NCP1608BOOSTGEVB

http://onsemi.com

7

Rsense +0.5

3.62 +0.138 W

The current sense resistor is selected as 0.125 Wfor

decreased power dissipation. The resulting maximum

inductor peak current is 4 A. Since the MOSFET continuous

current rating is 7 A (for TC= 100°C as specified in the

manufacturer’s datasheet) and the inductor saturation

current is 4.7 A, the maximum peak inductor current of 4 A

is sufficiently low.

The power dissipated by Rsense is calculated using

Equation 18:

PRsense +IM(RMS) 2@Rsense (eq. 18)

PRsense +1.272@0.125 +0.202 W

5. The output capacitor (Cbulk) rms current is

calculated using Equation 19:

IC(RMS) +2

Ǹ@32 @Pout 2

9@p@Vac @Vout @h2*Iload(RMS) 2

Ǹ(eq. 19)

IC(RMS) +2

Ǹ@32 @1002

9@p@85 @400 @0.922*0.252

Ǹ+0.7 A

The value of Cbulk is calculated in Step 5 to ensure a ripple

voltage that is sufficiently low to not trigger OVP. The value

of Cbulk may need to be increased so that the rms current

does not exceed the ratings of Cbulk.

The voltage rating of Cbulk is required to be greater than

Vout(OVP). Since Vout(OVP) is 421 V, Cbulk is selected to have

a voltage rating of 450 V.

DESIGN STEP 7: Supply VCC Voltage

The typical method to charge the VCC capacitor (CVcc) to

VCC(on) is to connect a resistor between Vin and VCC. The

low startup current consumption of the NCP1608 enables

most of the resistor current to charge CVcc during startup.

The low startup current consumption enables faster startup

times and reduces standby power dissipation. The startup

time (tstartup) is approximated with Equation 20:

tstartup +

CVCC @VCC(on)

2

Ǹ@Vac

Rstart *ICC(startup)

(eq. 20)

Where ICC(startup) = 24 mA (typical).

If CVcc is selected as a 47 mF capacitor and Rstart is

selected as 660 kW, tstartup is equal to:

tstartup +47 m@12

2

Ǹ@85

660 k *24 m

+3.57 s

Once VCC reaches VCC(on), the internal references and

logic of the NCP1608 turn on. The NCP1608 includes an

undervoltage lockout (UVLO) feature that ensures that the

NCP1068 remains enabled unless VCC decreases to less than

VCC(off). This hysteresis ensures sufficient time for another

supply to power VCC.

The ZCD winding is a possible solution, but the voltage

induced on the winding may be less than the required

voltage. An alternative is to implement a charge pump to

supply VCC. A schematic is illustrated in Figure 7.

Figure 7. The ZCD Winding Supplies VCC using a

Charge Pump Circuit

+

1

4

3

2

8

5

6

7

GND

ZCD

NCP1608

+

Cin

Rstart

D1

R1

CVcc

RZCD

C3IAUX

DAUX

DRV

VCC

FB

Control

Ct

CS

C3 stores the energy for the charge pump. R1 limits the

current by reducing the rate of voltage change. DAUX supplies

current to C3 when its cathode is negative. When its cathode

is positive it limits the maximum voltage applied to VCC.

The voltage change across C3 over one period is

calculated using Equation 21:

DVC3 +Vout

N*VCC (eq. 21)

The current that charges CVcc is calculated using

Equation 22:

IAUX +C3 @fSW @DVC3 +C3 @fSW @ǒVout

N*VCCǓ

(eq. 22)

