NT‐105v.1.0EN

2

ATTENTION!PLEASEREADTHISMANUALBEFOREUSINGTHESPRAYGUN(TOOL).

IMPROPEROFUSETOOLMAYCAUSEINJURYAND/ORPROPERTYDAMAGE!

ONLY QUALIFIED AND SPECIALLY TRAINED PERSONNEL FAMILIED WITH THESE INSTRUCTIONS IS ALLOWED TO USE AND

MAINTENANCEOFTHETOOL.

Thismanualcontainsdescription,safetyrulesandalltheinformationnecessaryforthecorrectuseofthespraygun.

Thesafetyadvicegiveninthismanualisinadditiontoanddoesnotreplacethegeneralsafetyregulationsapplicableinthe

regionwherethetoolisused.

Sprayedmaterials(paints,solvents,etc.)canbeharmfultohealth. Alwaysreadalllabels,safetydatasheets

andfollowalltherecommendationsforthematerialbeforespraying.Incaseofdoubts,contactyourmaterial

supplier.Theuseofrespiratoryprotectiveequipmentisalwaysrecommended.

Alwaysweareyeprotectionwhensprayingorcleaningthespraygun.

Glovesmustbewornduringsprayingorcleaningtheequipment.

Staticelectricitycanbegeneratedbyfluidand/orairpassingthroughhoses,bythesprayingprocessandby

cleaningnon‐conductivepartswithcloths.Topreventignitionsourcesfromstaticdischarges,earthcontinuity

mustbemaintainedtothespraygunandothermetallicequipmentused.Itisessentialtouseconductiveair

and/orfluidhoses.

Sparks,openflamesorhotsurfacescancreateafireorexplosion.

GENERALRULESOFOPERATION

Whenworkingwiththetoolalwaysusepersonalprotectiveequipmentappropriateforthetypeofworkperformed(goggles,

impactresistantglasses,handprotection,body,etc.);

Theemployee'sappearancemustcomplywithsafetyrequirements;

Usespraygunonlyforitsintendedpurpose;

Observegroundingrulesintheworkplace;

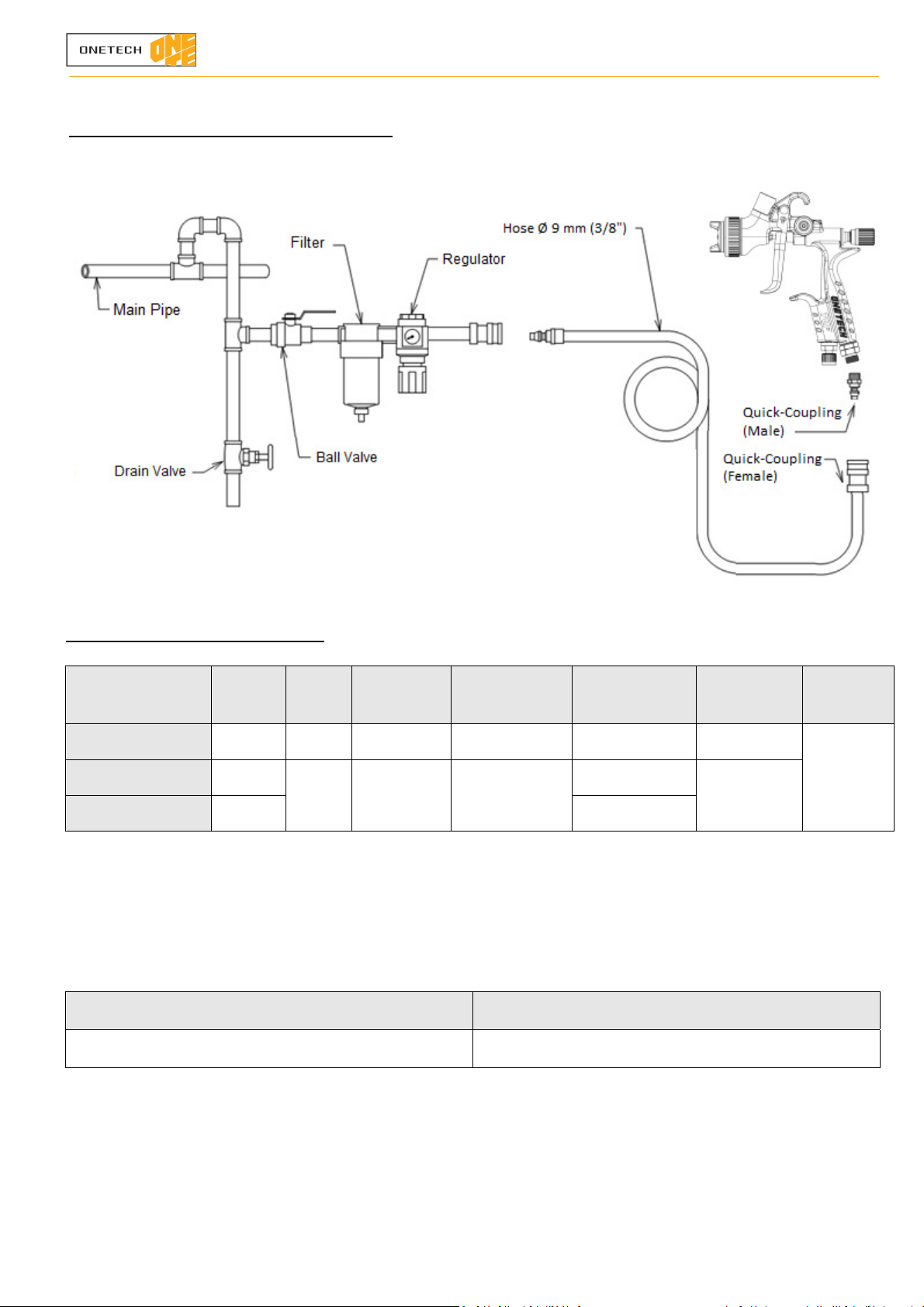

Toensuremaximumperformanceanddurabilityofthetool,theworkingpressureofthecompressedairmustmatchthe

spraytechnology;

Highnoiselevelscancausehearingloss.Timelymaintenancewillhelptoavoidnoiselevelsincrease;

Theflowofcompressedaircancauseseriousinjury.Neverdirectairflowtowardsyourselforothers.Donotusecompressed

airtocleanclothes;

Beforestartingwork,checkthecompressedairsupplyhosefordamage,wearorotherdefects.Replaceimmediatelyiffound;

Checkscrewconnectionsbeforestartingwork.Tightenifnecessary;

Donotcarrythetoolbythecompressedairsupplyhose;

Alwaysdisconnectthetoolfromthecompressedairlinebeforeperformingmaintenance;

Usematerialsandsolventsthatarecompatiblewiththespraygunparts.Donotusesolventsorproductscontainingacids;

Avoidprolongedexposuretosolventsonnon‐metallicpartsofthespraygun.

Flushspraygunbeforestartinguse,beforechangingmaterialsandattheendofwork.Donotusemethylenechloride1,1,1‐

trichloroethaneforflushing.Thesesolventscanchemicallyreactwithaluminumgunparts.