Olympus WINDER OM-1 User manual

Other Olympus Digital Camera manuals

Olympus

Olympus E-600 User manual

Olympus

Olympus VG-110 Instruction Manual

Olympus

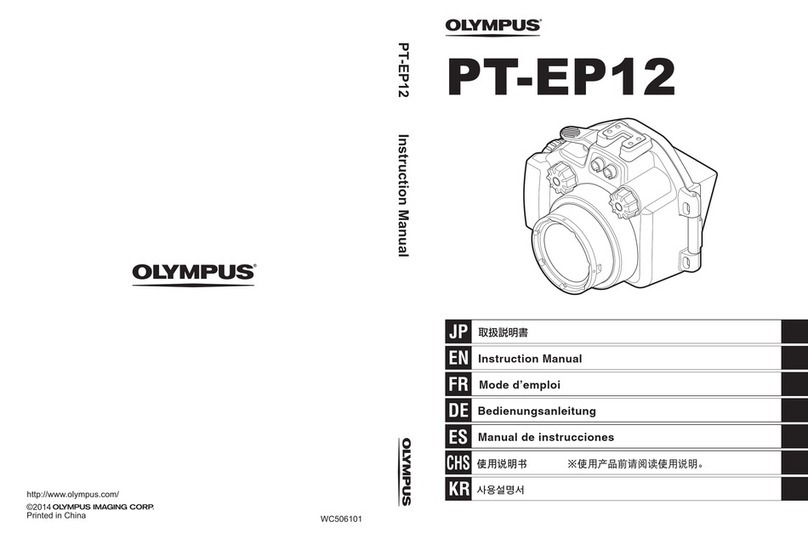

Olympus PT-EP12 User manual

Olympus

Olympus Camedia C-300 ZOOM User manual

Olympus

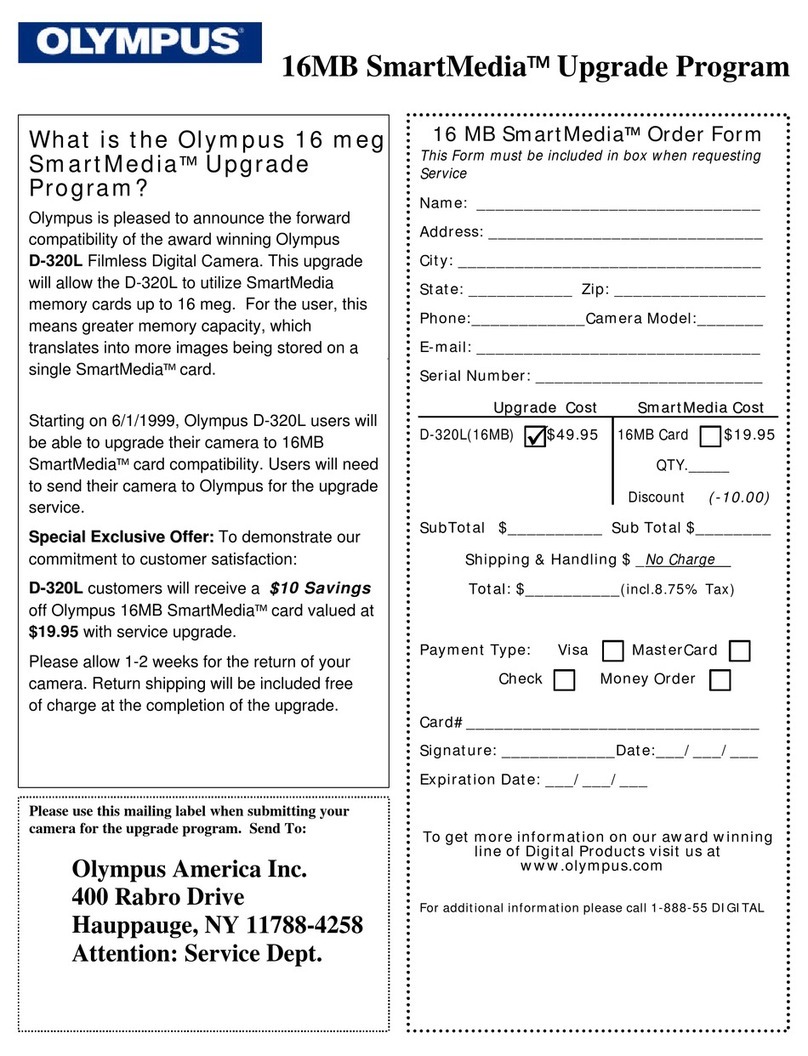

Olympus Digital Vision D-320L Installation and operation manual

Olympus

Olympus E-3 User manual

Olympus

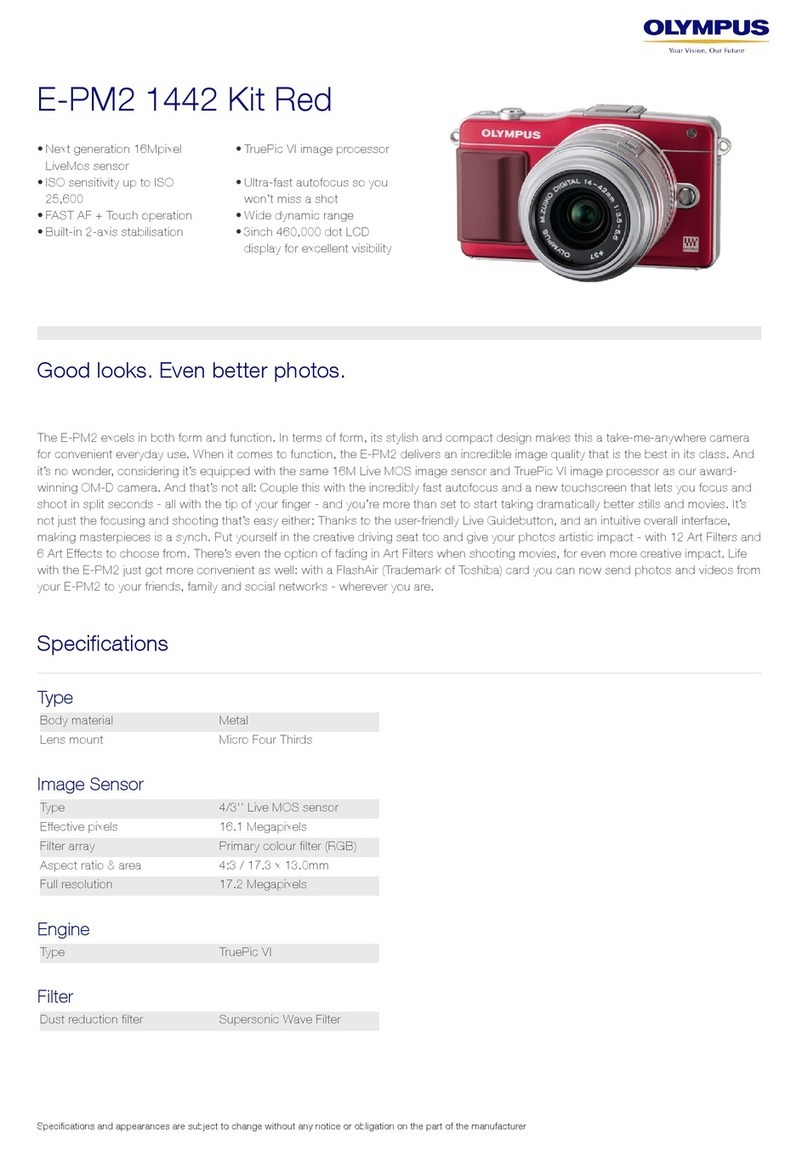

Olympus E-PM2 1442 User manual

Olympus

Olympus TRIP AF 51 User manual

Olympus

Olympus 8080 - CAMEDIA C Wide Zoom Digital Camera User manual

Olympus

Olympus FE170 - 6.0 Megapixel 3x Optical Zoom Digital... User manual

Olympus

Olympus Tough TG-820 iHS User manual

Olympus

Olympus E-P1 - Digital Camera - Prosumer Instruction Manual

Olympus

Olympus T-10 User manual

Olympus

Olympus E-500 - EVOLT Digital Camera Configuration guide

Olympus

Olympus CAMEDIA C-211 Zoom User manual

Olympus

Olympus VG-110 User manual

Olympus

Olympus Stylus 780 Installation guide

Olympus

Olympus E-P2 - PEN 12.3 MP Micro Four Thirds Interchangeable Lens Digital... Setup guide

Olympus

Olympus Stylus 1 Installation guide

Olympus

Olympus Camedia C-150 User manual