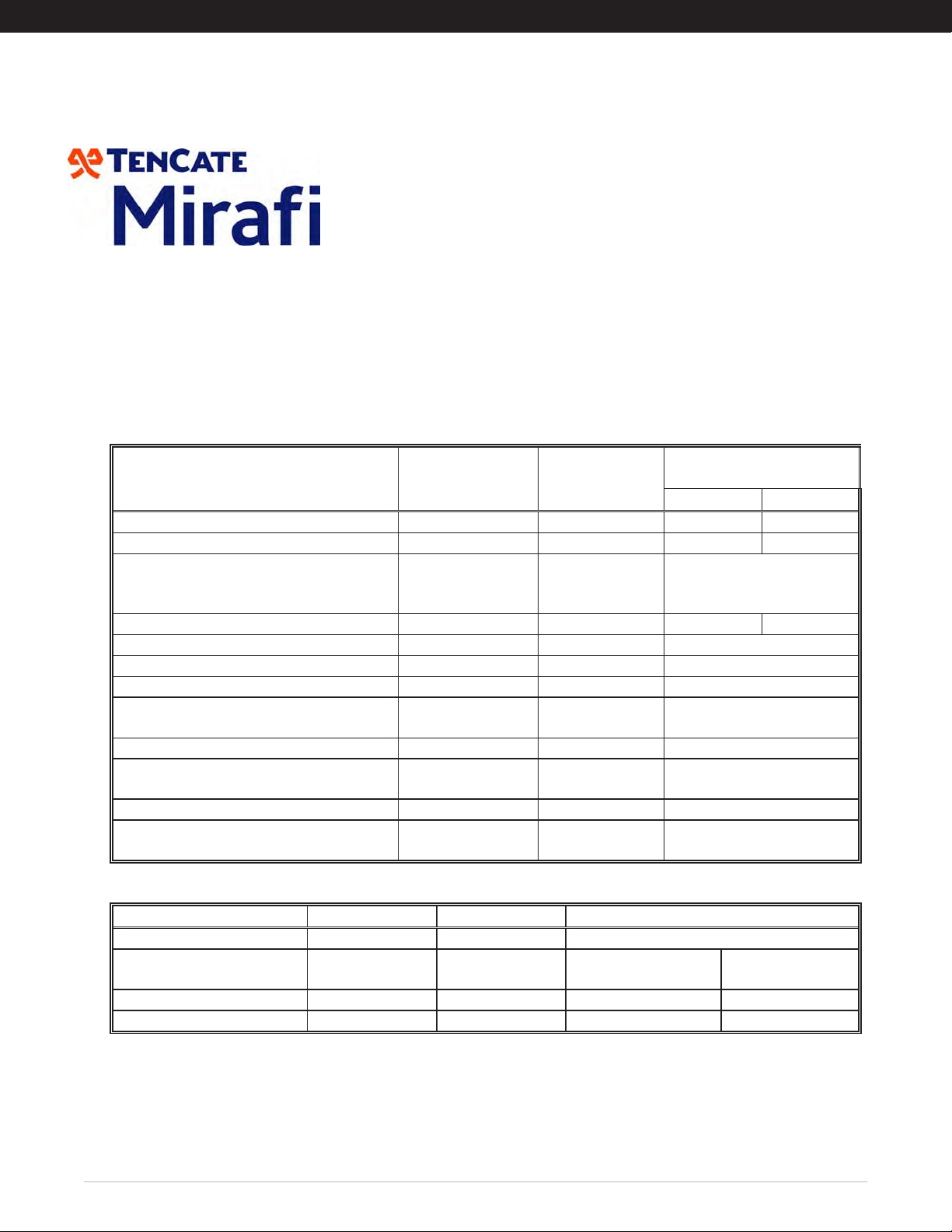

Product Specification - Structural Geogrid BX1200

The structural geogrid shall be an integrally formed grid structure manufactured of a stress resistant polypropylene material with molecular weight

and molecular characteristics which impart: (a) high resistance to loss of load capacity or structural integrity when the geogrid is subjected to

mechanical stress in installation; (b) high resistance to deformation when the geogrid is subjected to applied force in use; and (c) high resistance to

loss of load capacity or structural integrity when the geogrid is subjected to long-term environmental stress.

