OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 2

The Model 60 Atmospheric Consistometer is designed to condition cement

slurries as specied within API Specication 10. Determination of rheological

properties and examination of free water content require that the cement

slurry be conditioned prior to testing. The OFITE Model 60 was specically

developed to perform these duties.

A cement slurry is prepared according to the procedure outlined in the

API Specication 10 and then placed in the slurry containers of the

Model 60 Atmospheric Consistometer. The slurry is stirred at 150 RPM

by an API-designed paddle assembly. The temperature is controlled by

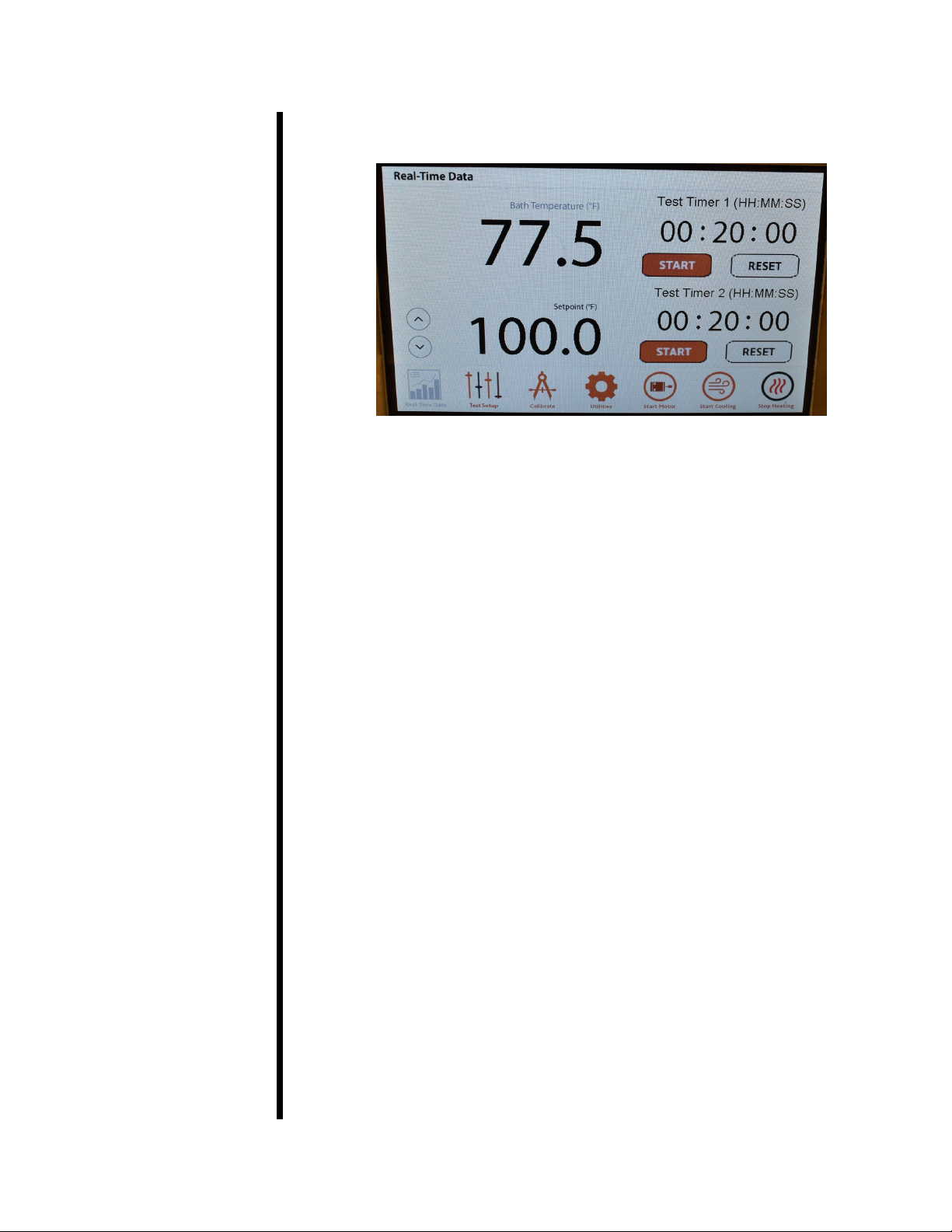

a microprocessor, which displays the process temperature via a digital

indicator. Consistency, measured in Bearden Units of Consistency, is

determined by measuring the deection of a calibrated spring. The spring is

connected to a pointer that rotates on a scale (numbered 1 through 10) on

the slurry container lid. This deection is created by the amount of torque that

the cement slurry exerts on the paddle, which is a function of the consistency

of the cement. The API denes 100 Bc as 2,080 g-cm of torque and each

number on the lid is a multiple of 10 (1 equals 10 Bc, 5 equals 50 Bc, and 10

equals 100 Bc).

- Redesigned frame and bearings reduces noise during operation

- Dual countdown timers that provide audible and visual notication for

each container

- Program and control temperature with multiple proles on the touch-

screen display

- Process temperature displayed on the touch screen

- Cooling coil for low temperature conditioning (optional chiller available)

- Maximum operating temperature of 200°F

- Unit is operated at atmospheric pressure

- Heat transfer uid is continuously circulated

- Heater wattage is 1,500

- Slurry container rotational speed is 150 RPM

- Dual container design

- Stainless steel temperature bath

- Deadweight calibration unit

- Size: 14.5" × 15.5" × 24.5" (37 × 39 × 62 cm)

- Weight: 95 lb (43.1 kg)

- Crated Size: 32" × 21" × 32" (81 × 53 × 81 cm)

- Crated Weight: 200 lb (90.7 kg)

- Water Supply for Cooling

- Water Drain

- 220 Volt, 50/60 Hz, 2.2 KVA Power Source

- 120 Volt, 50/60 Hz, 4.4 KVA Power Source

Intro

Description

Features

Requirements