Copyright 2001 OFSFitel

All Rights Reserved

Printed in U.S.A.

Table of Contents

1. General ................................................................................................................................. 1

1.1 LC™Jumper Connectors................................................................................................. 1

1.2 Epoxy Consumables......................................................................................................... 1

1.3 Epoxy Tool and Upgrade Kits........................................................................................... 1

1.4 Ordering Information........................................................................................................ 2

2. Safety Precautions................................................................................................................. 2

3. Oven Preparation .................................................................................................................. 2

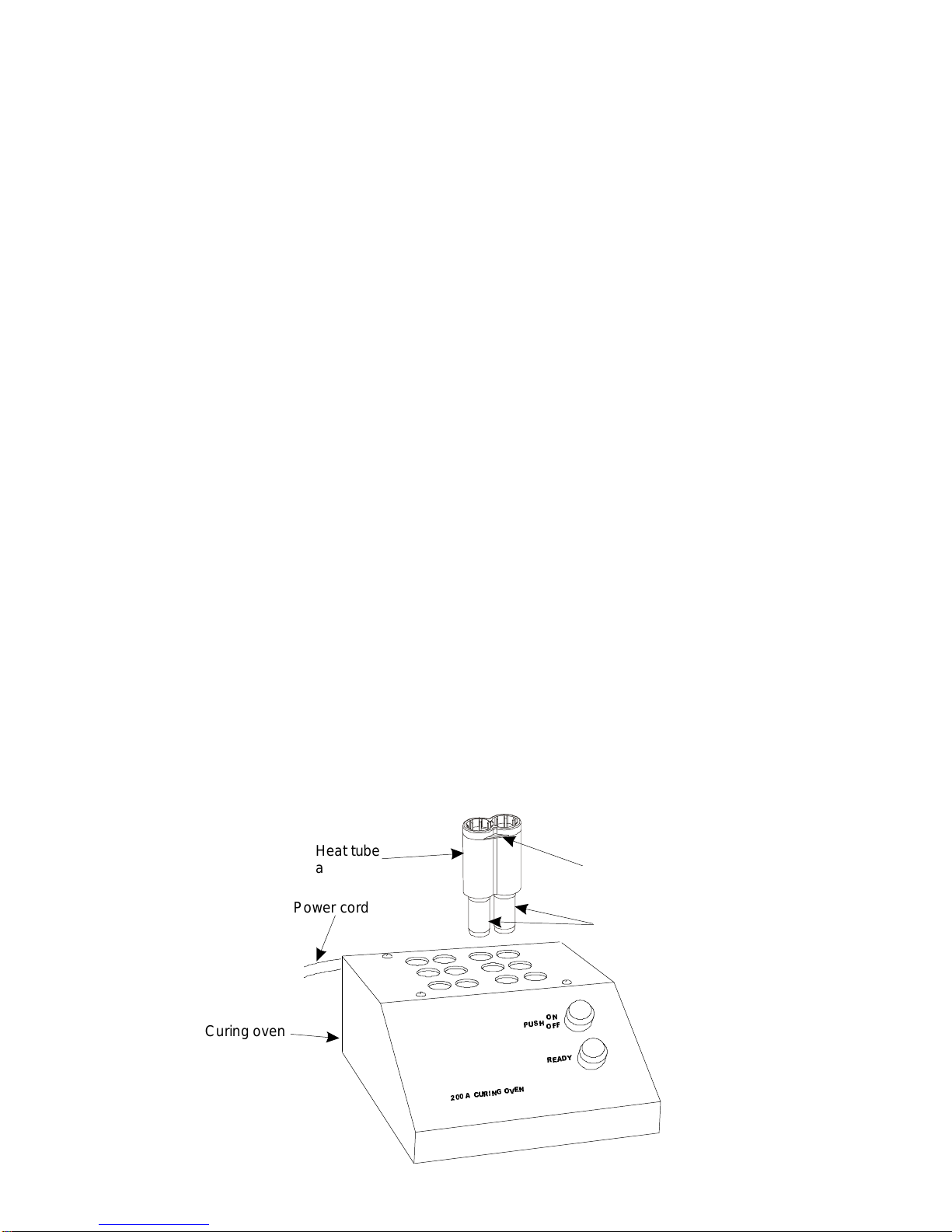

3.1 Set Up Curing Oven.........................................................................................................2

4. Cord Preparation ................................................................................................................... 3

