OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 3

Components #122-074 Fuse, 4 Amp, 5 mm × 20 mm (230 Volt Only)

#122-074-1 Fuse, 5 Amp, 5 mm × 20 mm (230 Volt Only)

#122-075 Fuse, 7 Amp, 5 mm × 20 mm (115 Volt Only)

#122-077 Fuse, 10 Amp, 5 mm × 20 mm (115 Volt Only)

#122-200 Hardened Blade Assemblies

#122-202 Container, Stainless Steel

#122-203 Container Lid

#122-204 Bottom Gasket

#122-209 Waring Blender®230 V with Exciter Gear and Pickup Cable

#122-210 Waring Blender®115 V with Exciter Gear and Pickup Cable

#152-34 Container, Glass (For Fracturing Fluids)

#164-42 Male Connector for Power Cable (230 Volt Only)

Optional:

#120-61 Spare Parts Kit, 115 Volt

#122-075 Fuse, 7 Amp, 5 mm × 20 mm (115 Volt Only), Qty: 4

#122-077 Fuse, 10 Amp, 5 mm × 20 mm (115 Volt Only), Qty: 4

#122-200 Blending Assembly / Square Drive, 1 qt., Qty: 12

#122-202 Stainless Steel Container, 1 qt.

#122-203 Container Lid, 1 qt.

#122-204 Bottom Gasket, Qty: 6

#120-61-1 Spare Parts Kit, 230 Volt

#122-074 Fuse, 4 Amp, 5 mm × 20 mm, Qty: 4

#122-074-1 Fuse, 5 Amp, 5 mm × 20 mm, Qty: 4

#122-200 Blending Assembly / Square Drive, 1 qt., Qty: 12

#122-202 Stainless Steel Container, 1 qt.

#122-203 Container Lid, 1 qt.

#122-204 Bottom Gasket, Qty: 6

- Hardened stainless steel mixing blades

- Stainless steel 1-liter mixing container

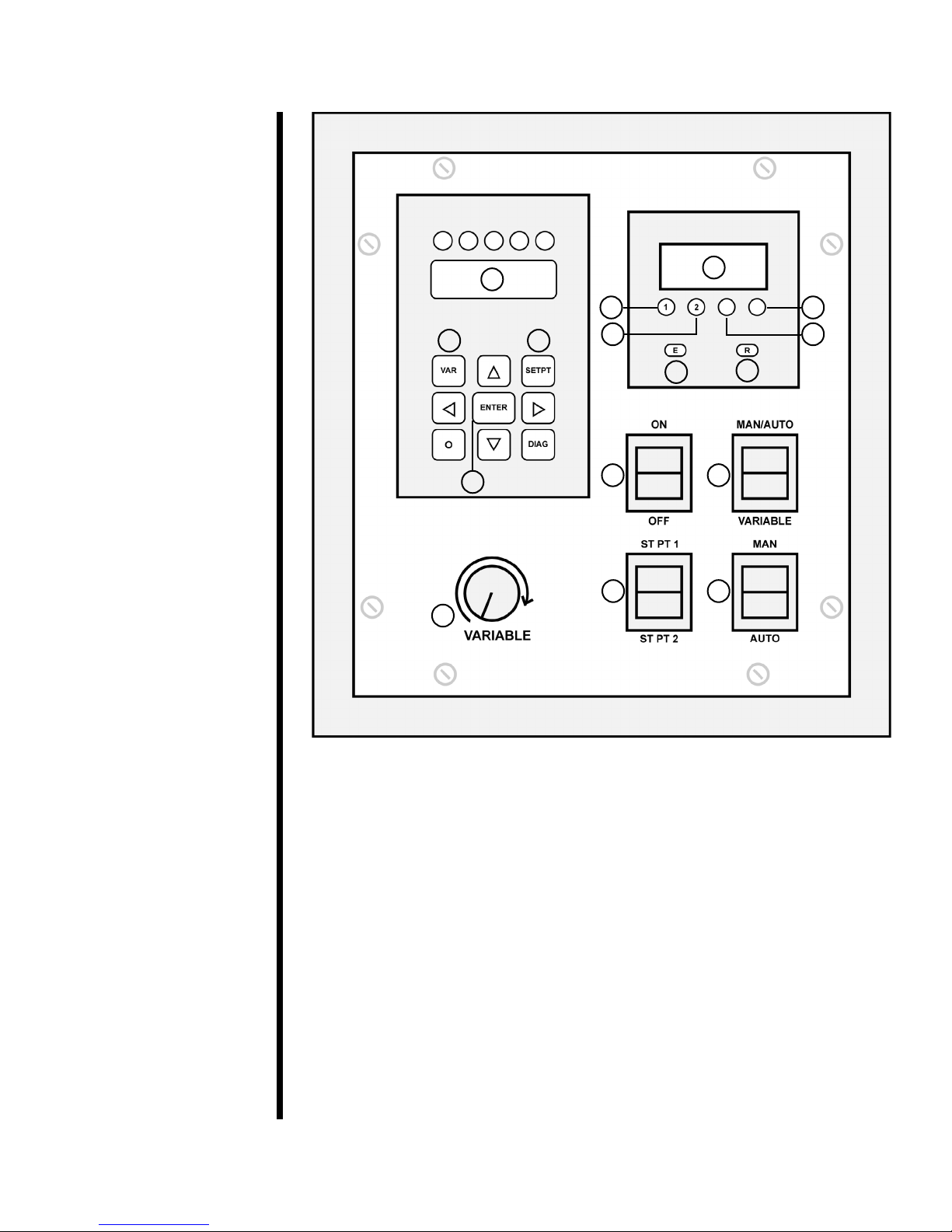

- Two preset mixing speeds and variable speed

- Maximum Speed for Cement Testing (120-60 / 120-60-1): 16,000 RPM

- Maximum Speed for Fracturing Fluid Testing (120-60-F / 120-60-1-F):

5,000 RPM

- Rotational speed is maintained at setpoint with microprocessor

- Timing relays automatically control mixing times at required RPM

- Digital instrumentation provides excellent readability

- Crated Size: 45" × 32" × 12" (114 × 81 × 31 cm)

- Crated Weight: Approximately 75 pounds (34.1 kg)

Specications