GENERAL

INFORMATION

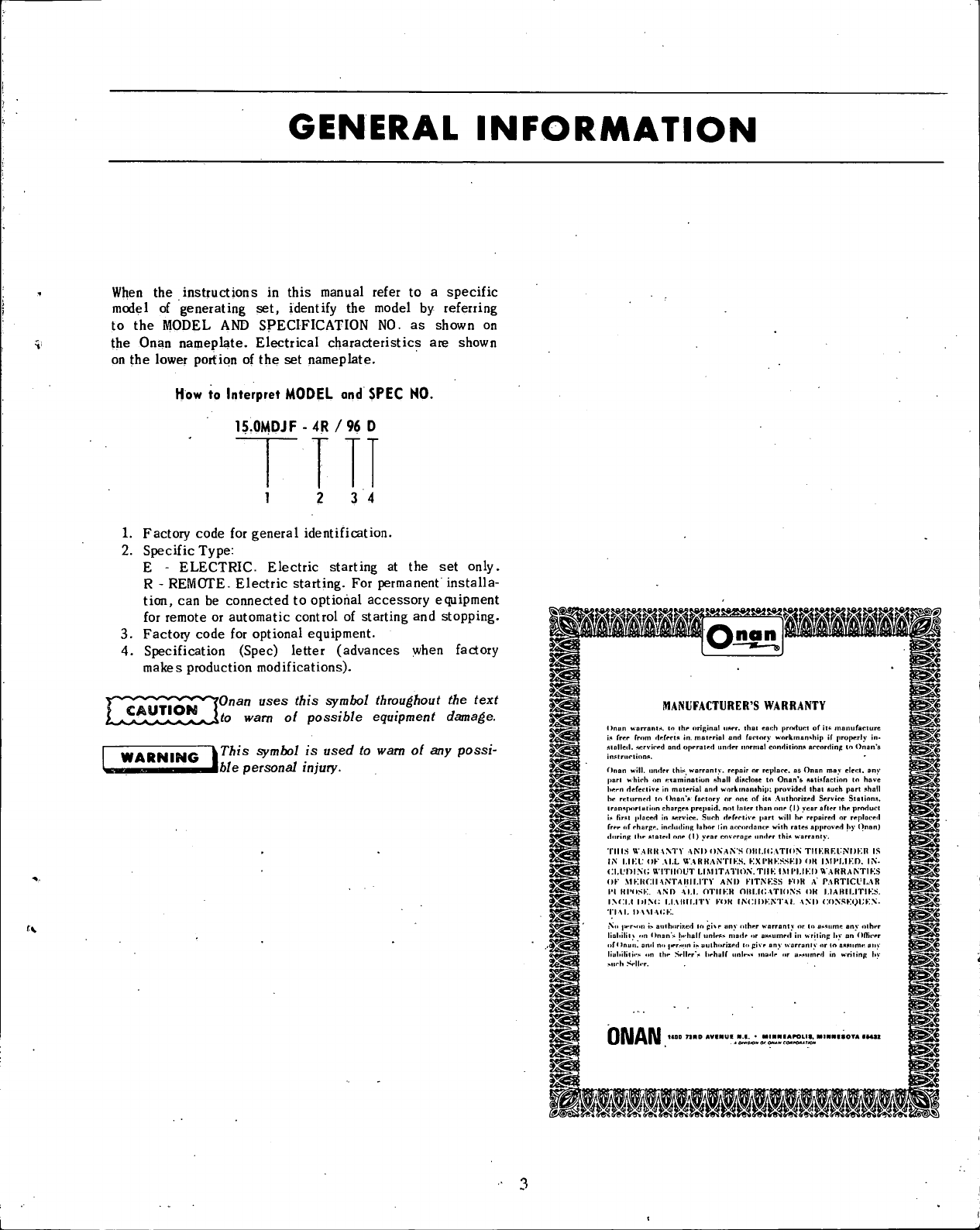

When

theinsttuctionsinthismanualrefertoa specific

modelofgeneratingset,identifythemodelbyreferring

tothe

MODEL

AND

SPECIFICATION

NO.asshownon

the

Onan

nameplate.

Electrical

characteristicsareshown

onthelowerportionofthesetnameplate.

How

to

Interpret

MODEL

and

SPEC

NO.

15

OMDJ

F

- 4R/

96

D

1 3

4

1.Factory

code

forgeneralidentification.

2.

Specific

Type:

E

-

ELECTRIC.

Electric

startingatthesetonly.

R

-

REMOTE.

Electric

starting.Forpermanentinstalla-

tion,canbeconnectedtooptionalaccessoryequipment

forremoteorautomaticcontrolofstartingandstopping.

3.

Factory

code

foroptionalequipment.

4.Specification(Spec)letter(advanceswhenfactory

makesproductionmodifications).

CAUTION

'Onan uses this symbol throughout

the

text

to warn

ol

possible equipment damage.

WARNING

|^"ssym^'s

used

to

warn

ol any

possi-

H^HHMBBi^J&/e personal injury.

MANUFACTURER'S

WARRANTY

Onanwarrants.Inihe

nrigmal

iiAt-r.

thaitar.bproductofitnma

mi

fact

u

is

frrr

frnm

drfwlft

in.

motrriol

onH

fnrlory

workmanshipifproperlyin*

siollcil.

servicedandoperatedundernormalconditionsaccordingto

Onan's

inplrnrlinno.

Onan

will,

underthis

worrnnty.

repairnrreplace,asOnanmayelect,any

pan

which

onexamination

nhall

diocloaeto

Onan's

fintisfaction

lohove

hern

defeciiveinmaterialandworkmanship:providedlhatsuchpart

.ihall

hereturnedto

Onan's

factoryoroneofitsAuthorizedServiceSta

linns,

ironsporluiion

charges

prepaid,not

hiler

thanone

f

I)

yearaflertheproduci

if

first

placedin

wrvic*.

Suchdefectivepart

will

herepairedorreplaced

freeofcharpe,

including

lahor(in

accordance

wilh

rates

approvedhyOnon)

during

ihestatedone(1)yearcoverageunder

thin

warranly.

THIS

WARRANTY

AM)

ON.AN'S

OII

LIGATION

TMKRF.l'NDK.H

IS

IN

l.l

KL.'

OKALL

VIARK.ANTIK.S.

KX

I'H

KSSK.I)

OK

I.MPUKO.

IN-

<XUr>l.N(;

WITHOUT

LIMITATION.THK

IMIMJKI)

W.ARRANTIKS

OK

MKRCIIANTAIIIUTY

AND

K

ITN

KSS

KOHA

PARTICULAR

I'l

HI'O.SK.

ANOAM.

OTIIKH

OIII.I<;ATIONS

OR

I.1ABILITIKS.

I.NCI.I

IHN<;

LIAHILITY

KOK

INCIDKNTAI.

AND

CONSKQt'KN-

TIM.

DAM

ACK.

No

]MTMin

i>aulhoriiedlopi\eanyotherwarrantyorloa*<iumeany

olhei

lialiililt

on

Onan's

(..-half

unh-**

made

ora

KM

u

med'

in

wrilinp

hyan

fKhr.

of

*

Inuu.

amino

jiernon

ii>

uulhorizediopiveanvwarranlvoi

liuhililies

..niheSeller's

l.ehalf

unle«

made'ora^nmedin

writinp

hy

>urh

Sell.

r.

ONAN