-9-

○Pick uping Screws

・Pick up the screws at the stopper with the screwdriver on the robot.

Use the bit guide to put the screwdriver down vertically into the screwhead's

slots.

・When the screwdriver is inserted into the screwhead slots, be careful that

no contact is made with the escaper or that the screw is not struck forcefully.

Using excessive force may alter the position of the escaper or cause damage

to the machine.

・Use a driver bit which corresponds with the screw's diameter.

・Read the screw pick uping robot manual for more details on how to use the

robot with this machine.

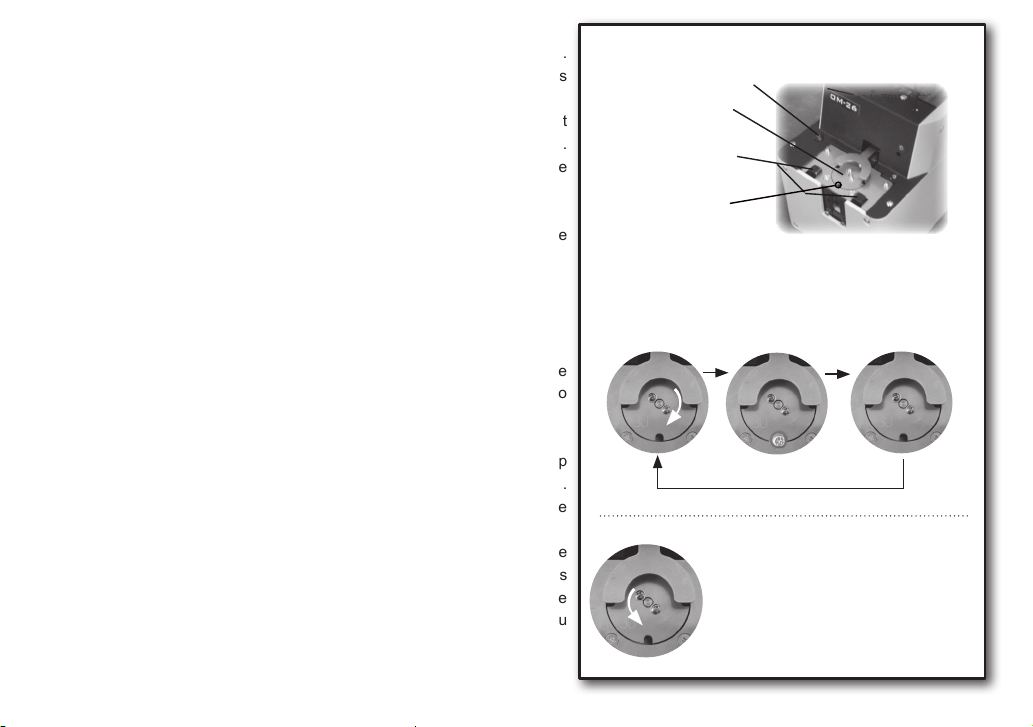

○Action of the escaper

・The escaper rotates 90° clockwise--> stops for about 0.6 seconds

--> and rotates again 90° clockwise.

When a screw is caught in the escaper and the notch position is altered, the

escaper automatically rotates to the left, as a reference point run, in order to

adjust the notch position and then returns to the right rotation.

・This machine continues its operation when no screw is found at the screw

pick up spot. The machine continues operating with a screw at the pick up

spot but will stop, after a certain lapse of time, if the screw is not picked up.

After the screw is picked up, the machine starts operating again. This time

lapse can be varied by adjusting the timer.

・When no screw is found at the pick up site after a certain lapse of time, the

rail vibration increases. (The vibration sound, also, increases however, this

is not a problem.) If no screw is still not found at the pick up site, then the

machine stops operating. At this time the escaper keeps rotating. When you

want to start operation again, turn the power switch OFF and ON again.

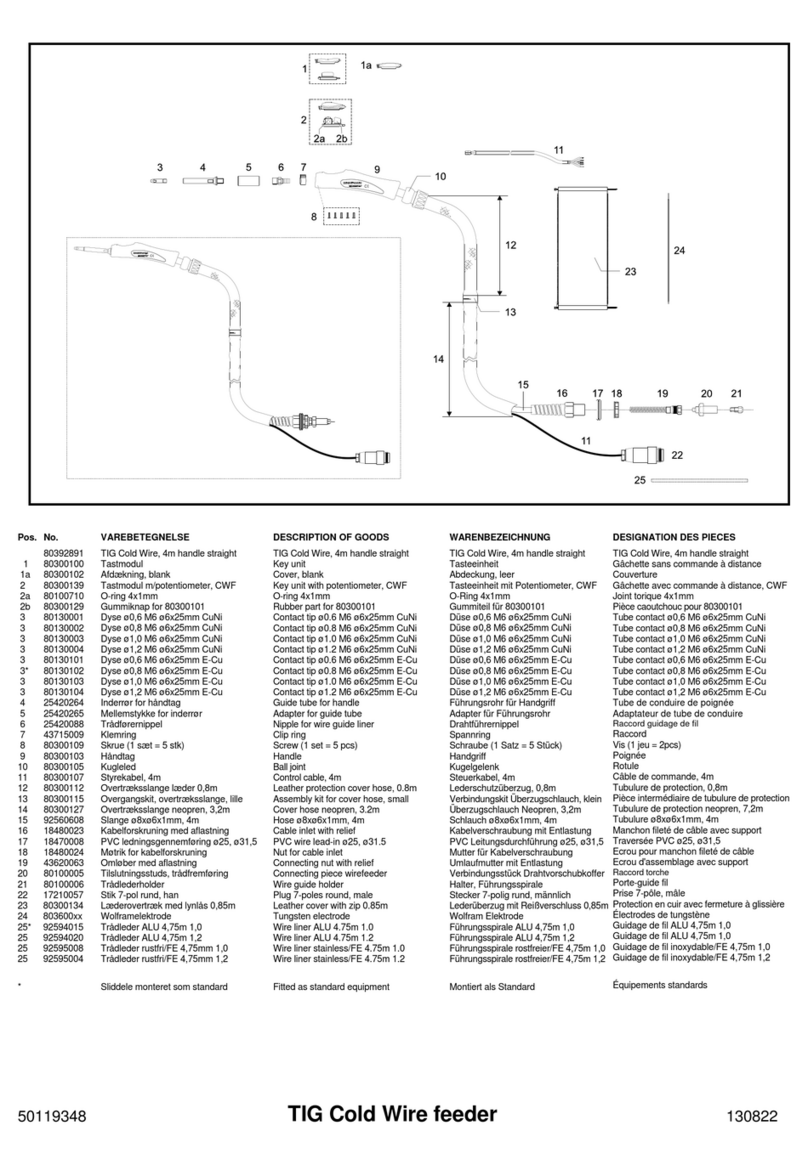

Escaper ねじ取出し部

Sensor

Accepting a screw.

LED screw indicator is

OFF

The screw is carried to

the pick up site.

LED screw indicator is

ON

Pick uping the screw

at the pick up site.

LED screw indicator is

OFF

The rotation of the escaper, in the opposite

direction, is a reference point run of the escaper

motor.

The rotation of the escaper, in the opposite

direction, occurs when the power is turned on and

the starting point of the escaper is not alligned

with the reference point of the escaper motor.

During regular operation, as in the gure above,

the escaper rotates clockwise.

(Reference)

LED screw indicator

○Action of the escaper

Screw pick up spot