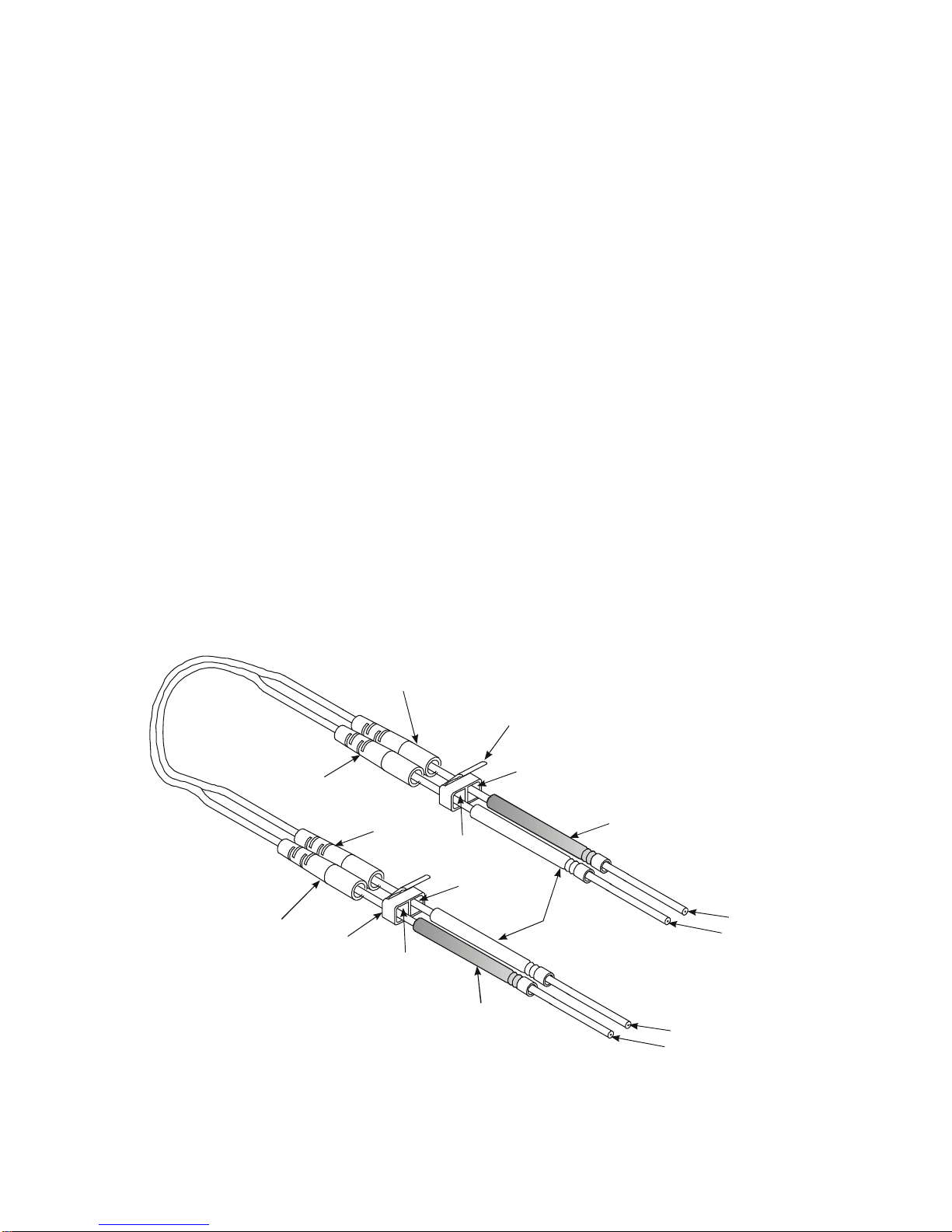

4.1 Assemble Connector Components.................................................................................... 3

4.1.1 Simplex Applications on a Simplex Cord.................................................................... 3

4.1.2 Singlemode Simplex Applications on a Duplex Cord.................................................. 3

4.1.3a Duplex Applications on a Duplex Cord (with Regular Duplex Yoke).......................... 4

4.1.3b Duplex Applications on a Duplex Cord (with Replaceable Duplex Yoke)................... 5