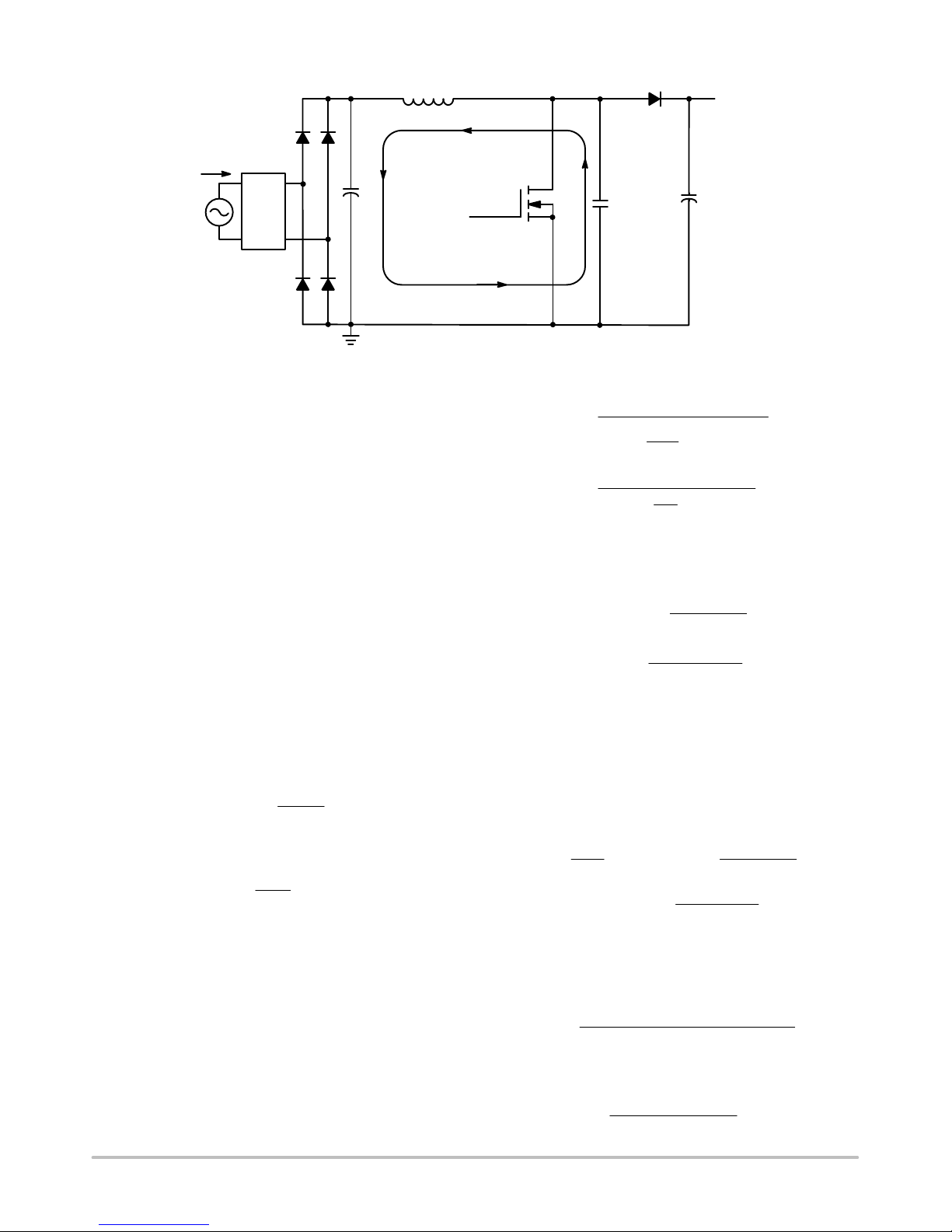

For off−line ac-dc applications that require PFC, a 2-stage

approach is typically used. The first stage is the CrM boost

PFC. This supplies the 2nd stage, which is traditionally an

isolated flyback or forward converter. This solution is

cost−effective and exhibits excellent performance. During

low output power conditions the PFC stage is not required

and reduces efficiency. Advanced controllers, such as the

NCP1230 and NCP1381 detect the low output power

condition and shut down the PFC stage by removing

PFC(VCC) (Figure 8).