NT10-400G ENGLISH v.2.0

2

ATTENTION! PLEASE READ THIS MANUAL BEFORE USING THE SPRAY GUN (TOOL).

IMPROPER USE OF TOOL MAY CAUSE INJURY AND/OR PROPERTY DAMAGE!

ONLY QUALIFIED AND SPECIALLY TRAINED PERSONNEL FAMILIED WITH THESE INSTRUCTIONS IS ALLOWED TO USE AND

MAINTENANCE OF THE TOOL.

This manual contains description, safety rules and all the information necessary for the correct use of the spray gun.

The safety advice given in this manual is in addition to and does not replace the general safety regulations applicable in the

region where the tool is used.

➢Sprayed materials (paints, solvents, etc.) can be harmful to health. Always read all labels, safety data sheets

and follow any recommendations for the material before spraying. If in doubt, contact your material supplier.

The use of respiratory protective equipment is recommended at all times.

➢Always wear eye protection when spraying or cleaning the spray gun.

➢Gloves must be worn when spraying or cleaning the equipment.

➢Static electricity can be generated by fluid and/or air passing through hoses, by the spraying process and by

cleaning non-conductive parts with cloths. To prevent ignition sources from static discharges, earth continuity

must be maintained to the spray gun and other metallic equipment used. It is essential to use conductive air

and/or fluid hoses.

➢Sparks, open flames or hot surfaces can create a fire or explosion.

GENERAL RULES OF OPERATION

•When working with the tool always use personal protective equipment appropriate for the type of work performed (goggles,

impact resistant glasses, hand protection, body, etc.);

•The employee's appearance must comply with safety requirements;

•Use spray gun only for its intended purpose;

•Observe grounding rules in the workplace;

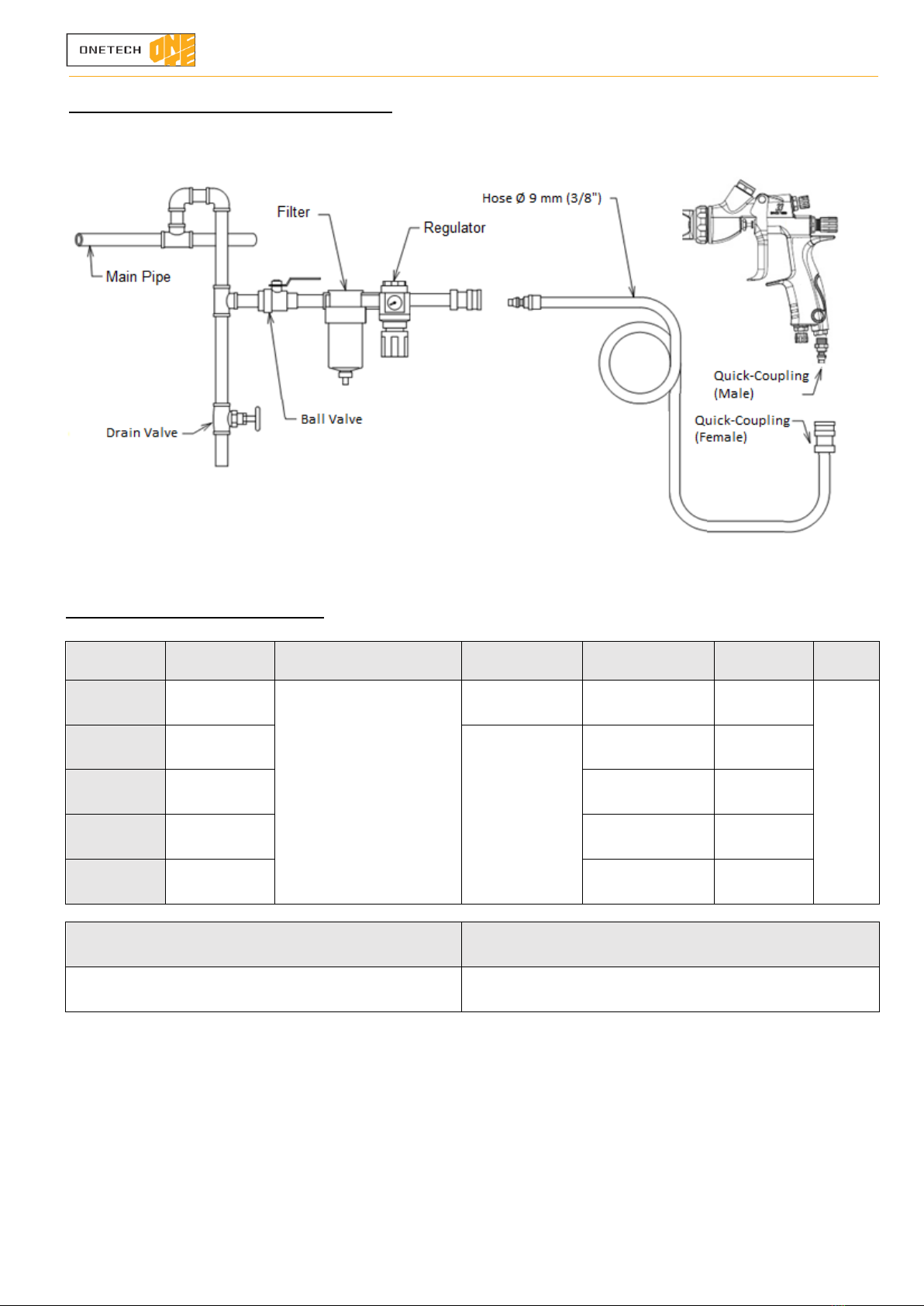

•To ensure maximum performance and durability of the tool, the working pressure of the compressed air must match the

spray technology;

•High noise levels can cause hearing loss. Timely maintenance will help avoid an increase in noise levels;

•The flow of compressed air can cause serious injury. Never direct the air flow towards yourself or others. Do not use

compressed air to clean clothes;

•Before starting work, check the compressed air supply hose for damage, wear or other defects. Replace immediately if found;

•Check screw connections before starting work. Tighten if necessary;

•Do not carry the tool by the compressed air supply hose;

•Always disconnect the tool from the compressed air line before performing maintenance;

•Use materials and solvents that are compatible with the spray gun parts. Do not use solvents or products containing acids;

•Avoid prolonged exposure to solvents on non-metallic parts of the spray gun.

•Flush spray gun before starting use, before changing materials and at the end of work. Do not use methylene chloride 1,1,1-

trichloroethane for flushing. These solvents can chemically react with aluminum gun parts.