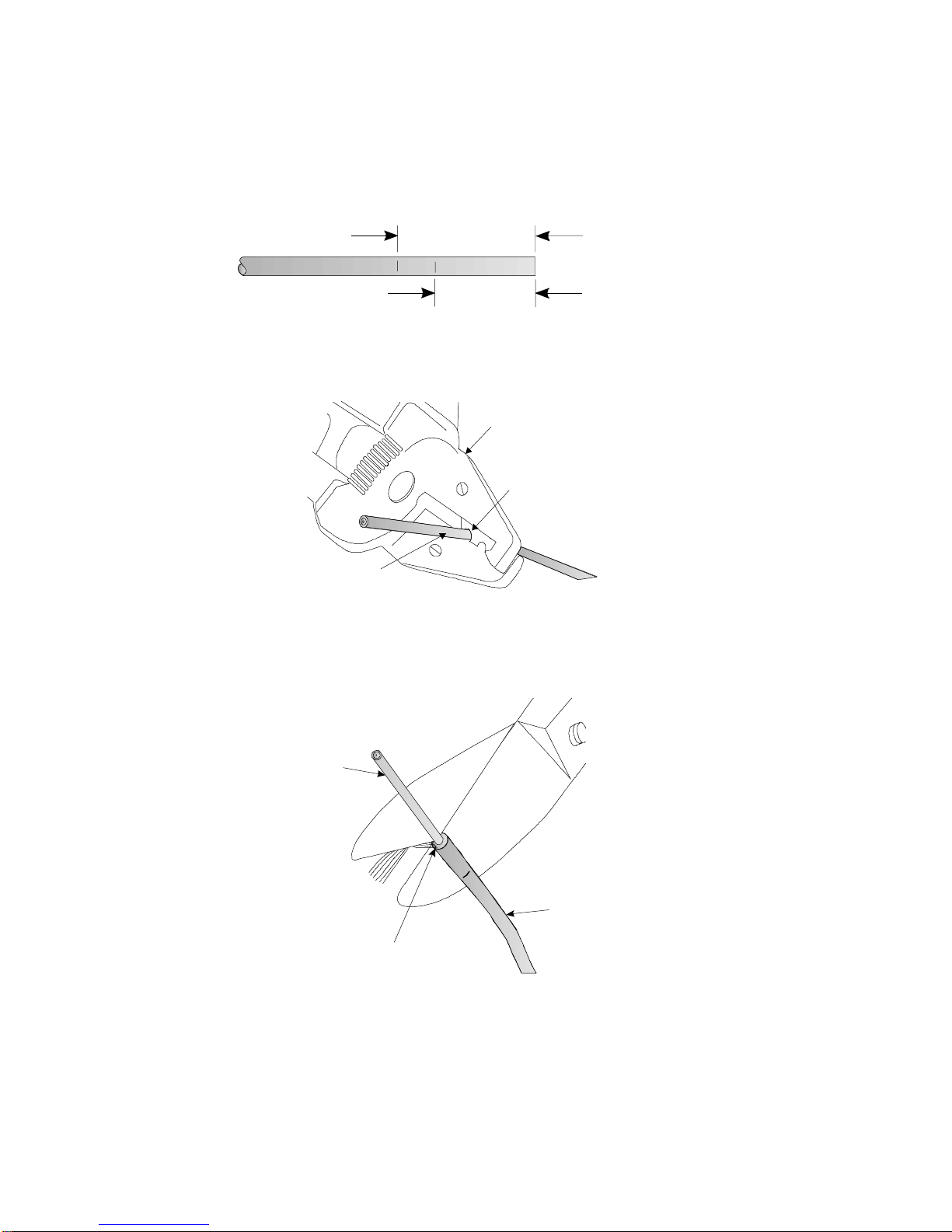

4.2 Remove Outer Jacket and Trim Strengthening Yarn......................................................... 6

4.3 Remove Buffer and Fiber Coating.................................................................................... 7

4.4 Clean Stripped Fiber ........................................................................................................ 8

5. Epoxy Preparation................................................................................................................. 9

6. Connector Installation.......................................................................................................... 10

6.1 Prepare the Connector ................................................................................................... 10

6.2 Apply Epoxy................................................................................................................... 10

6.3 Insert Fiber..................................................................................................................... 11

6.4 Install Crimp Sleeve....................................................................................................... 12

6.5 Cure Connector Assemblies........................................................................................... 13

6.6 Cool Connector Assemblies............................................................................................ 13

6.7 Score the Fiber............................................................................................................... 13

6.8 Polish Fiber EndMultimode and Singlemode................................................................ 14

6.9 Repair Polishing Only...................................................................................................... 16

6.10 Final Assembly.............................................................................................................. 16

6.10.1 Simplex Connectors............................................................................................... 16

6.10.2a Duplex Connectors (with Regular Duplex Yoke) ................................................... 16

6.10.2b Duplex Connectors (with Replaceable Duplex Yoke)............................................ 17

7. Fiber Inspection and Ferrule Endface Geometry.................................................................. 18

7.1 Fiber Inspection............................................................................................................... 18

7.2 Ferrule Endface Geometry.............................................................................................. 19

8. Cleaning Instructions ........................................................................................................... 20

8.1 LC Connector................................................................................................................. 20

8.2 Adapter .......................................................................................................................... 20

9. Tuning Instructions .............................................................................................................. 21

9.1 General Information ....................................................................................................... 21

9.1.1 Tuning Index Tool.................................................................................................... 21

9.1.2 Tuning Wrench........................................................................................................ 21

9.1.3 Singlemode Offset Tuning Jumper........................................................................... 22

9.1.4 Hardcase with Foam Insert....................................................................................... 22

9.1.5 Instruction Sheet...................................................................................................... 22

9.2 Safety Information.......................................................................................................... 22

9.3 Tuning Procedure........................................................................................................... 23

10. Mount Adapter................................................................................................................... 27

11. Ordering Information.......................................................................................................... 28

12. Assistance Information....................................................................................................... 31