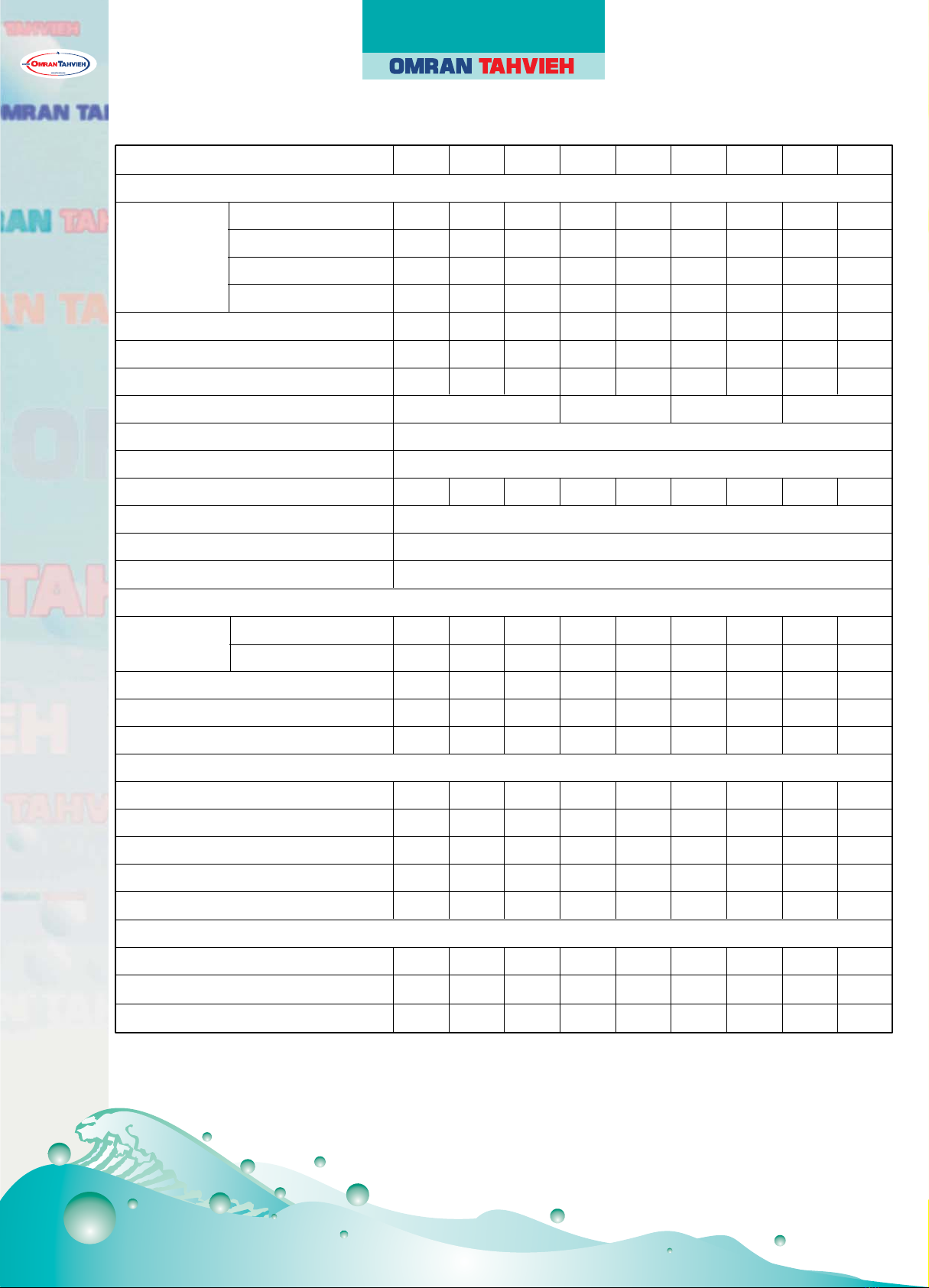

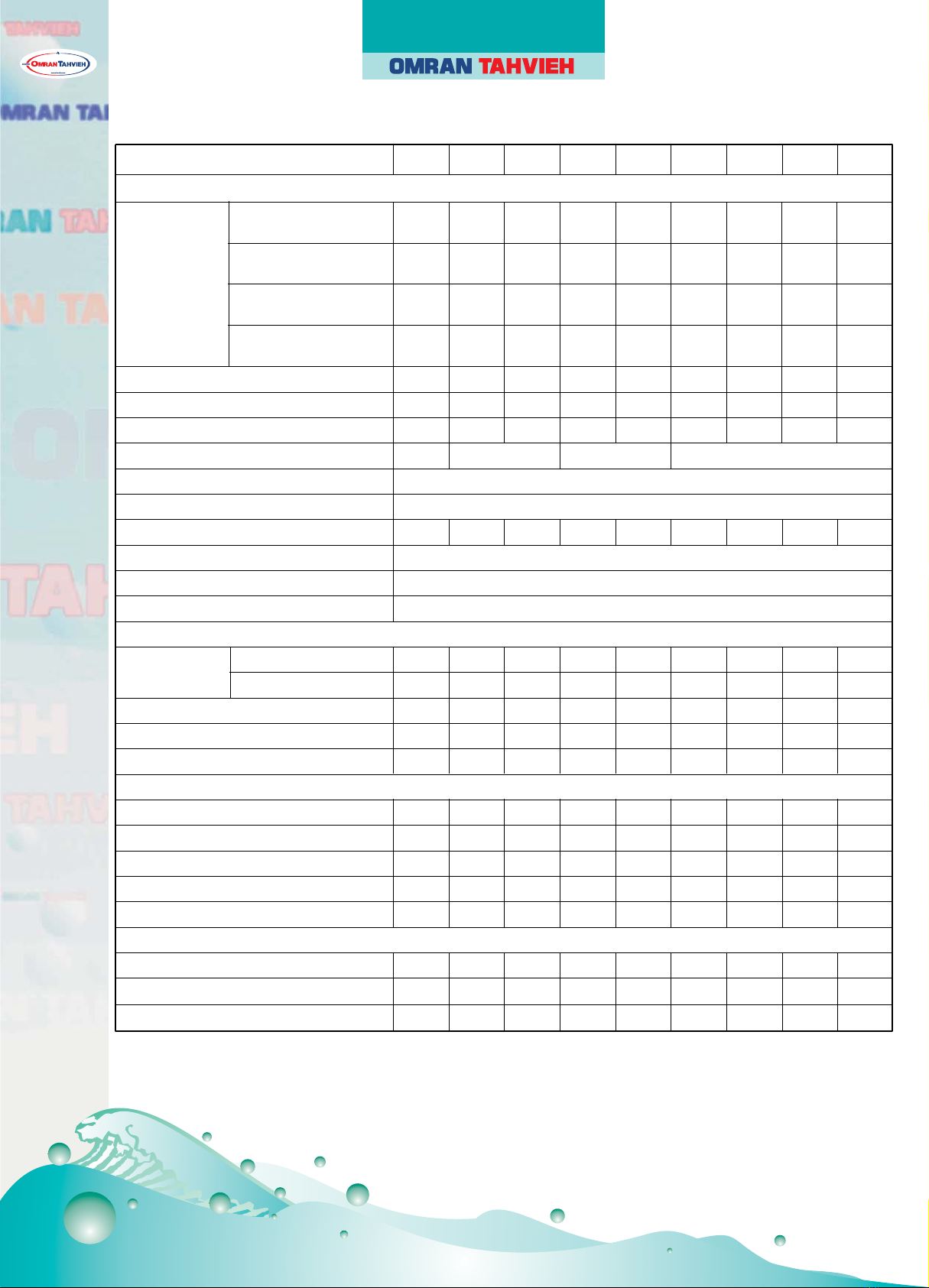

AIR COOLED CHILLERS

STANDARD CONTROL & SAFETY DEVICES

8

MICROPROCESSOR CONTROLLER: This controller monitors analog and digital inputs to achieve precise control &

safety functions of the unit.( optional )

COMPRESSOR MOTOR INTERNAL OVERLOAD: The internal overload protects the compressor and senses the mo-

tor winding temperature in case of overload.

STARTERS: The starter is operated by the control circuit and provides power to the compressor motors. These devices

are rated to handle safely both RLA and LRA of motors.

UNDER VOLTAGE AND PHASE PROTECTION: Protects against low incoming voltage as well as single phasing, phase rever-

sal and phase imbalance by de-energizing the control circuit. It is an automatic reset device, but it can be set up for manual reset.

CRANKCASE HEATERS: Each compressor has crankcase heater. The compressor crankcase heater is always on

when the compressors are de-energized. This protect the system against refrigerant migration, oil dilution and potential

compressor failure.

SAFETY VALVE: This valve protects the unit against high discharge pressure in the system due to malfunction of high

pressure switches.

HIGH PRESSURE SWITCH: This switch provides an additional safety protection in the case of excessive discharge pressure.

UNIT ON-OFF SWITCH: ON-OFF switch is provided for manually switching the unit control circuit.

INDICATOR LIGHTS: lights indicates power ON to the units .

THERMOSTATIC EXPANSION VALVE: Thermostatic expansion valve is used to regulate the refrigerant flow to the

water cooler and maintain a constant superheat.

FILTER DRIER (REPLACEABLE CORE TYPE): Refrigerant circuits are kept free of harmful moisture, sludge, acids and

