ECD 15B / 40B / 90B / 150B - Installation and operating manual

9

Operating modes

NORMAL

When sensor detects condensate the valve opens up to one second to discharge. The exact

period depends on type of a drain. Minimal time between two discharges is 5 seconds.

OVERLOAD

If sensor detects condensed water continuously for 90 seconds, drain enters overload mode.

In this mode, the valve is opened longer and the time between discharges is shorter.

Therefore, the amount of discharged condensate is doubled. This mode lasts for five

minutes. In case the reservoir empties during overload mode, the drain enters normal mode

again. Otherwise, it goes into alarm mode.

ALARM

If drain was still not able to discharge all condensate it enters alarm mode. In this mode, the

valve is opened for five seconds every half minute. In case the reservoir empties during

alarm mode, drain enters normal mode again.

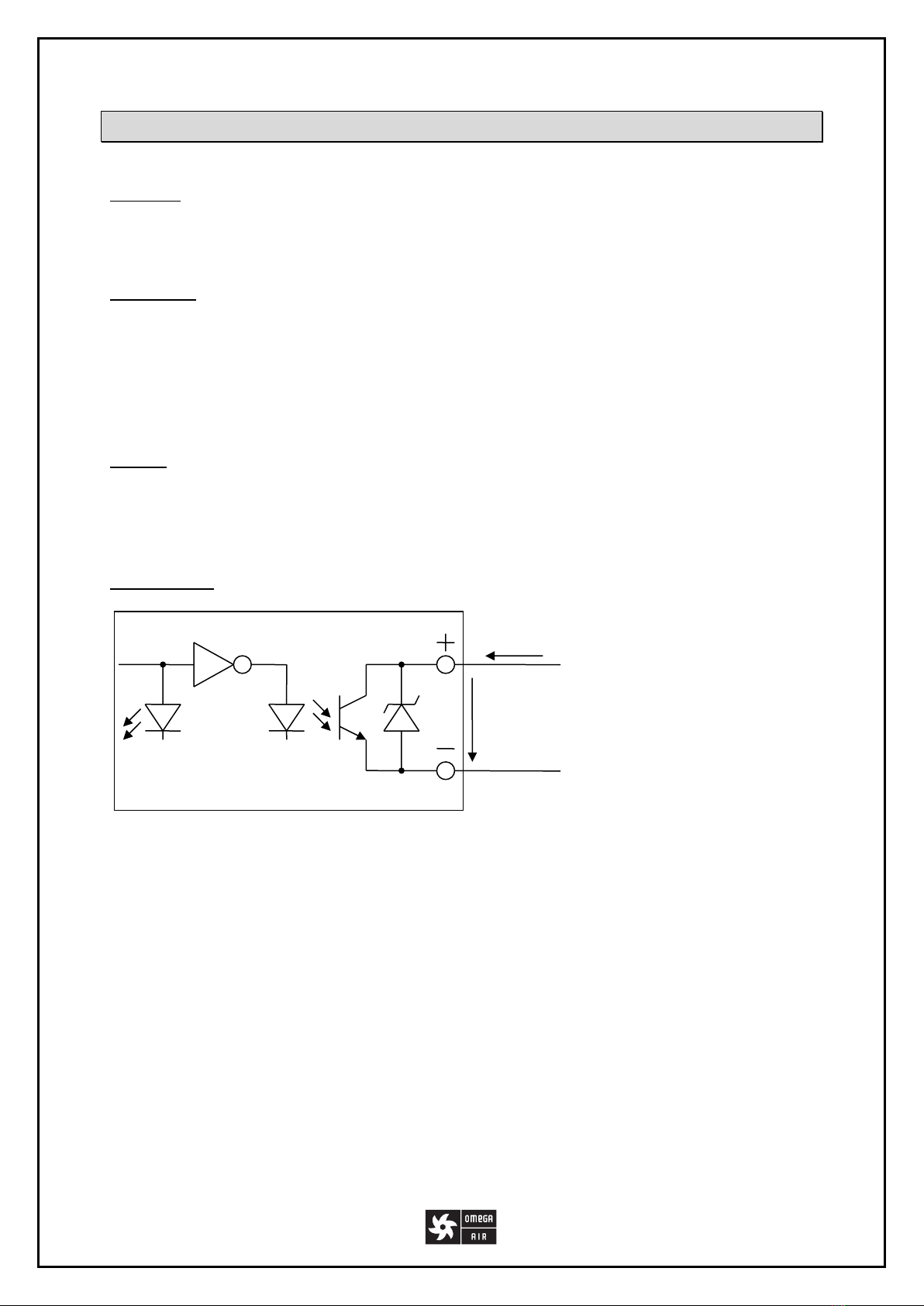

Alarm output

The ECD comprises an alarm output that is voltage free. The output is connected to the red

signal logically. The output is in high impedance state when the red LED is on or when ECD

electric supply is off.

LED

OUT

OUT

out

out