The structural geogrid shall accept applied force in use by positive mechanical interlock (i.e. by direct mechanical keying) with: (a) compacted soil or

construction fill materials; (b) contiguous sections of itself when overlapped and embedded in compacted soil or construction fill materials; and (c)

rigid mechanical connectors such as bodkins, pins or hooks. The structural geogrid shall possess sufficient cross sectional profile to present a

substantial abutment interface to compacted soil or particulate construction fill materials and to resist movement relative to such materials when

subject to applied force. The structural geogrid shall possess sufficient true initial modulus to cause applied force to be transferred to the geogrid at

low strain levels without material deformation of the reinforced structure. The structural geogrid shall possess complete continuity of all properties

throughout its structure and shall be suitable for reinforcement of compacted soil or particulate construction fill materials to improve their long

term stability in structural load bearing applications such as earth retention systems. The structural geogrid shall have the following characteristics:

Integrally Formed Structural Geogrid

Positive Mechanical Interlock

Product Type:

Load Transfer Mechanism:

Product Properties Index

Properties Units MD Values1XMD Values1

mm (in) 25 (1.0) 33 (1.3)

Aperture Dimensions2

Minimum Rib Thickness2 mm (in) 1.27 (0.05) 1.27 (0.05)

Load Capacity

kN/m(lb/ft) 400 (27,420) 650 (44,550)

kN/m(lb/ft) 6.0 (410) 9.0 (620)

True Initial Modulus in Use3

True Tensile Strength @ 2% Strain3

True Tensile Strength @ 5% Strain3kN/m(lb/ft) 11.8 (810) 19.6 (1,340)

Structural Integrity

%93

mg-cm 750,000

Junction Efficiency4

Flexural Stiffness5

Aperture Stability6 kg-cm/deg 6.5

Durability

95 / 93 / 90

Resistance to Installation Damage7

Resistance to Long Term Degradation8

%SC / %SW / %GP

%100

Dimensions and Delivery

The structural geogrid shall be delivered to the jobsite in roll form with each roll individually identified and nominally measuring 3.0 meters (9.8 feet) or 4.0

meters (13.1 feet) in width and 50.0 meters (164 feet) in length. A typical truckload quantity is 165 to 220 rolls. On special request, the structural geogrid

may also be custom cut to specific lengths or widths to suit site specific engineering designs.

Notes

1. Unless indicated otherwise, values shown are minimum average roll values determined in accordance with ASTM D-4759. Brief descriptions of test

procedures are given in the following notes. Complete descriptions of test procedures are available on request from Tensar Earth Technologies, Inc.

2. Nominal dimensions.

3. True resistance to elongation when initially subjected to a load measured via ASTM D6637 without deforming test materials under load before measuring

such resistance or employing "secant" or "offset" tangent methods of measurement so as to overstate tensile properties.

4. Load transfer capability measured via GRI-GG2-87. Expressed as a percentage of ultimate tensile strength.

5. Resistance to bending force measured via ASTM D-5732-95, using specimens of width two ribs wide, with transverse ribs cut flush with exterior edges of

longitudinal ribs (as a "ladder"), and of length sufficiently long to enable measurement of the overhang dimension. The overall Flexural Stiffness is

calculated as the square root of the product of machine-and cross-machine-direction Flexural Stiffness values.

6. Resistance to in-plane rotational movement measured by applying a 20 kg-cm moment to the central junction of a 9 inch x 9 inch specimen restrained at its

perimeter (U.S. Army Corps of Engineers Methodology for measurement of Torsional Rigidity).

7. Resistance to loss of load capacity or structural integrity when subjected to mechanical installation stress in clayey sand (SC), well graded sand (SW), and

crushed stone classified as poorly graded gravel (GP). The geogrid shall be sampled in accordance with ASTM D5818 and load capacity shall be measured in

accordance with ASTM D6637.

8. Resistance to loss of load capacity or structural integrity when subjected to chemically aggressive environments measured via EPA 9090 immersion testing.

Tensar Earth Technologies, Inc. reserves the right to change its product specifications at any time. It is the responsibility of the specifier and purchaser to ensure that

product specifications used for design and procurement purposes are current and consistent with the products used in each instance.

Please contact Tensar Earth Technologies at 800-836-7271 for assistance.