User`s manual RA-915+

Contents

Introduction ....................................................................................................... 2

Application ........................................................................................................ 4

Design and operation of the analyzer .............................................................. 6

Physical foundation and principle of operation ...................................... 6

Design of analyzer ................................................................................. 7

Appearance and functional controls ................................................................. 8

Front panel view ..................................................................................... 8

Back panel view ................................................................................... 10

Right panel view .................................................................................... 11

Left panel view ....................................................................................... 11

Upper panel view .................................................................................. 12

Pre-operational procedures ............................................................................ 12

Operation with the display unit ....................................................................... 15

Description of the MAIN MENU ........................................................... 15

SETTINGS ................................................................................. 15

TEST .......................................................................................... 17

ON STREAM ............................................................................. 19

ON-TIME .................................................................................... 21

HIGH CONCENTRATIONS ........................................................ 24

Operation with a PC ....................................................................................... 24

Serviceability check-up ........................................................................ 25

Measuring procedure ........................................................................... 25

Maintenance ................................................................................................... 25

Charging the battery ............................................................................ 26

Changing of the dust filter .................................................................... 26

Changing of the absorption filter .......................................................... 26

Changing the Pre-filter ......................................................................... 27

Preventive maintenance ....................................................................... 27

Appendix 1 ...................................................................................................... 28

Troubleshooting .................................................................................... 28

Appendix 2 ...................................................................................................... 29

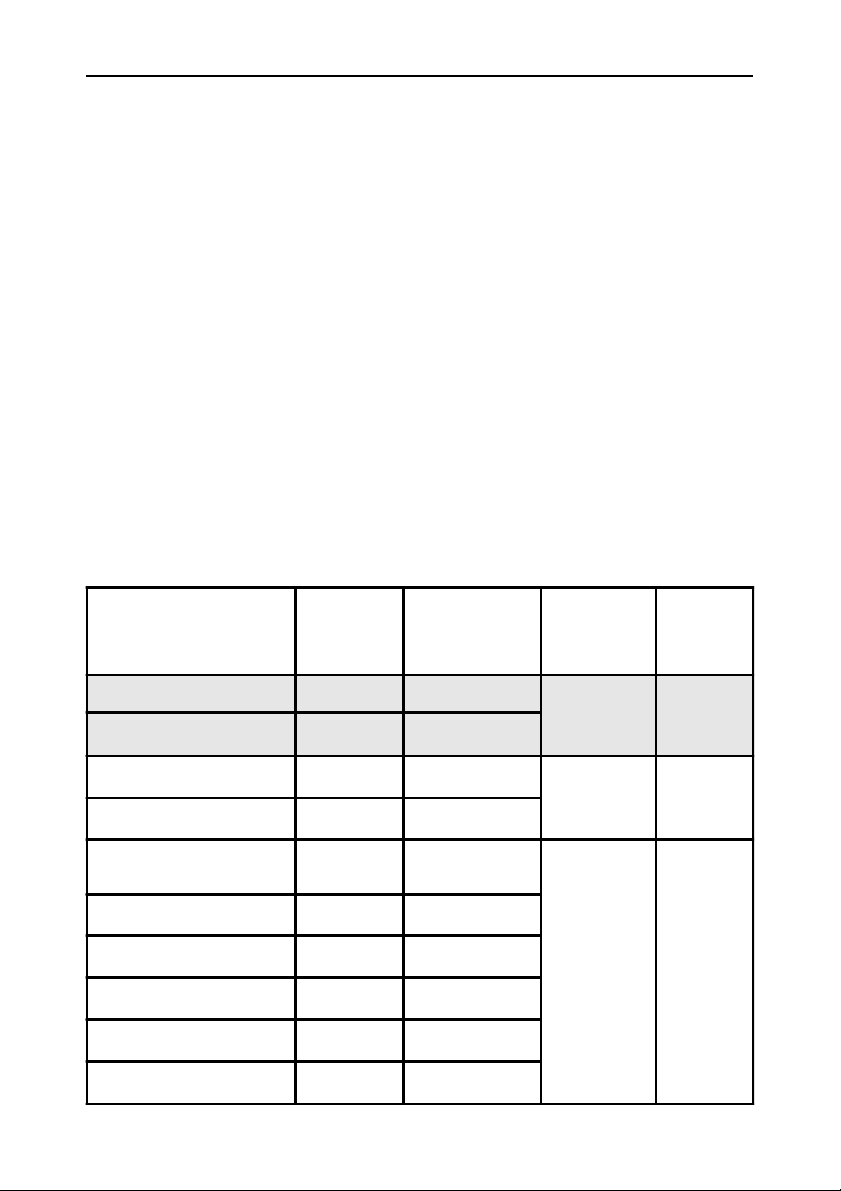

Values of the test number Sk as a function of the temperature of the

test cell ................................................................................................ 29