3

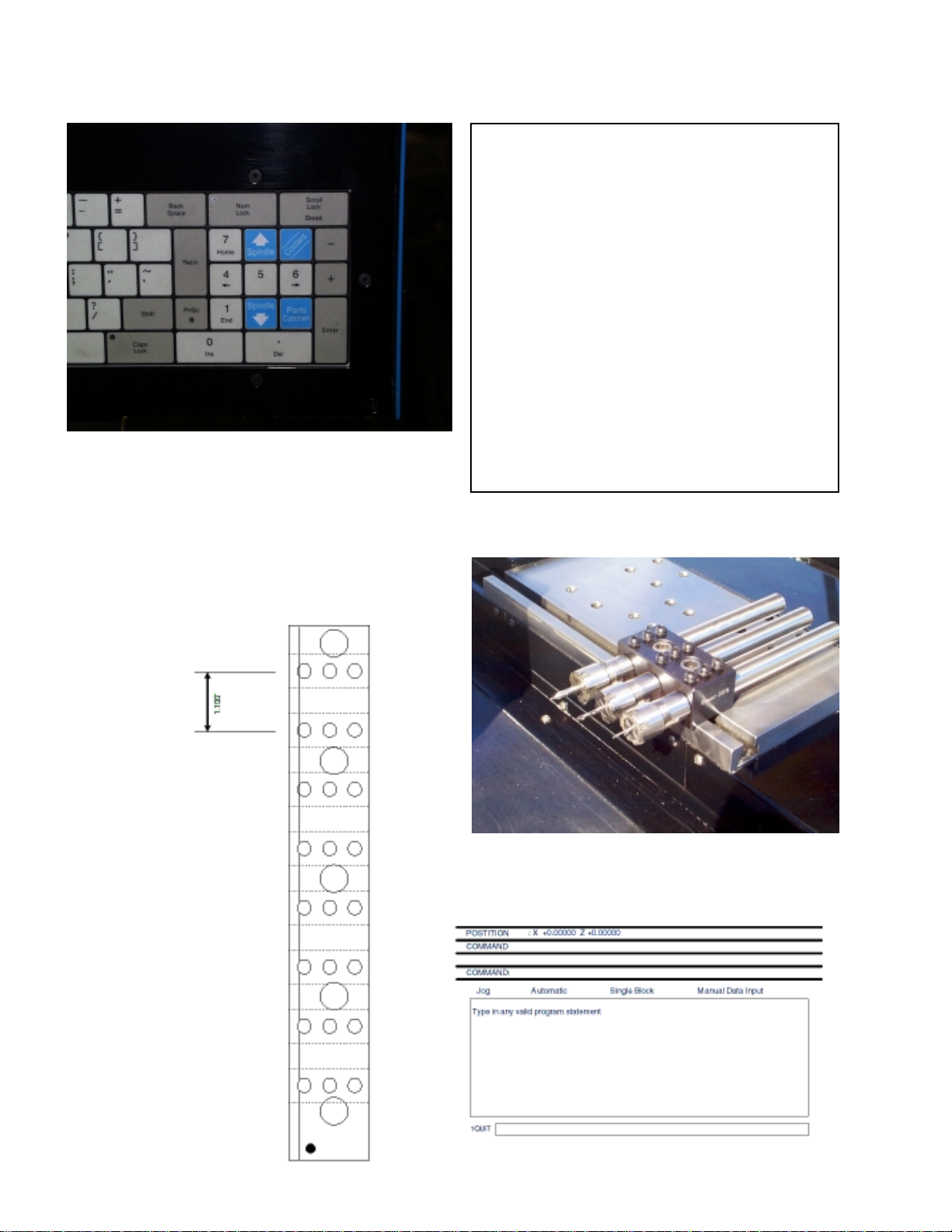

OmniTurn Control

Welcome to our world

This manual will guide first time users to startup, home, enter, edit, and

run programs. First we will discuss the control layout. On the upper left-

hand side of the control you will see a large red button called emergency

stop. (1). Twist and pull, button should snap out. Next check the other E

stop located on the palm box make sure this is also disengaged. (2). Now

you are ready to press the yellow control on button. (3). The first screen

that comes up will ask you if you want to back up your files on a disc.

Press the letter Y for yes or N for no on the keyboard. The next screen

will prompt turn servos on. The blue button in figure (4) is the servo on

button, press this now. This brings you to the Jog menu screen with a

prompt “HOME MUST BE ESTABLISHED”.

See page 5.

There are two other buttons on the control a green button (5) which is

cycle start and a small red button (6) that is motion stop. Note: The cycle

startbuttononthecontrolisonlyactiveonretrofitswithouttheACspindle

drives option. Otherwise the two black palm buttons on the operator sta-

tion activate cycle start fig (7). The motion stop button is used to stop

slide motion while running a program in the automatic mode. Below the

emergency stop button is the spindle speed pot. This will adjust the speed

of the spindle. Note: This only works with the AC spindle drive option.

Under the speed pot is the spindle on / off switch (8). This is used to

manually stop the spindle.

Jog Menu

[Chapter 1, Page 1.3 - 1.7 in OmniTurn Programming Manual]

The jog menu allows the operator to perform several functions. 1.Estab-

lishing home. 2. Move slide manually either incrementally or continu-

ously. 3.Set tool offsets

The first three choices on the menu are continuous jog moves made in

Inches per minute feed rates 1: slow 1 IPM 2: medium 10 IPM 3: 100

IPM.

To activate these moves select 1, 2, and 3, on the main keypad. The

joystick on the control will move the slides in one of four directions: X +,

X- Z+ or Z-. Choose speed number 2:10 IPM. Then point the joystick

(9) down in the X+ direction and hold. The slide will move toward you at

10 IPM until you release it. Now push the joystick to the left in the Z-

direction. Try the different speeds and get comfortable with this mode.

Use caution when jogging in the fast mode, and be careful not to over

travel the axis’s. Also if there are tools mounted on the slide be aware of

their position in relationship to the spindle or work piece.

( 1 ) ( 2 )

( 3 ) ( 4 )

( 5 ) ( 6 )

( 7 ) ( 8 )

( 9 )