K8DT-VS

10

1. Do not use or store the product in the following locations.

•Locations subject to water or oil

•Outdoor locations or under direct sunlight

•Locations subject to dust or corrosive gases (sulfurizing gases,

ammonia gases, etc.)

•Locations subject to rapid temperature changes

•Locations prone to icing and dew condensation

•Locations subject to vibration and large shocks

•Locations subject to wind and rain

•Locations subject to static electricity or noise

•Locations subject to insects or small animals

2. Use and store the product in a location where the ambient

temperature and humidity are within the specified ranges. If

applicable, provide forced cooling.

3. Check terminal polarity when wiring and wire all connections

correctly. The power supply terminals do not have polarity.

4. Do not wire the input and output terminals incorrectly.

5. Make sure the power supply voltage and loads are within the

specifications and ratings for the product.

6. Make sure the ferrule terminals for wiring are of the specified size.

7. The stripping length is 8 mm. Insert the wires all the way to the

back.

8. Do not connect anything to terminals that are not being used.

9. Use a power supply that will reach the rated voltage within 1

second after the power is turned ON.

10.Keep wiring separate from high voltages and power lines that draw

large currents. Do not place product wiring in parallel with or in the

same path as high-voltage or high-current lines.

11.Do not install the product near equipment that generates high

frequencies or surges.

12.The product may cause incoming radio wave interference. Do not

use the product near radio wave receivers.

13.Install an external switch or circuit breaker and label it clearly so

that the operator can quickly turn OFF the power supply.

14.Make sure the indicators operate correctly. Depending on the

application environment, the indicators may deteriorate

prematurely and become difficult to see.

15.Do not use the product if it is accidentally dropped. The internal

components may be damaged.

16.Be sure you understand the contents of this catalog and handle

the product according to the instructions provided.

17.Do not install the product in any way that would place a load on it.

18.When discarding the product, properly dispose of it as industrial

waste.

19.When using the product, remember that the power supply

terminals carry a high voltage.

20.The product must be handled only by trained electrician.

21.Prior to operation, check the wiring before you supply power to the

product.

22.Do not install the product immediately next to heat sources.

23.Perform periodic maintenance.

24.Do not wire anything to the release holes.

25.Do not tilt or twist a flat-blade screwdriver while it is inserted into a

release hole on the terminal block. The terminal block may be

damaged.

26.Insert a flat-blade screwdriver into the release holes at an angle.

The terminal block may be damaged if the screwdriver is inserted

straight in.

27.Do not allow the flat-blade screwdriver to fall when you are holding

it in a release hole.

28.Do not bend a wire past its natural bending radius or pull in it with

excessive force. Doing so may break the wires.

29.Do not insert more than one wire into each terminal insertion hole.

30.To prevent wiring materials from smoking or igniting, confirm wire

ratings and use the wiring materials given in the following table.

31.Use only the specified wires for wiring.

32.When wiring the terminals, allow some leeway in the wire length.

33.Make sure that the power supply is turned OFF before you change

any DIP switch setting.

Observe the following operating methods to

prevent failure and malfunction.

1. Use the power supply voltage, input power, and other power

supplies and converters with suitable capacities and rated outputs.

2. Do not use the Relay in circuits with waveform distortion. Error will

be large due to waveform distortion.

3. Error will be large if the product is used for thyristor or inverter

control.

4. When cleaning the product, do not use thinners or solvents. Use

commercial alcohol.

5. If you use stranded wires, make sure that there are no loose wire

strands.

6. If you wire crossovers and connect terminal blocks in parallel, a

large current will flow. Make sure that the current does not exceed

10 A.

7. The terminal block may be damaged if the recommended tool is

not used. Use the recommended flat-blade screwdriver to operate

the release holes.

Correct Mounting Direction, Mounting, and

Removing

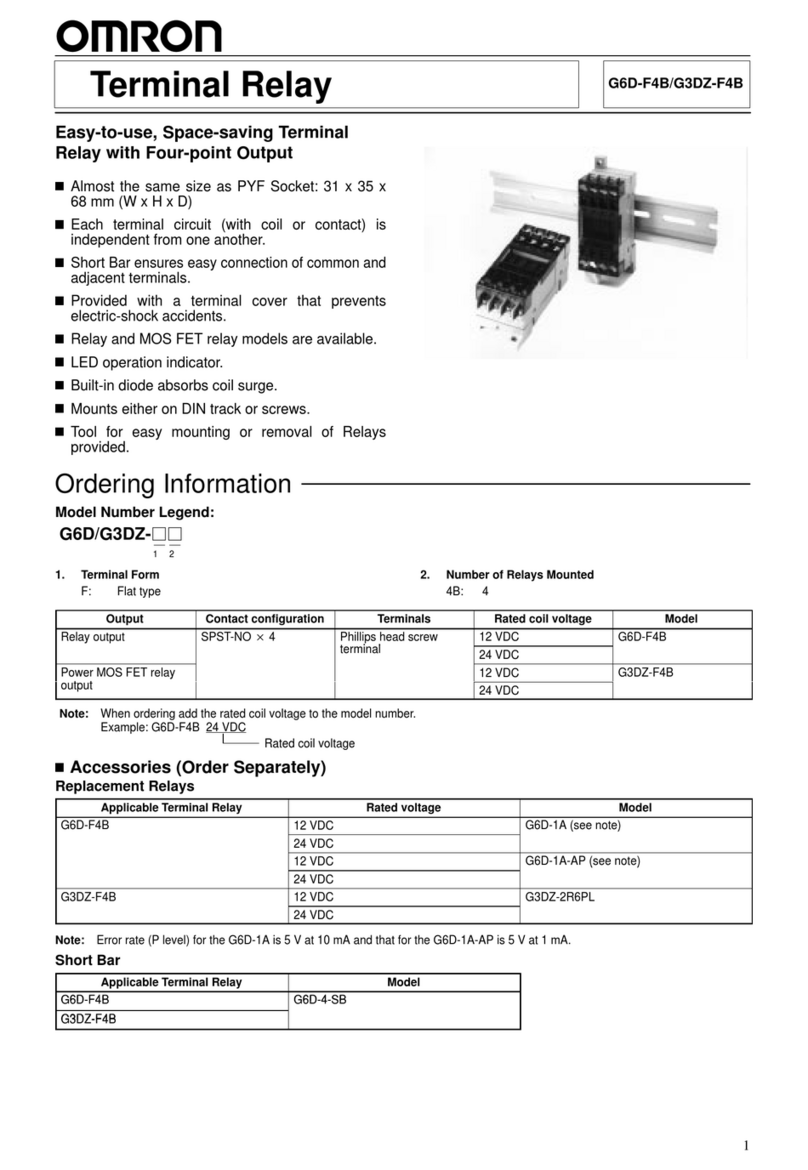

Mounting to DIN Track

To mount the Relay to a DIN Track, hook the Relay onto the DIN

Track and press the Relay in the direction of the arrow until you hear

it lock into place.

Removing from the DIN Track

To remove the Relay, insert a screwdriver into the hook on the top or

bottom and pull out the hook to release the Relay.

• Leave at least 30 mm of space between the product and other

devices to allow easy installation and removal.

Precautions for Safe Use

Recommended wire Stripping length

(Ferrules not used)

0.25 to 1.5mm2/Equivalent to AWG24 to 16 8 mm

Precautions for Correct Use

PFP-100N (100 cm)

PFP-50N (50 cm)

Applicable DIN Tracks

30 mm min.