OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 1

Intro..................................................................................................2

Description......................................................................................2

Features...........................................................................................2

Specications .................................................................................3

Components ...................................................................................3

Safety...............................................................................................5

Quick Start ......................................................................................6

Setup................................................................................................7

Hardware ....................................................................................7

Software......................................................................................8

Software ........................................................................................10

Temperature Prole Builder ......................................................14

Operation ..................................................................................15

Calibration Archives ..................................................................17

Operation ......................................................................................19

Cell Cap Assembly....................................................................19

SGSM Drag Check ...................................................................27

Preparing the Test Cell..............................................................28

Connecting the Cell...................................................................29

Starting the Test........................................................................31

Stopping the Test ......................................................................32

Evaluating Test Data.................................................................33

Removing the Test Cell.............................................................34

Maintenance .................................................................................35

Disassembling and Cleaning the Test Cell................................35

Changing a Fuse.......................................................................41

Appendix ......................................................................................42

Filling The Cell ..........................................................................42

Magnet Positioning ...................................................................43

Calibration - Old Style ...............................................................44

SGSM Cell Cap Assembly ........................................................45

Calibration - New Style .............................................................49

Maintenance Schedule .............................................................51

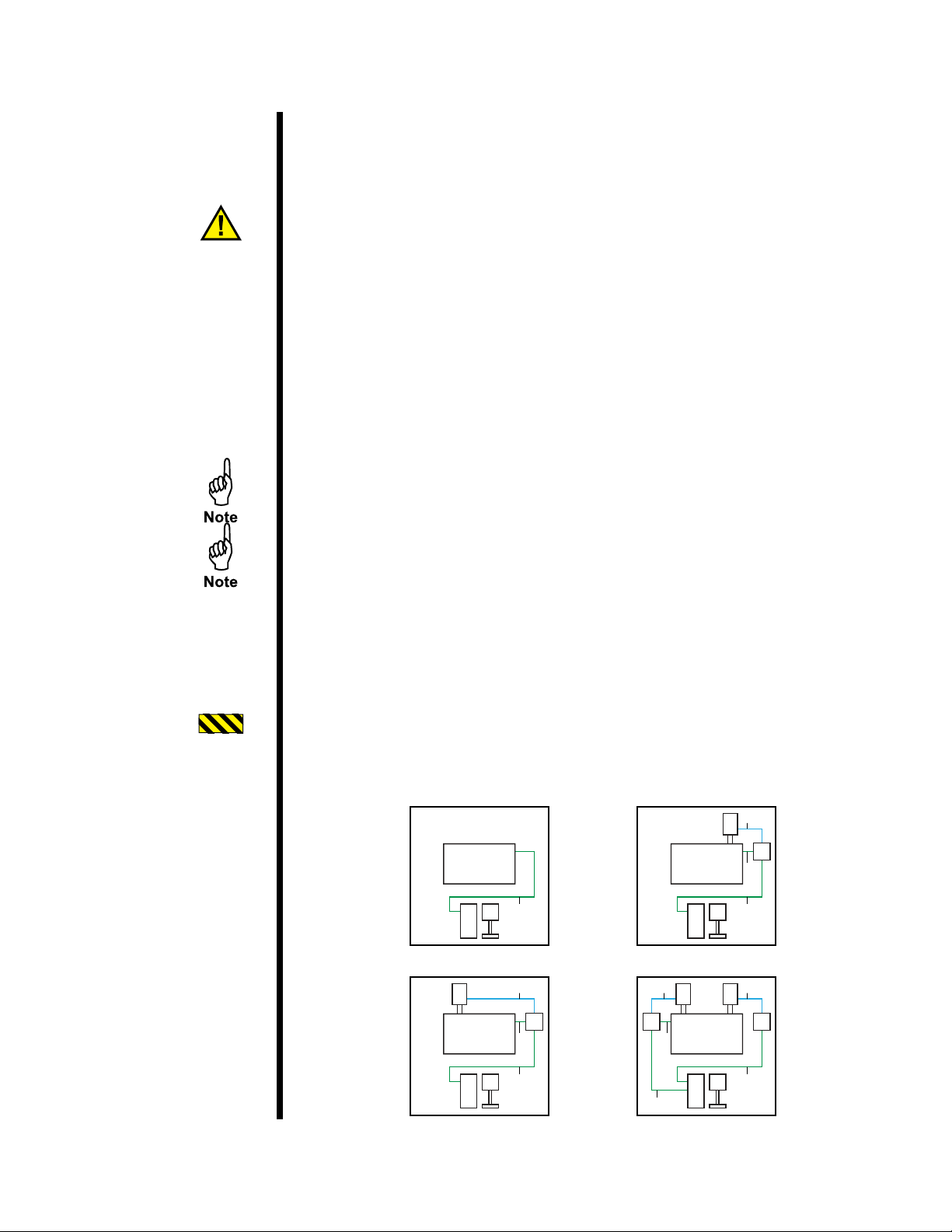

Multiple Instruments..................................................................52

Manual Temperature Control ...................................................53

Electrical System Grounding.....................................................56

Troubleshooting.........................................................................57

Diagrams - Drive Assembly.......................................................58

Diagrams - High Pressure Cell Assembly.................................59

Diagrams - Low Pressure Cell Assembly..................................60

Warranty and Return Policy ........................................................61

Table of

Contents