TABLE

OF

CONTENTS

SUBJECT

Description

General

Data~,-

- - - - - - - - - - - -

~

- - - - - - - -

Engine - - - - - - - - - - - - - - - - - - - - - - - - -

Generator - - - - - - - - - - - - - -

--

- - - - - - - -

Controls

-Acee~sories

-.-

-

--

- - - - - - - - - - -

--

Installation

Location - - - - - - - - - - - - - - - - - - - - -

Ventilation

- - - - - - - - - - - - - - - - - - - - - - -

Fuel Supply -

Gasoline--

Gas

or

Vapor - - - - - -

--

- -

Batteries

- - - - - - - - - - - - - - - - - - - - - - - -

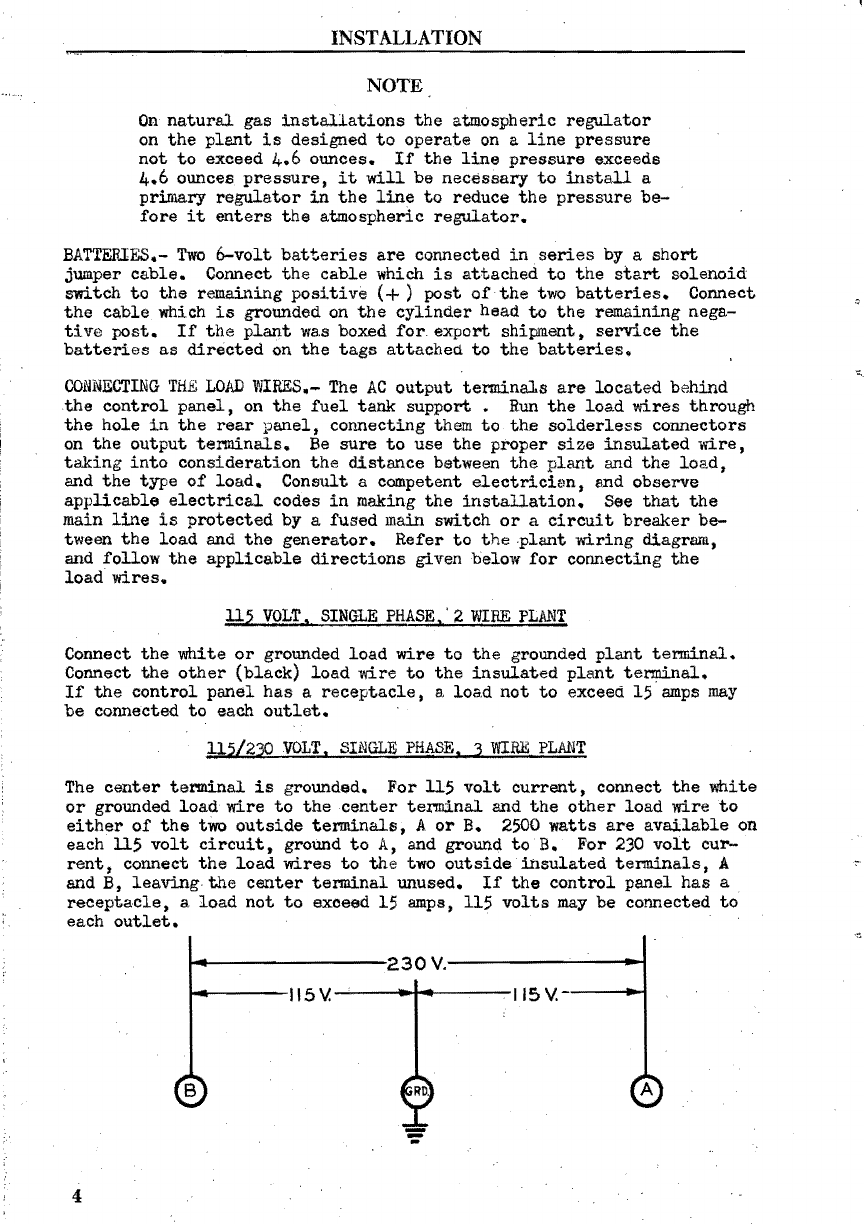

Connecting

the

Load Wires - - - - - - - - - - - - - - - -

Preparation

Lubrication

- - - - - - - - - - - - - - - - - - - - - - -

Fuel,

Gasoline -

Natural

Gas

or

LPG

- - - - - - - - - - -

Radiator

-

-:-

- - - - - - - - - - - -

.,.

- - - - - - -

Operation

Preliminary

- - - - - - - - - - - - - - - - - - - - - - -

Starting

the

Plant

Electrically

- - - -

--

- - - - -

--

starting

the

Plant

Manually - - - - - - - - - - - - - - -

Checking

the

Operation - - - - - - - - - - - - - - - - - -

stopping

the

Plant

- - - - - - - - -

--

- - - - - - - - -

Abno~al

Operating Conditions

Low

Temperatures - - - - - - -

-'-

- - - - - - - - -

---

High Temperatures - - - - - - - - - - - - - - - - - - - -

Dust and

Dirt

- - - - - - - - - - - - - - - - - - - - - -

Periodic

Service

Daily ,Service - - -

-.-

- - - - - - - -

--

- - - - - - -

Weekly

Service-

- - - - - - - - - - - - - - - - - - - - -

Monthly

Service

--

- -

-,-

- - - - - - - - - - - - - - -

Six

Monthly

Service

- - - - - - - - - - - - _

---

Adjustments

Carburetor,

Gasoline -

Carburetor,

Gas

or

Vapor -----

Electric

Choke

-Sisson

Choke

- - - - - -

~

- - - - - - -

Governor - - - - - - - - - - - - - - - - - - - - - - - -

High

Water Temperature Switch - - - - - -

'-~

- - - -

--

Fan

Belt

Tension - - - - - - - - - - - - ...:- - - - - - - -

Kaintenance and Repair

Engine

--

- - - - - - - - - - - - - - - - - - - - - - - -

Table

Qf

Clearances - - - - - -

--

- - - - - - - - - - -

Generator - - - - - - - - - - - - - - - - - - - - - - - -

Controls - - - - - - - - - - - - - - -

~

- - - - - - - - -

Service

Diagnosis

Possible

Cause -

Remedy

- - - - - - - - - - - - - - - - -

Instructions

for

Ordering

Repair

Parts

- - - -

~

- - - - - -

Repair

Parts

List

- -

..:

- - -

.;..

- - - - - - - - - - - - - - -

Supplement

for

Direct

Curr~t

Plants

PAGE

NO.

1

',')

2

2

2

3

3

:3

4

4

7

8

,8

9

9

9

10

II

12

13

13

14

14

15

16

17

17

19

20

20

21

27

29

30

.31

39

52

67