3

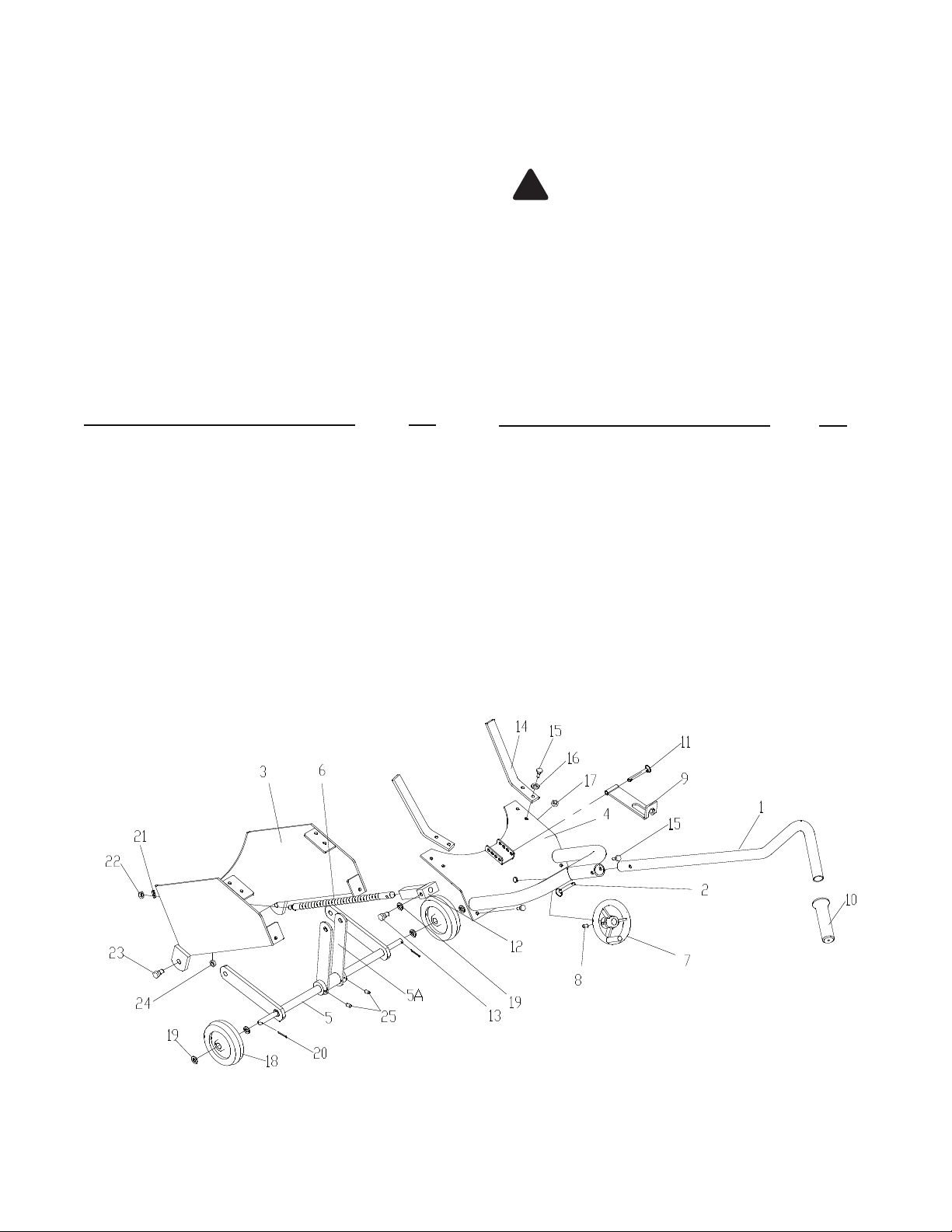

ASSEMBLY

(refer to gure 4 on page 4)

1. Thread the connecting block (#12) to middle rod (#6),

then secure to base (#3) with M10 nut and washer

(#21 & 22).

2. Secure top cover (#4) and two holding arms (#14) to

base (#3) with M6x25 bolts, washers & nuts (#15,

16 & 17)

3. Attach wheel axle (#5) to base (#3) with M12x40 bolts

& nuts (#23 & 24)

4. Attach wheels (#18) and washers (#19) to wheel axle

(#5), then secure with cotter pins (#20)

5. Secure the axle links (#5A) of wheel axle (#5) to

connecting block (#12) with M12 bolts and washers

(#13 & 19).

6. Attach hook bracket (#9) to top cover (#4) and secure

with lock pin (#11)

7. Attach angle adjustable wheel (#7) to middle rod (#6)

with set screw (#8).

8. Attach handle (#1) to top cover (#4) with lock pin

(#2).

9. Insert handle grip (#10) to handle (#1).

OPERATION

1. Prepare the brake drum or brake drum/hub assembly

for removal according to the instructions in vehicle

service manual.

2. Place drum handler in a horizontal position.

3. Turn the angle adjustable wheel until the drum han-

dler is in its lowest postion.

4. Position the handler under the drum until the holding

arms meet the outer surface of the drum.

5. Turn the angle adjustable wheel clockwise until the

handler meets the lower surface of the drum.

6. Lower the handle to slightly lift the drum. Pull the

handler and drum back, away from the brake as-

sembly.