oil contaminating particles by the filter drier.

CONTROL CIRCUIT TRANSFORMER ( optional) : A factory mounted and wired control circuit transformer is furnished

eliminating the need for running a separate 115 volt power supply to the unit control circuit.

SIGHT GLASS: A moisture indicating sight glass installed in the liquid line. An easy-to-read color indicator shows mois-

ture contents and provides a mean for checking the system refrigerant charge.

LIQUID LINE SOLENOID VALVE: Closes when the compressor is off to prevent any liquid refrigerant from accumulating

in the water cooler during the off cycle.

DISCHARGE LINE MUFFLER ( optional ) : Discharge line mufflers are installed to eliminate noise due to refrigerant

pulsation.

VIBRATION ELIMINATOR: To eliminate the vibration transmitted from the compressor to the pipings and unit structure.

HOT GAS BYPASS SYSTEM (optional ) : Hot gas bypass is provided on the lead circuit to permit operation of the system

down to 50% of its unloaded capacity. Under low ambient condition, it controls temperature by eliminating the need to cycle

the compressoron and off, ensuring narrow temperature swing and lengthen the life span of the compressor .

WATER FLOW SWITCH (optional ): Paddle type field adjustable flow switch for water cooler circuits. Interlock into

unit safety circuits so that the unit will remain off until water flow is determine.

UNIT MOUNT SPRING ISOLATORS (optional): Designed for deflection. This housed spring assemblies have a

neoprene friction pad on the bottom to prevent vibration transmission.

CIRCUIT BREAKERS: Protects against compressor branch circuit fault. When tripped (manually or automatically), the

breaker opens the power supply to the compressor and control circuit through auxiliary contacts.

ACCESSORIES