401536B-EN © OMAX Corporation February 2018

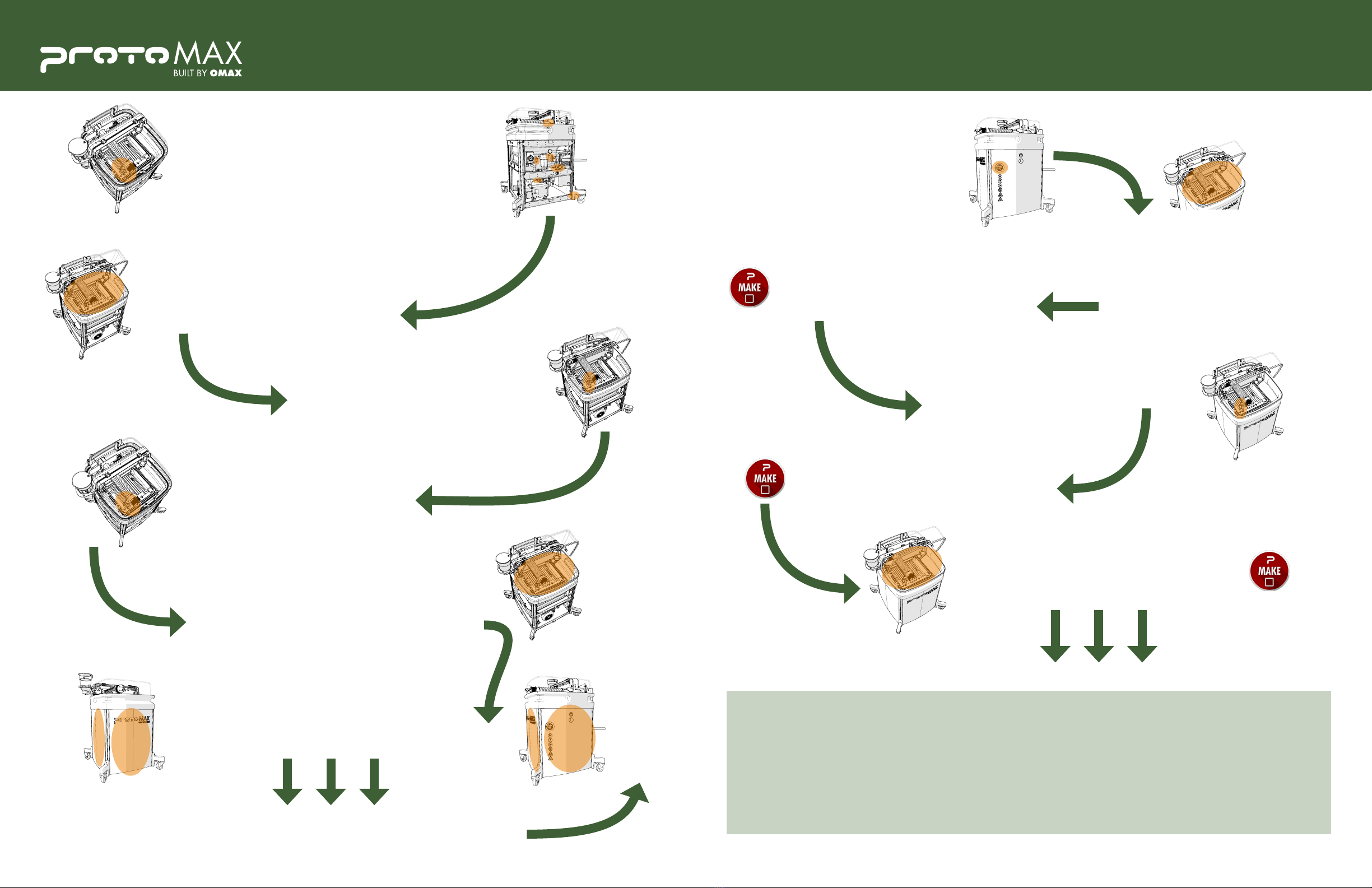

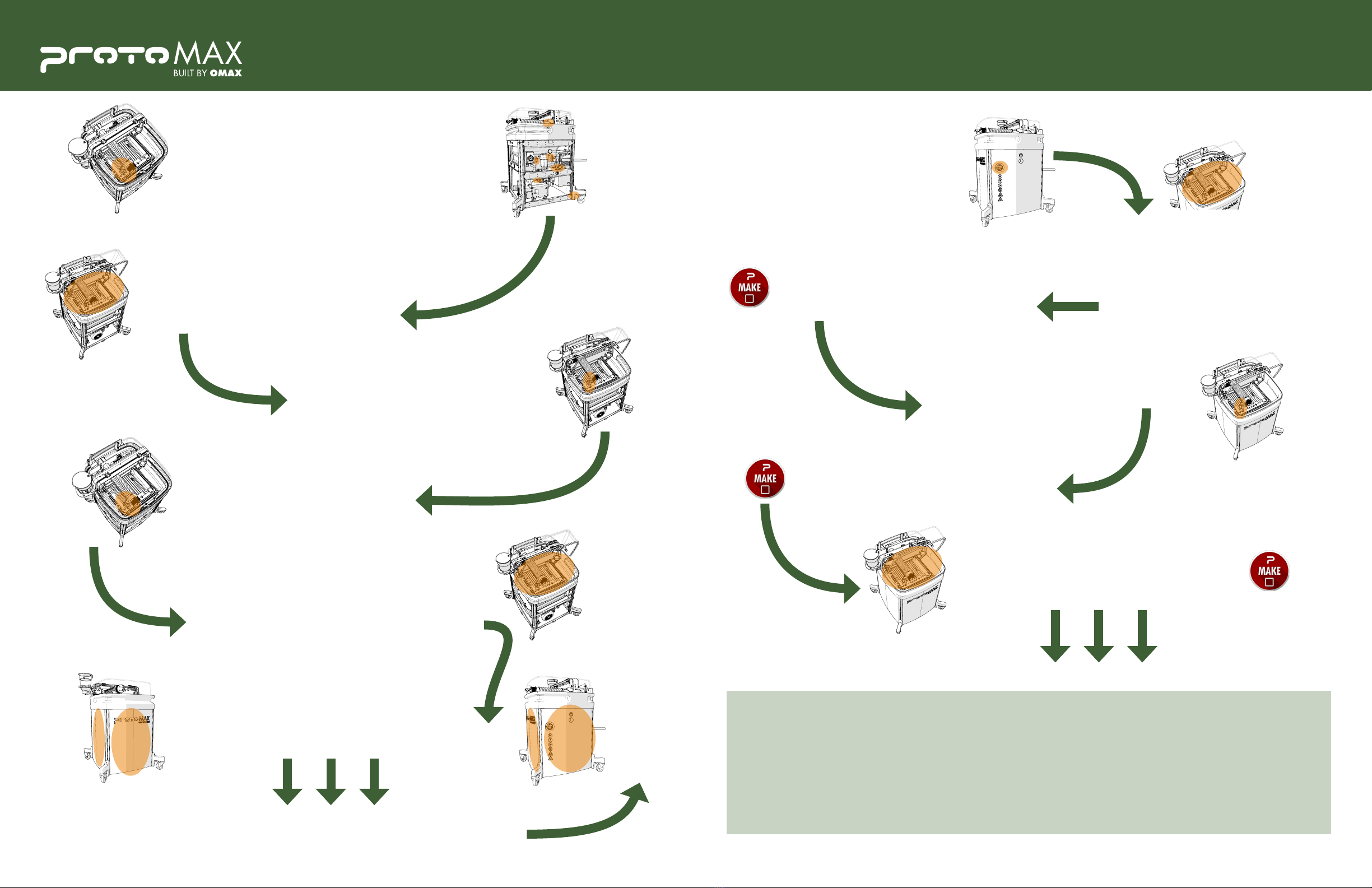

QUICK INSTALLATION OVERVIEW

Turn on the ProtoMAX and the laptop

computer.

Open the ProtoMAX MAKE application, load

a part file, and configure it for your material.

Use the MAKE application to do a dry run and

ensure the path remains on the material.

Add water to cover the material being cut. Use the

MAKE application to cut the part.

Properly set nozzle stand-off and move the

nozzle to the start position.

Open the ProtoMAX lid and place your

material on the cuing bed. Use the

Material Holding Kit to secure your

material.

OMAX is continually improving the ProtoMAX

to bring you the best in abrasive waterjet

technology. For that reason, your ProtoMAX

may differ slightly from descriptions and

images in this document. If you have any

questions, please contact us for assistance.

Verify safety feature functionality and

perform nozzle tests.

Install the plastic panels on all three sides of the ProtoMAX.

