Patent No. 6,766,028 - OFI Testing Equipment, Inc.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 4

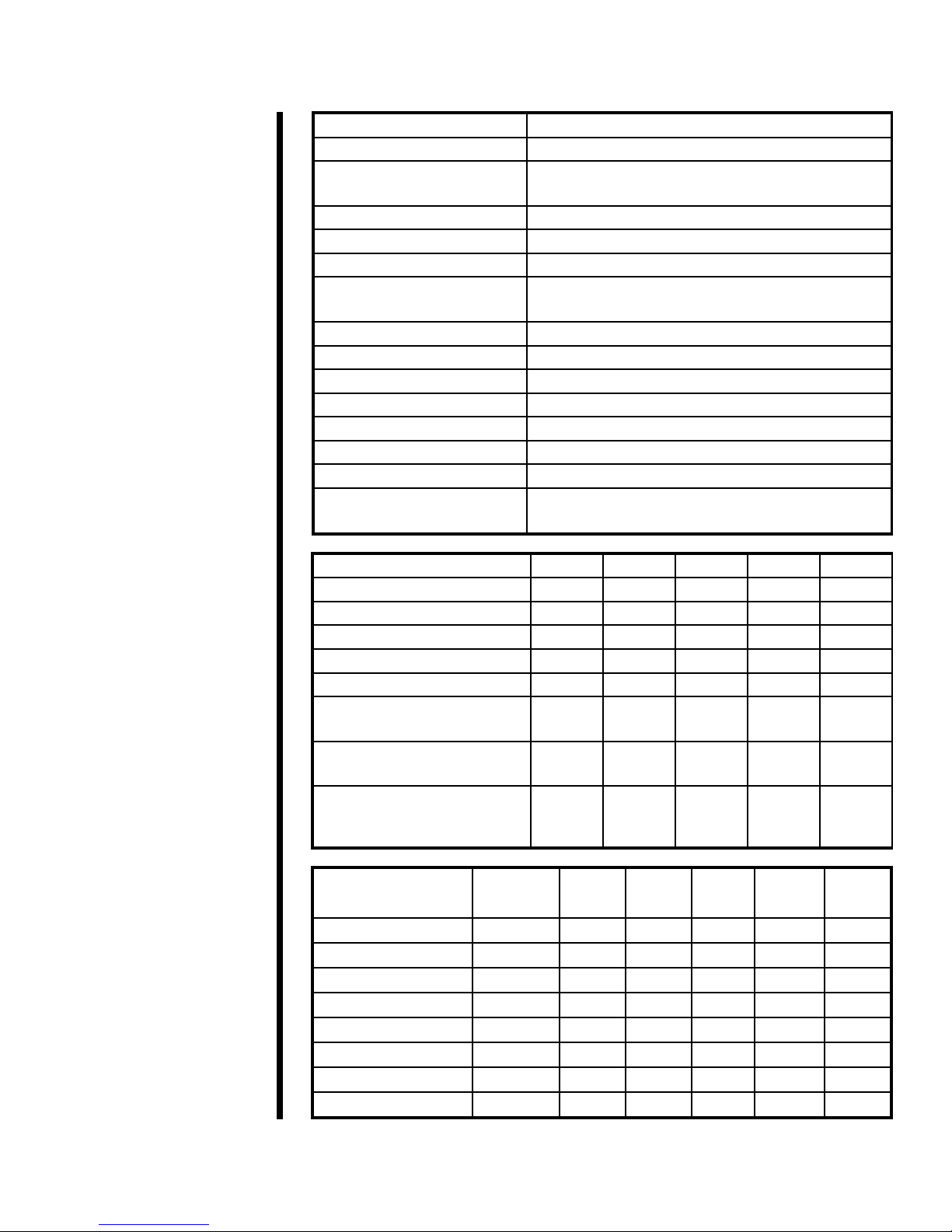

Specications Instrument Geometry True Couette Coaxial Cylinder

Motor Technology Stepper

Motor Speeds (RPM) 12 Fixed Speeds (600, 300, 200, 100, 60, 30, 20,

10, 6, 3, 2, and 1); Variable speed range .006 - 1000

Speed Accuracy (RPM) .001

Shear Rate Range (sec-1).01 - 1,700

Readout Digital

Heat Cup Stainless Steel, 150 Watts, Maximum

Recommended Temp: 190°F (88°C)

Temperature Measurement Type “J” Thermocouple

Automatic Tests API Cementing and Mud Rheologies

Power Requirements 97 - 250 Volts AC, 200 Watts, 50/60 Hz

Weight (kg) 8.6

Dimensions (cm) 44 × 38 × 24

Shipping Weight (kg) 16

Shipping Dimensions (cm) 56 × 38 × 24

Computer Requirements DB-9 Serial Port, Windows 2000 or newer.

Recommended screen resolution 1024 × 768 pixels.

