Issue 08.23 3www.oetiker.com

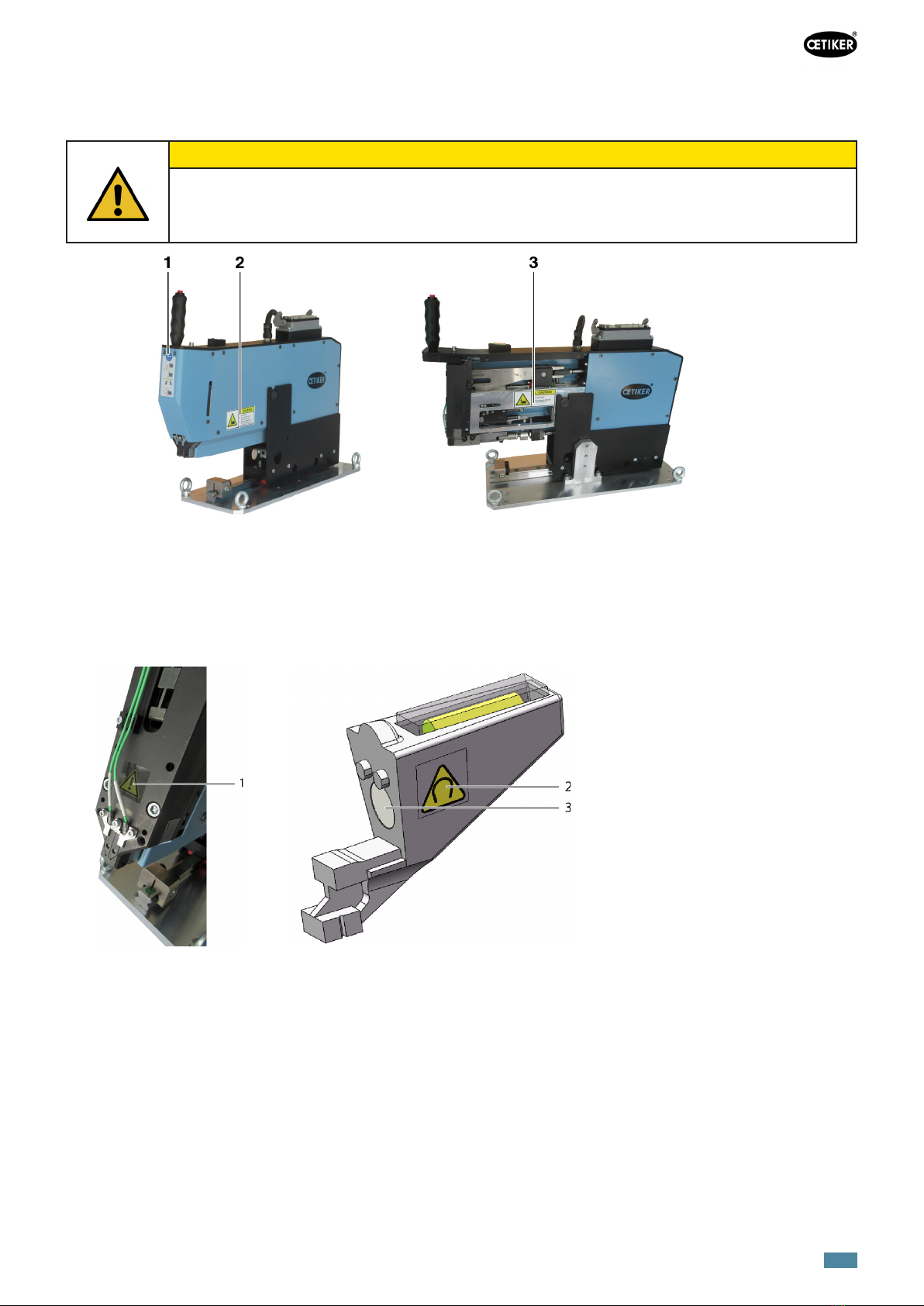

OETIKER FAST 3000

CONTENT

08906397

5.2 Crimping monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

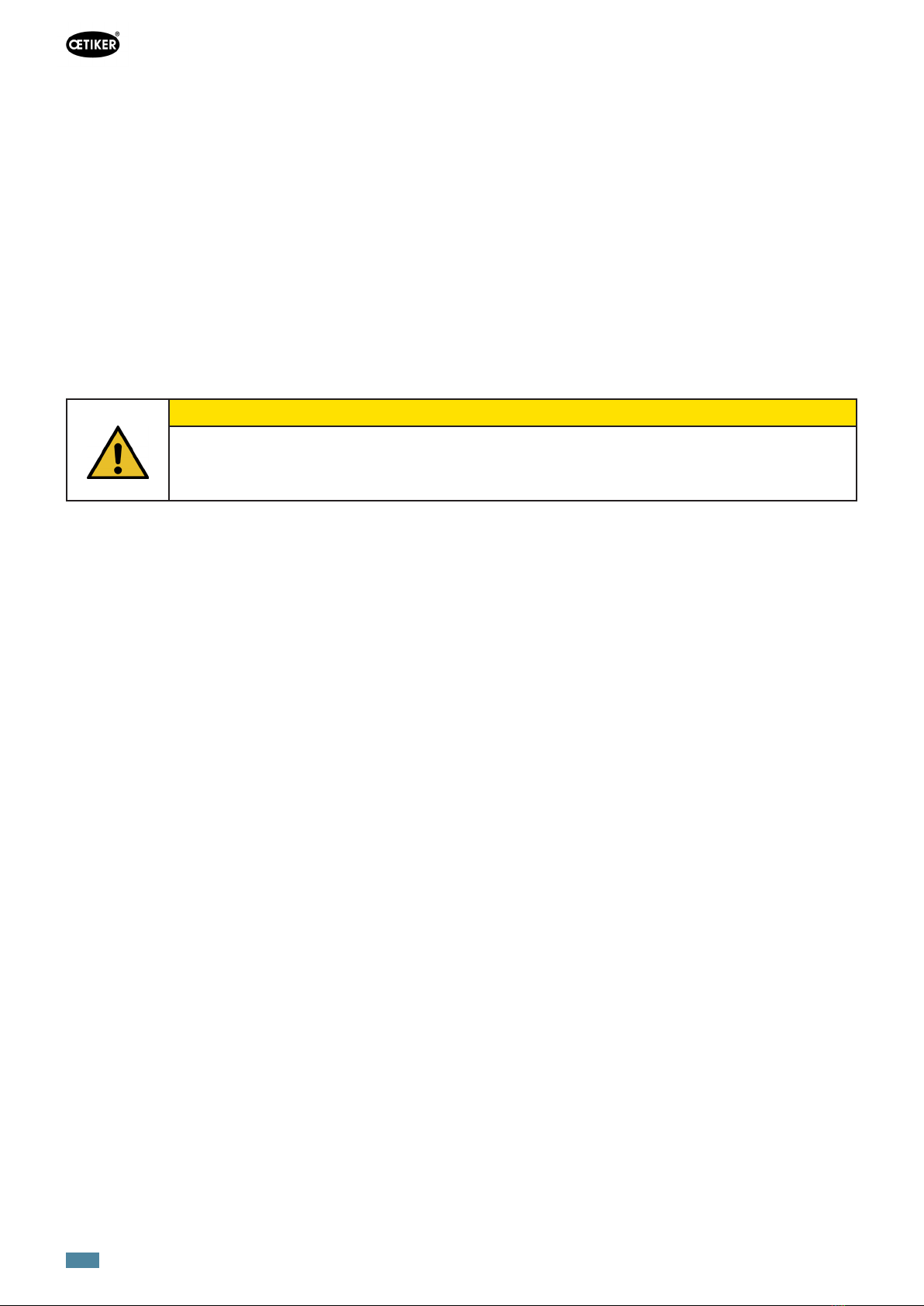

5.2.1 General information on the crimping force monitoring (CFM) . . . . . . . . . . . . . . . . . . 28

5.2.2 Mechanical design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.3 CFM: Typical OK force curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.4 CFM: Wear detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.5 CFM: Sample curves of crimping operations . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.3 Cut-off monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 Working with the FAST 3000 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

6.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.2 Connections to the control cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3 Cable connections to the crimping force monitoring devices . . . . . . . . . . . . . . . . . . . . . . . 49

6.4 Switching on the FAST3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.5 Correct positioning of the FAST 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.5.1 General instructions, positioning the FAST 3000 and WingGuard®clamp housing 52

6.5.2 Positioning the FAST 3000 installation tool using the alignment aid . . . . . . . . . . . . . . . 56

6.5.3 Dimensions for correctly positioning the FAST 3000 . . . . . . . . . . . . . . . . . . . . . . . 58

6.6 Normal operation (production) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.7 Laboratory mode (password-protected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.7.1 One-hand operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

6.7.2 Foot pedal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

6.8 Special operating modes (password-protected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.8.1 Deblocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.8.2 “Manual Drive” Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.8.3 Setting the force oset to zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.8.4 Verifying the pulling force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

6.8.5 Verifying the crimping force monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

6.8.6 Adjusting the crimping force monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.8.7 Changing the measurement program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

6.8.8 Loading new settings/measurement programs to the CFM units. . . . . . . . . . . . . . . . . 82

7 GUI (Graphical User Interface) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 84

7.1 Touch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2 Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

7.3 GUI layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.4 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.4.1 Welcome screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.4.2 Closure data (a password is necessary to change the values) . . . . . . . . . . . . . . . . . . 87

7.4.3 Operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

7.4.4 Free state pull force test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.4.5 I/O test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.4.6 Logbook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.4.7 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.4.8 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.4.9 Error list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.4.10 Access rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8 Assigning the IP address � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 115

8.1 Industrial communication X21/X22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.1.1 Setting the IP address for the EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.1.2 Setting the IP address for the Profinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.2 Touch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117