5

GENERAL INSTALLATION & SERVICE WARNINGS

The control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments. There is a small

amount of “give” to properly connect the piping, but the filter is not designed to support the weight of the plumbing.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on

black O-rings, but is not necessary. Avoid any type of lubricants, including silicone, on red or clear lip seals.

Do not use pipe dope or other sealants on threads. Teflon® tape must be used on the threads of the 1" NPT inlet

and outlet, the brine line connection at the control valve, and on the threads for the drain line connection. Teflon®

tape is not used on the nut connections or caps because O-ring seals are used. The nuts and caps are designed to be

unscrewed or tightened by hand or with the special plastic Service Wrench, #CV3193-02. If necessary, pliers can be used

to unscrew the nut or cap. Do not use a pipe wrench to tighten nuts or caps. Do not place screwdriver in slots on

caps and/or tap with a hammer.

SITE REQUIREMENTS

• Water Pressure: 25-100 psi

• Water Temperature: 33-100°F (0.5-37.7°C)

• The tank should be on a firm level surface

1. This unit is equipped with a 1” NPT connection at the

bottom of the tank. This connection is for an optional

drain that may be used to rinse the cartridge filter

periodically. If this is installed, location of the tank to

the actual drain should be as close as possible. It is

highly recommended to install the optional drain for

servicing the unit.

CAUTION: If a drain is not used or

the installation makes this

unavailable, the 1” hole must be

plugged or water will flow from

this outlet.

2. Do not install any water filter with less than 10 feet of piping between its outlet and the inlet of a water heater.

3. Do not locate unit where it or its connections (including the drain) will ever be subjected to room temperatures

under 33°F.

4. Do not subject the tank to any vacuum as this may cause an “implosion” and could result in leaking. If there is a

possibility a vacuum could occur, please make provisions for a vacuum breaker in the installation.

5. INLET/OUTLET PLUMBING: Be sure to install bypass valve onto main control valve before beginning plumbing. Make

provisions to bypass any outside hydrant at this time. Install an inlet shutoff valve and plumb to the unit’s bypass

valve inlet located at the right rear as you face the unit. There are a variety of installation fittings available. They are

listed under the installation fitting assemblies section in this manual. When assembling the installation fitting package

(inlet and outlet), connect the fitting to the plumbing system first and then attach the nut, split ring, and O-ring.

Heat from soldering or solvent cements may damage the nut, split ring, or O-ring. Solder joints should be cool and

solvent cements should be set before installing the nut, split ring, and O-ring. Avoid getting solder flux, primer, and

solvent cement on any part of the O-ring, split rings, bypass valve, or control valve. If the building’s electrical system is

grounded to the plumbing, install a copper grounding strap from the inlet to the outlet pipe. Plumbing must be done

in accordance with all applicable local codes.

TYPICAL INSTALLATION

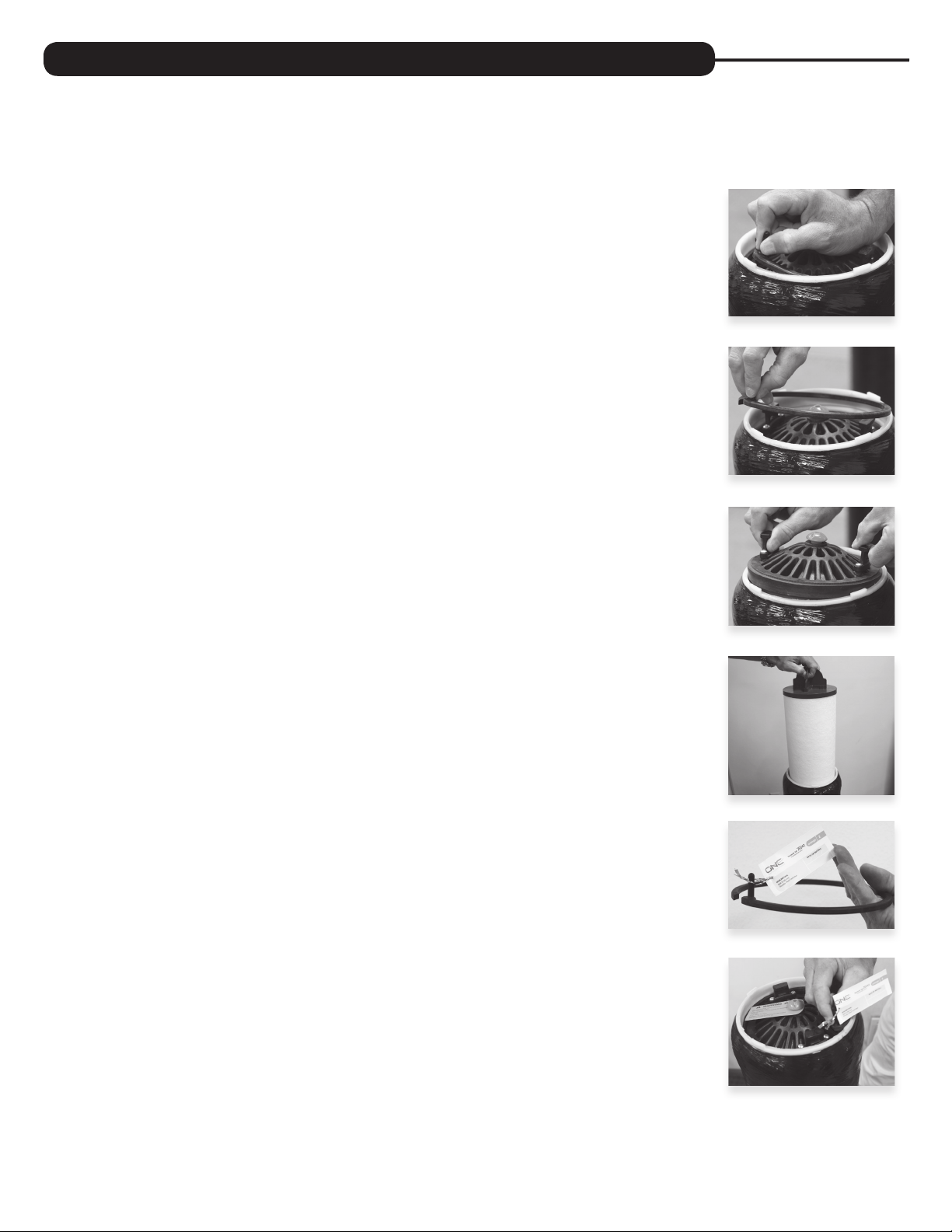

INSTALLATION INSTRUCTIONS FOR CW-840-1:

The larger of 2

pipe diameters

or 1” air gap

required