Fill the catcher tank to the top edge of

the slats and inspect tank for leaks.

Install the four part holding post assemblies to the

support frame and add the material clamps.

Install the cuing head nozzle, filter,

mixing tube, and splash guard.

PROTOMAX STARTUP

OPEN & CONFIGURE A PART FILE

CONDUCT A DRY RUN OF THE PART

ADJUST WATER LEVEL & CUT THE PART

PREPARE & POSITION THE NOZZLE

LOAD & FIXTURE MATERIAL

SUPPORT INFORMATION

PERFORM SYSTEM & NOZZLE TESTS

INSTALL SIDE PANELS

CONGRATULATIONS, YOUR PROTOMAX IS READY TO USE!

NOW LET’S CUT YOUR FIRST PART.

CONGRATULATIONS, YOU’VE CUT YOUR FIRST PROTOMAX PART!

FILL THE CATCHER TANK

INSTALL THE MATERIAL HOLDING KIT

INSTALL THE NOZZLE

Flush the high-pressure plumbing and check for

leaks on all the water fiings.

NOTE: Visually inspect high-pressure plumbing

fiings from a safe distance (16” minimum).

FLUSH THE SYSTEM

MAIN WEBSITE: protomax.com

ONLINE SUPPORT: protomax.com/support

TECHNICAL SUPPORT: 1.818.647.1994

PROTOMAX COMMUNITY: community.protomax.com

ADDRESS: 21409 72nd Ave S

Kent, WA 98032