Rotor - Bob R1B1 R1B2 R1B3 R1B4 R1B5

Rotor Radius, RR, (cm) 1.8415 1.8415 1.8415 1.8415 1.8415

Bob Radius, RB, (cm) 1.7245 1.2276 0.8622 0.8622 1.5987

Bob Height, L, (cm) 3.8 3.8 3.8 1.9 3.8

Shear Gap, (cm) 0.117 0.6139 0.9793 0.9793 0.2428

R Ratio, RB/RR 0.9365 0.666 0.468 0.468 0.8681

Shear Rate Constant kR(sec-1

per RPM) 1.7023 0.377 0.2682 0.2682 0.8503

Shear Stress Constant for

Effective Bob Surface kS(cm-3)0.01323 0.02610 0.05290 0.10600 0.01541

Overall Instrument Constant,

K, with Standard F1.0 Spring,

ŋ=KfƟ/N

300 2,672 7,620 15,200 349

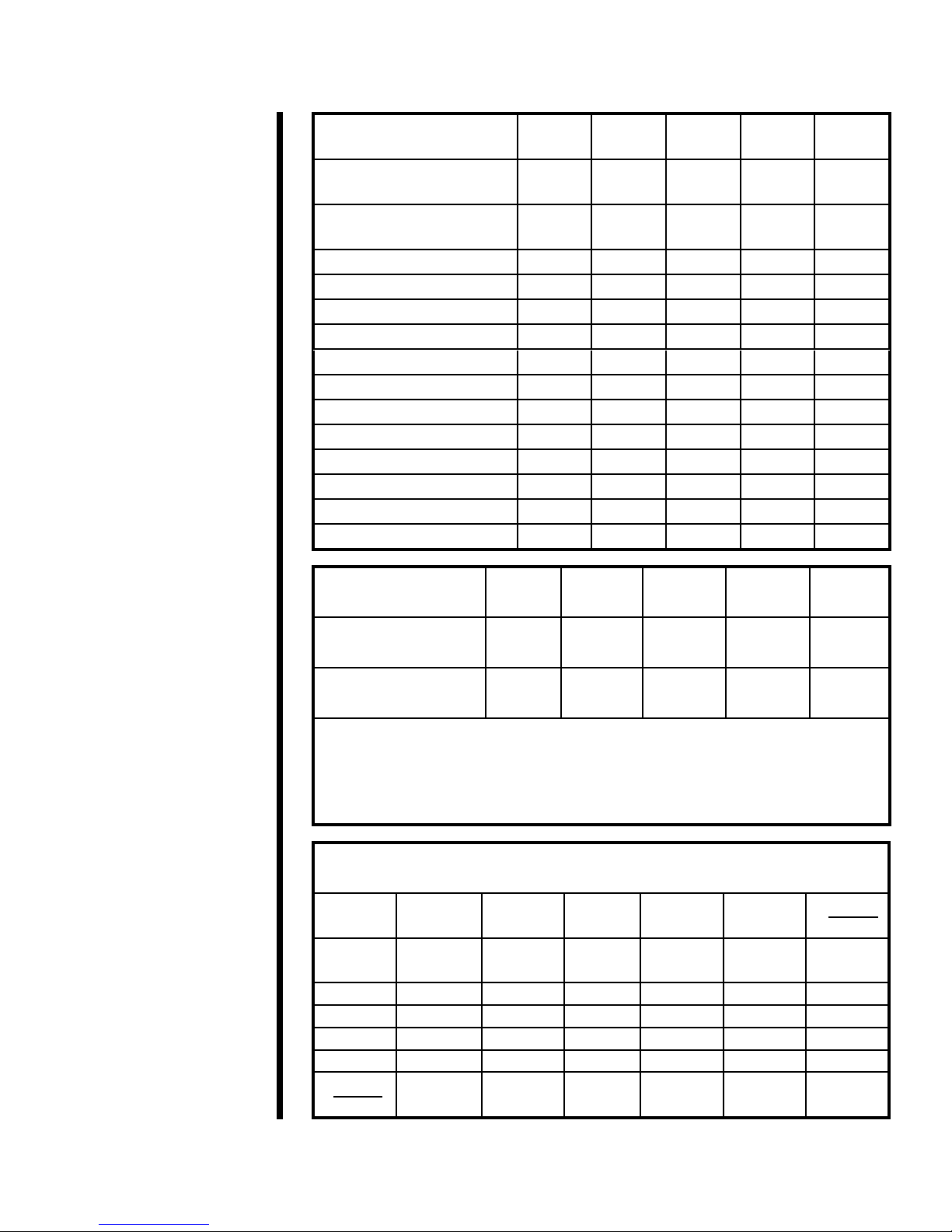

Max. Shear Stress,

SSMAX, (Dyne / cm2)

Constant

kT

R1B1 R1B2 R1B3 R1B4 R1B5

F 0.2 (Green) 77.2 330 651 1,320 2,644 384

F 0.5 (Yellow) 193 840 1,657 3,359 6,730 977

F 1.0 (Blue) 386 1,680 3,314 6,717 13,460 1,955

F 2.0 (Red) 772 3,360 6,629 13,435 26,921 3,910

F 3.0 (Purple) 1,158 5,040 9,943 20,152 40,381 5,865

F 4.0 (White) 1,544 6,720 13,257 26,870 53,841 7,819

F 5.0 (Black) 1,930 840 16,571 33,587 67,302 9,774

F 10.0 (Orange) 3,860 16,800 33,143 67,175 134,603 19,548