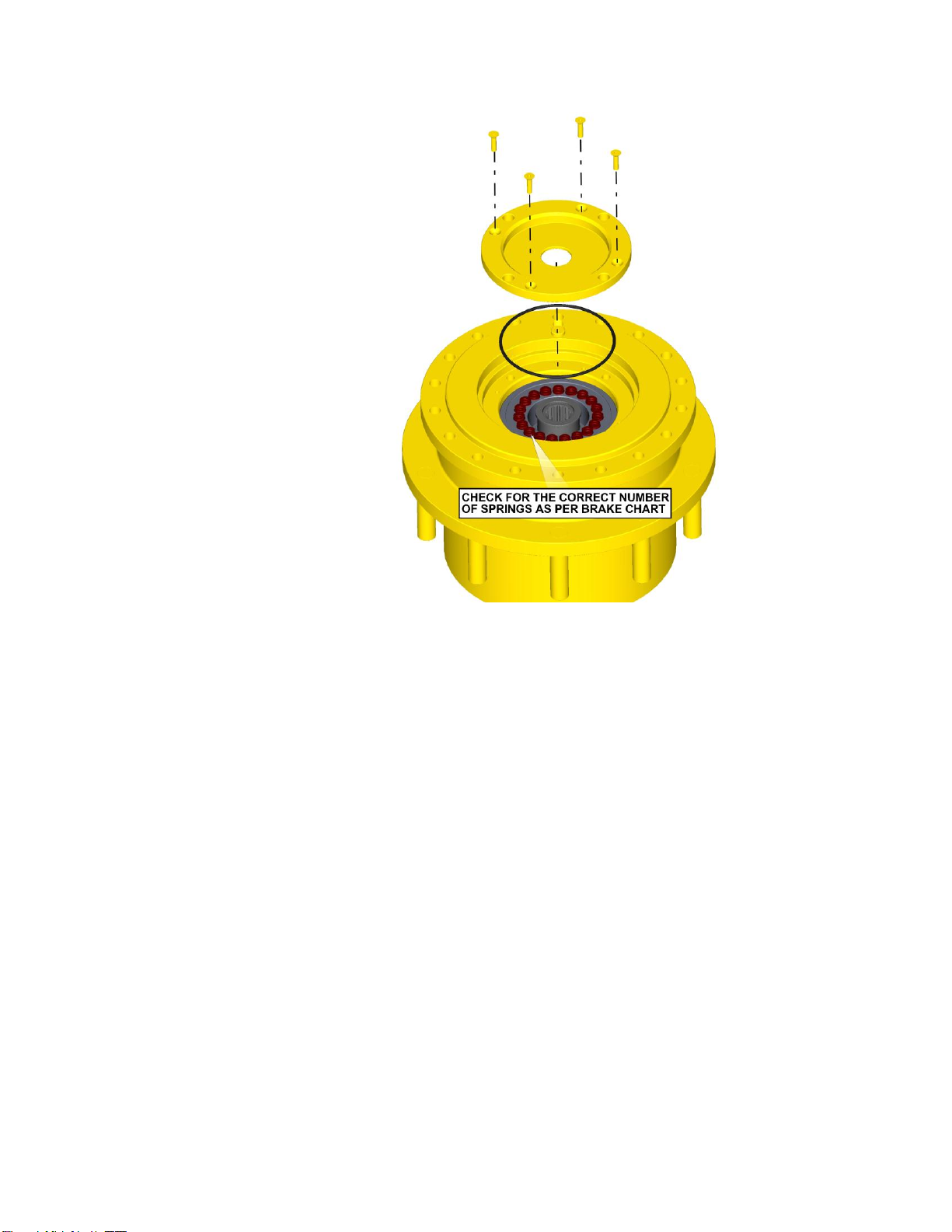

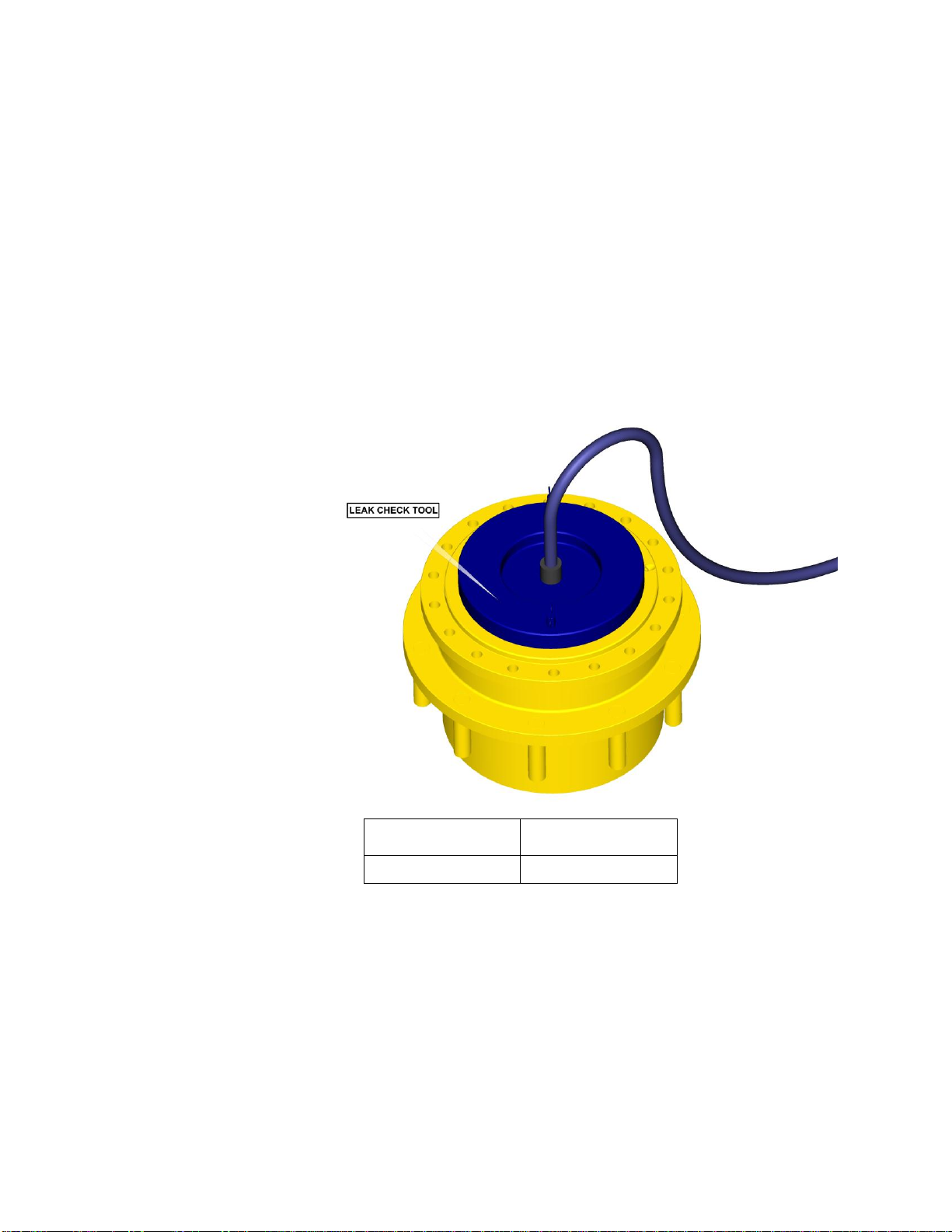

Record the release pressure. If the brake does not release within

limits shown in the brake chart on page 6, check to see if it has the

proper number of springs using the SPRING CHECKING

PROCEDURE. Increase to maximum pressure (refer to brake chart

on page 6) and hold at that pressure for one minute. If the brake

does not leak or lose pressure, the unit has passed the brake test. If

the brake loses pressure, attempt to repair the leak using the leak

repair procedure at end of this procedure.

While brake is still released, roll check the unit for one revolution of

the output member by rotating the tool. Bleed off pressure slowly

while rotating the ROLL TEST Tool.

Record the pressure at which the brake locks up. Using a clean rag,

wipe off excess fluid from around the brake port and install the pipe

plug.

Continued on Next Page