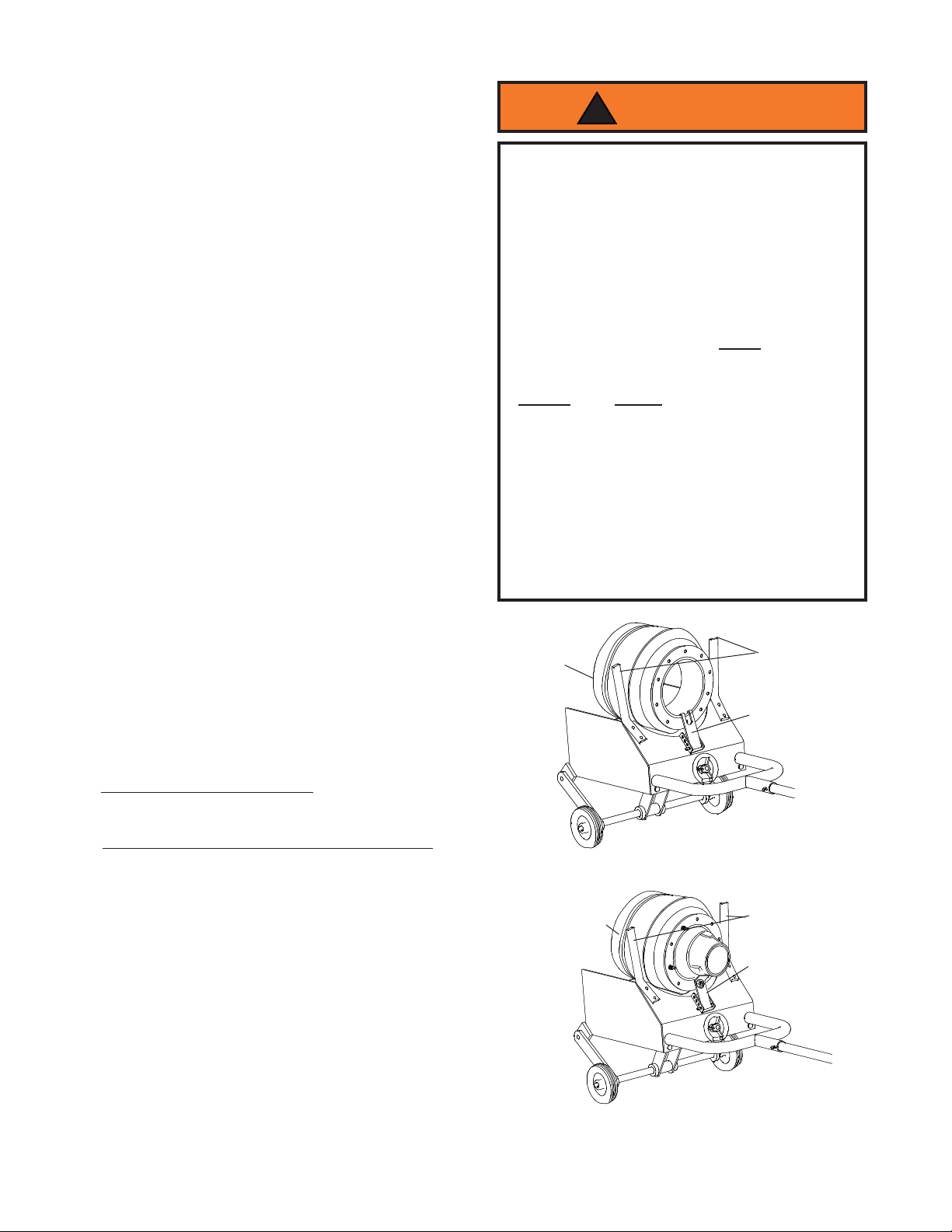

7. Removing/installing drum only:

Flip the hook bracket into the hub opening of the

drum as shown in gure 2.

Removing/installing drum and hub as assembly:

Position the hook bracket reverse as shown in gure

3 to allow a wheel nut to secure hook to drum/hub

assembly.

8. It may be necessary to adjust the hook. Remove the

hook lock pin, and move the hook bracket to any one

of four hole locations.

9. Pull the drum completely away from the brake as-

sembly. Slowly and carefully lift the handle to place

the drum face down on the oor, being cautious of

the transfer of load weight.

Note: Reverse the process to Install the brake drum

back to the brake assembly. Be sure to align the drum

with the studs and follow the instructions in the vehicle

service manual.

Hook Position

(for drum only)

Figure 2 - Illustration for removing/installing drum

Brake Drum

Holding Arms

Hook Position

(for drum/hub

assy.)

Drum/Hub Assy.

Figure 3 - Illustration for removing/installing drum/hub

assembly

Holding Arms

• Study, understand, and follow all printed mate-

rials provided with and on this device before use.

• Ensure that vehicle is chocked, lifted, and sup-

ported by adequately rated jack stands before

using this product!

• Use only for removal, installation, and transport

of brake drum/hub assys which nest and can be

secured within the bed frame and holding arms.

• DO NOT overload. Bending, bowing, or cracked

components are visible evidence of overloading.

If such deformation is noted, STOP, immediately

discontinue use and transfer load to a drum han-

dler of greater capacity.

• Secure drum before transporting.

• Use only on hard, level surface.

• Raise and lower the brake drum slowly.

• Always wear steel-toed shoes when using this

device.

• Brake drum dust is hazardous to your health.

Consult Federal, State and local regulations con-

cerning the safe handling of asbestos and what

precautions to take when handling.

• Failure to heed these markings may result in

personal injury and/or property damage.

WARNING

!