EM1401 / EM1401 UT EMA Thickness Gauge. Operation Manual.

+7(812) 385-54-28

info@oktanta-ndt.ru 2

CONTENTS

CONTENTS ................................................................................................................................ 2

INTENDED USE..................................................................................................................... 4

PRINCIPLE OF OPERATION ........................................................................................... 4

TECHNICAL SPECIFICATIONS .................................................................................... 5

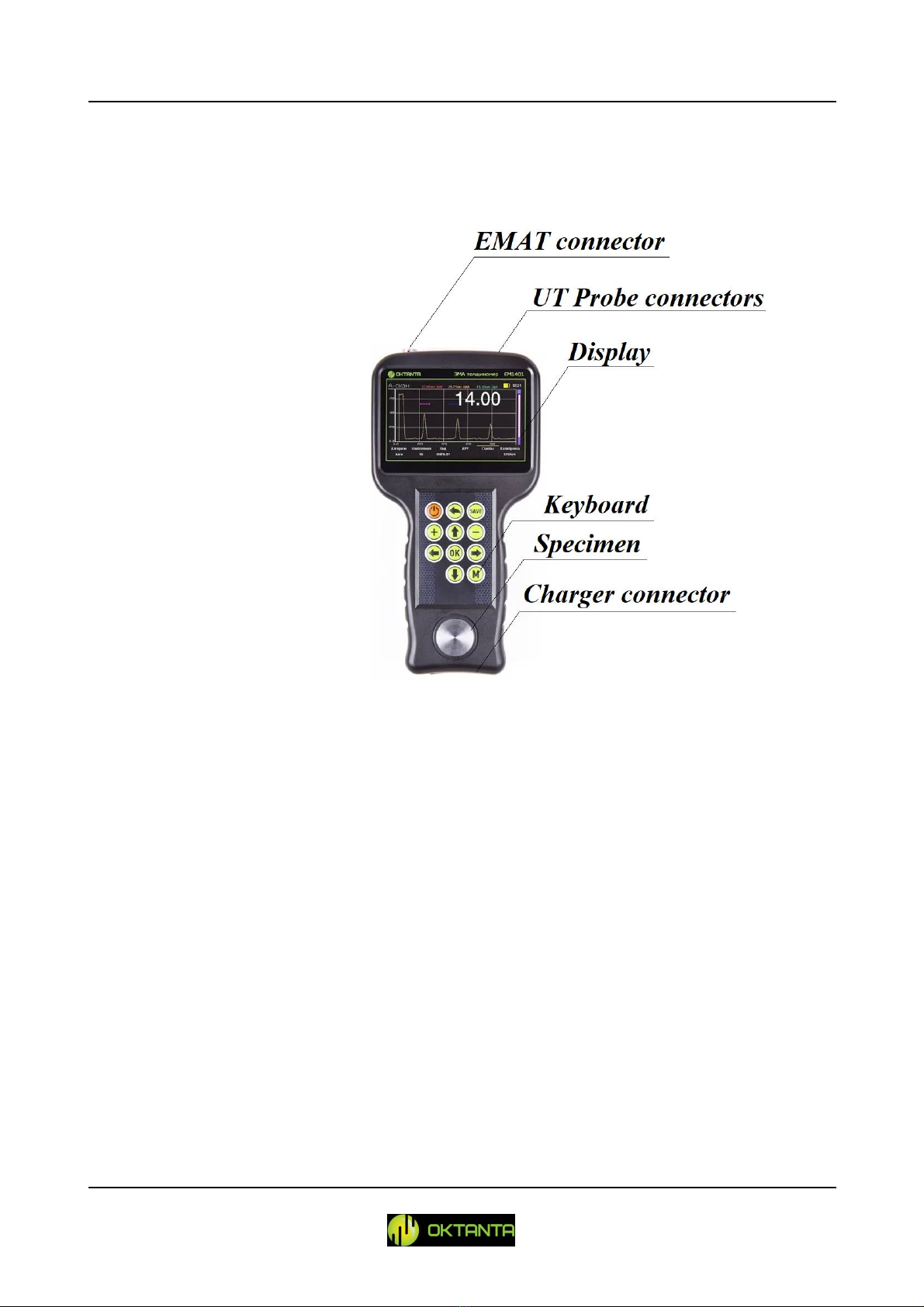

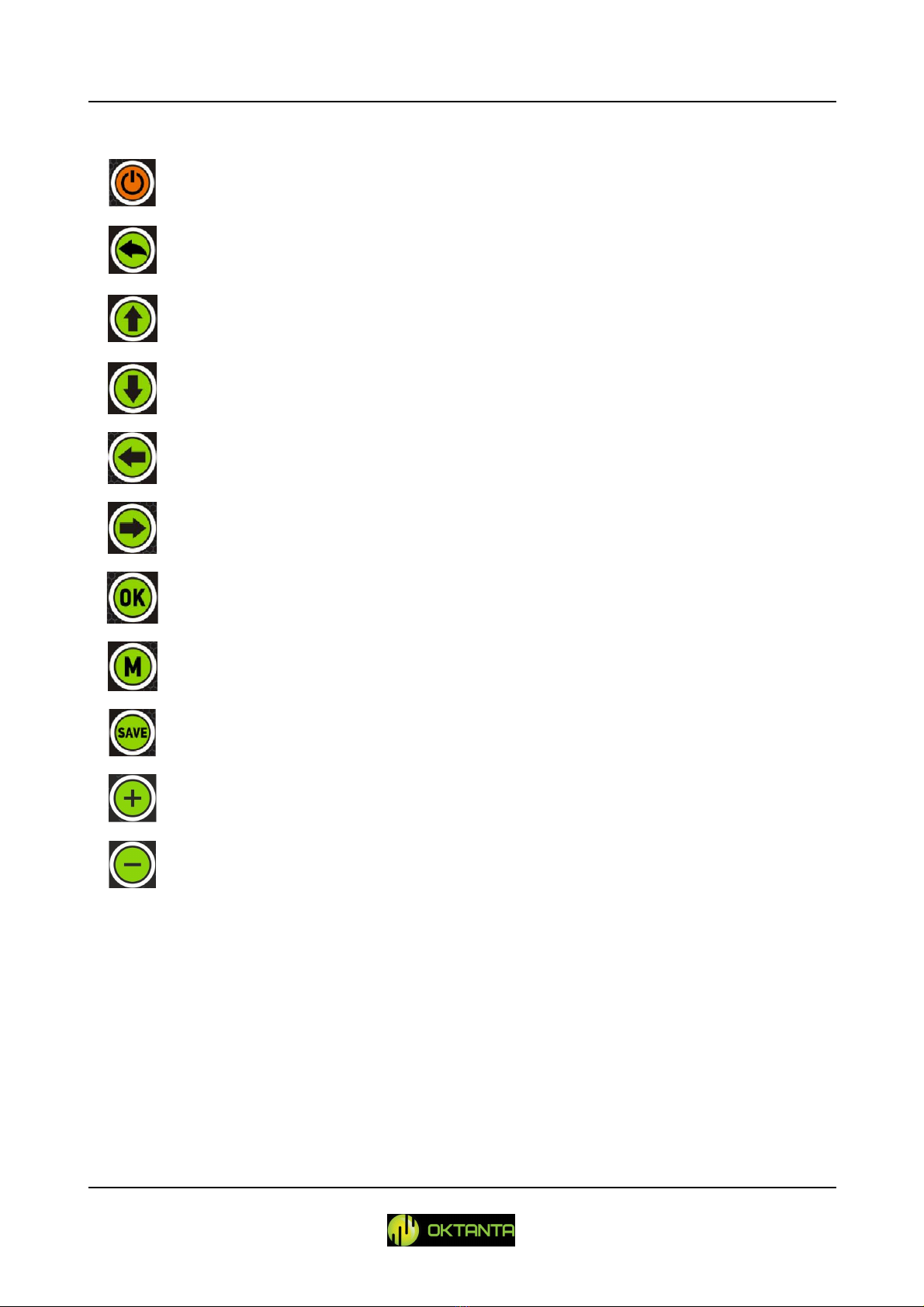

OPERATION DESCRIPTION ........................................................................................... 7

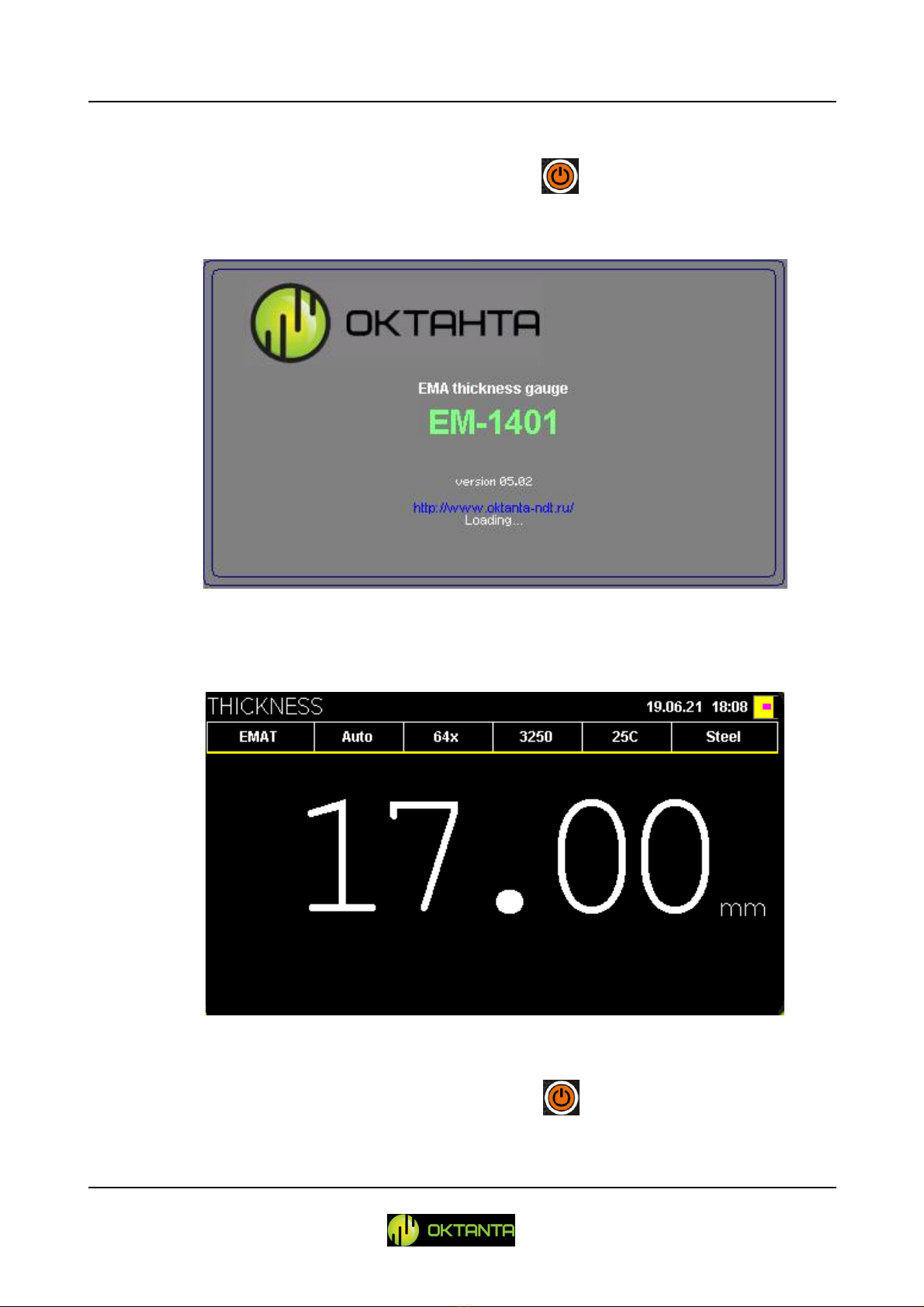

Device Switching On and Off ...................................................................................... 9

Information Display Mode Selection ...................................................................... 10

Thickness Window........................................................................................................ 11

A-scan window............................................................................................................... 18

B-scan window ............................................................................................................... 27

C-scan window ............................................................................................................... 33

User menu ........................................................................................................................ 39

Transducer Selection .................................................................................................... 41

Thickness Measurements using the Device .......................................................... 42

Data Transfer to PC ...................................................................................................... 43

Device Operation Features ......................................................................................... 44

Battery Charge ................................................................................................................ 44

DEVICE CALIBRATION TEST PROCEDURE ...................................................... 45

MAINTENANCE ................................................................................................................. 48

Transducer Replacement ............................................................................................. 48

Battery Replacement .................................................................................................... 48

TRANSPORTATION AND STORAGE ...................................................................... 49

SCOPE OF SUPPLY ........................................................................................................... 50

Basic configuration ....................................................................................................... 50

Optional equipment ...................................................................................................... 50

MANUFACTURER WARRANTY ............................................................................... 51