Safety Information

4 GA01297_002_A1 - 11/2014 - © Oerlikon Leybold Vacuum

0 Important Safety Information

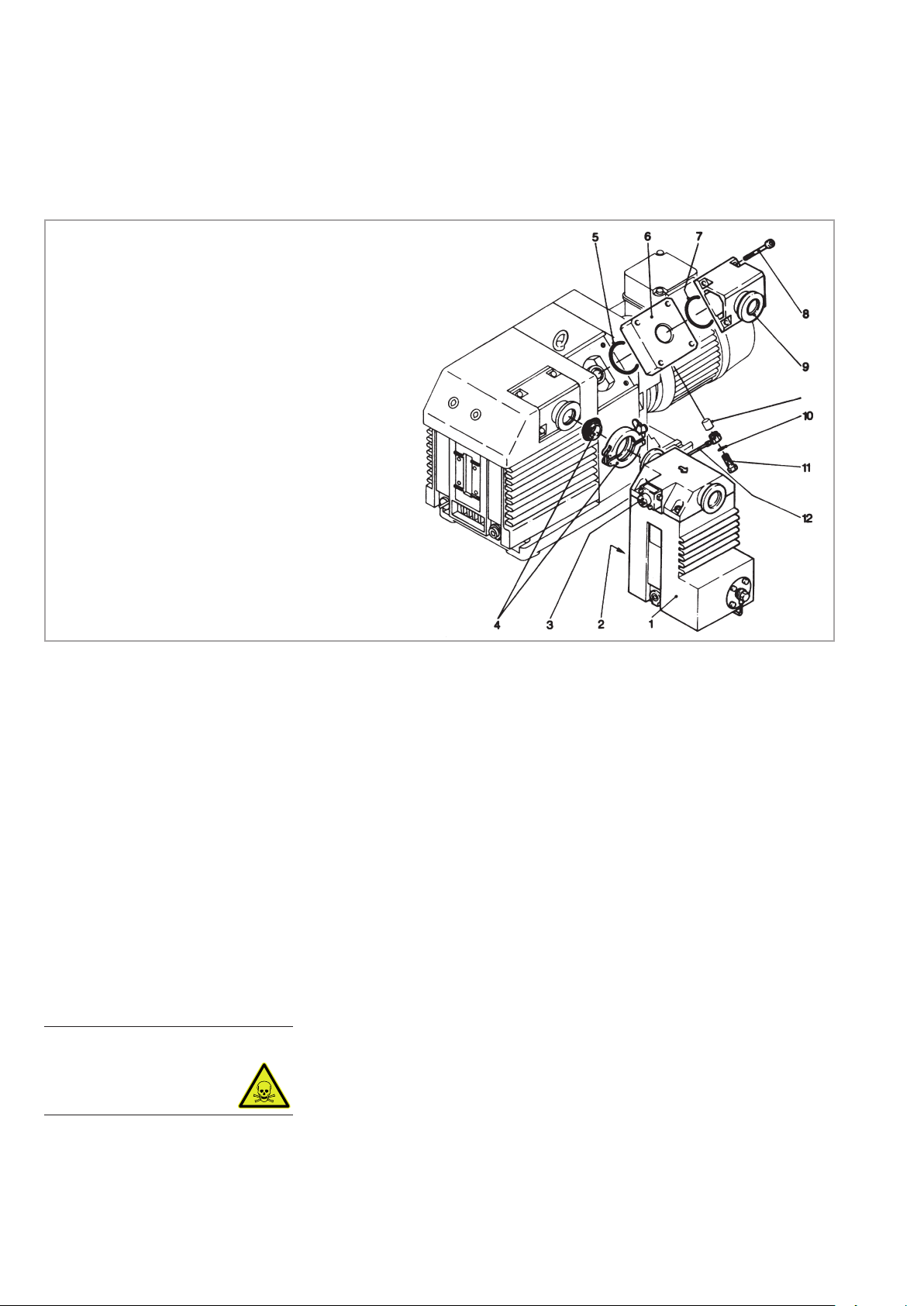

0.1 Hazards caused by materials and substances

1 Hazardous substances may escape from the filter, condensate or the

oil. Take suitable precautions (e. g. gloves, goggles or gas mask).

Observe all safety regulations.

2 When toxic gases or vapors are pumped, an exhaust line must be

fitted in accordance with the safety regulations relating to protection

against poisonous vapors.

3 Contaminated parts can be detrimental to health and environment.

Before beginning with any work, first find out whether any parts are

contaminated.

Adhere to the relevant regulations and take the necessary precautions

when handling contaminated parts; For example wear gloves, face

protection or breathing protection.

If there exists a potential hazard, the filter or the separator must be

decontaminated before starting with any maintenance work.

The filter pot may be as hot as 90 °C.

There is the danger of receiving burns.

Wear suitable protective clothing.

For professional decontamination we recommend our service.

4 The equipment must be packed in such a way, that it will not be dam-

aged during shipping and so that any contaminants are not released

from the package.

5 When disposing of used oil and spent filter and filter elements, please

observe the relevant environmental protection regulations.

6 The ARS can be operated with perfluoropolyether (PFPE) as lubricant.

When handling PFPE you should observe the following:

During thermal decomposition at temperatures over 290 °C toxic and

corrosive gases are released. When handling PFPE keep it away from

open fires. Do not smoke with PFPE on your fingers.

Touch the inner sections of the pumps only while wearing clean gloves,

and use clean tools;

do the necessary work in clean and dry rooms;

after having removed the pump from its packaging, start it up as

quickly as possible;

as cleaning agents solvents based on hydrofluorether compounds may

be used..

0.2 Risk of damaging the device

1 The filter element should be changed regularly, depending on the oper-

ating conditions.

Clogged filters will increase the pump’s temperature.

2 Only original filter elements guarantee the function of the pressure relief

valve.

DANGER

NOTICE