PEC Flaw Detector PE4332 Operation Manual

+7(812) 385-54-28

info@oktanta-ndt.ru 2

Contents

PURPOSE ........................................................................................................................................... 3

PRINCIPLE OF OPERATION.................................................................................................................. 5

TECHNICAL CHARACTERISTICS ............................................................................................................ 6

PEC FLAW DETECTOR APPEARANCE .................................................................................................. 7

Device ............................................................................................................................................ 7

Sensor ...........................................................................................................................................10

DEVICE MENU ...................................................................................................................................12

Scanning start/stop/continuation menu. .................................................................................13

Calibration ..............................................................................................................................15

Grid ........................................................................................................................................16

Test item parameters ..............................................................................................................24

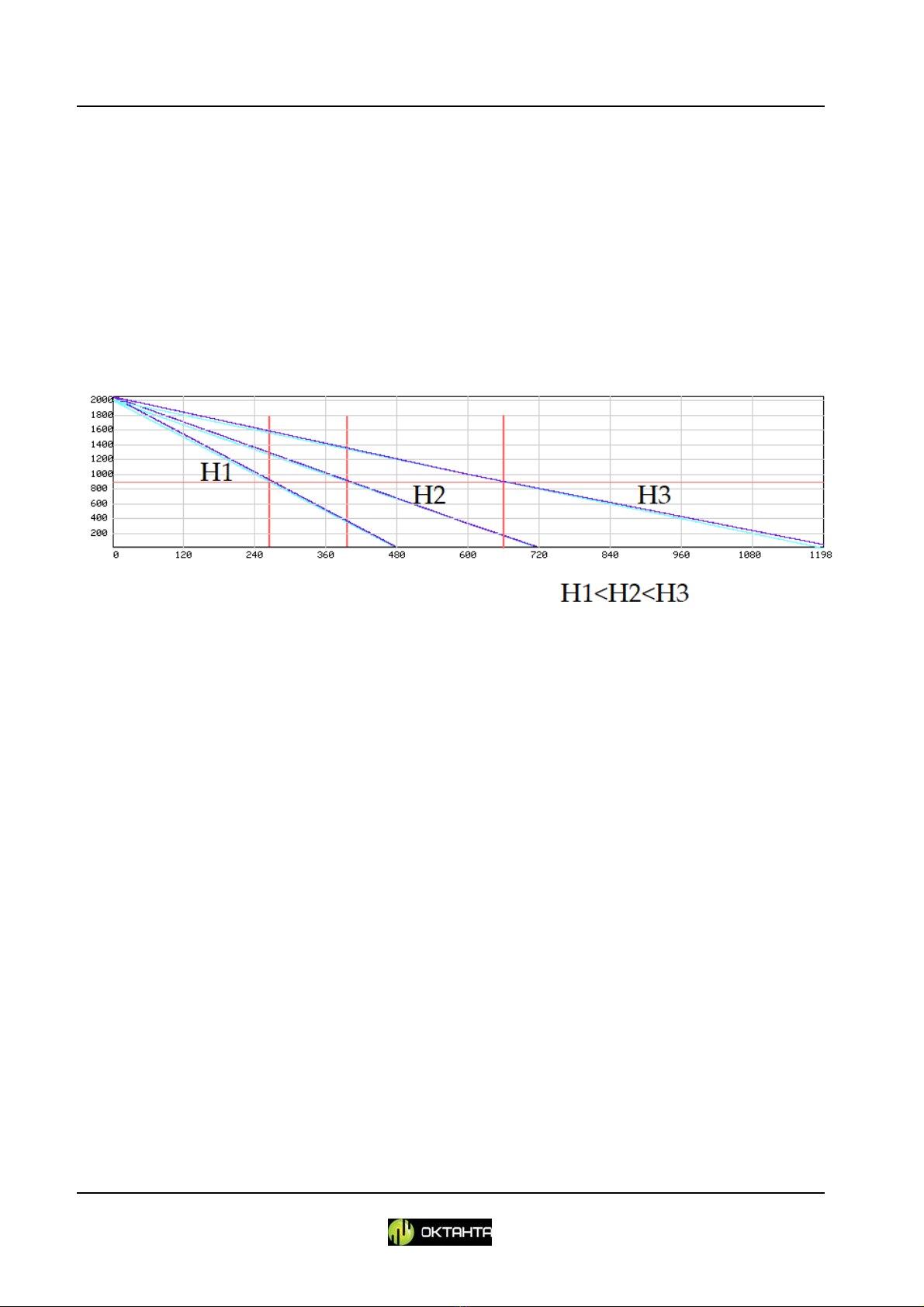

Diagrams ................................................................................................................................31

Insulation thickness ................................................................................................................34

Thresholds ..............................................................................................................................35

Averaging................................................................................................................................37

Main menu .............................................................................................................................38

DEVICE OPERATION ..........................................................................................................................44

Sensor Selection............................................................................................................................44

Thickness Measurement ...............................................................................................................48

Scan mode ....................................................................................................................................50

Data Transfer ................................................................................................................................58

MAINTENANCE .................................................................................................................................58

Battery Replacement ....................................................................................................................58

Sensor Replacement .....................................................................................................................59

Encoder Installation and Removal .................................................................................................60

TRANSPORTATION AND STORAGE .....................................................................................................61

SCOPE OF SUPPLY .............................................................................................................................61

MANUFACTURER WARRANTY ...........................................................................................................62

INFORMATION ABOUT REPAIR ..........................................................................................................63