1. PACKAGING

Following list of parts is included inside CS-503

package:

1. CS-503 cascade controller

2. 4 pcs of RS connection cable (5m)

3. 230V power supply cord

4. User manual

2. BASIC DESCRIPTION

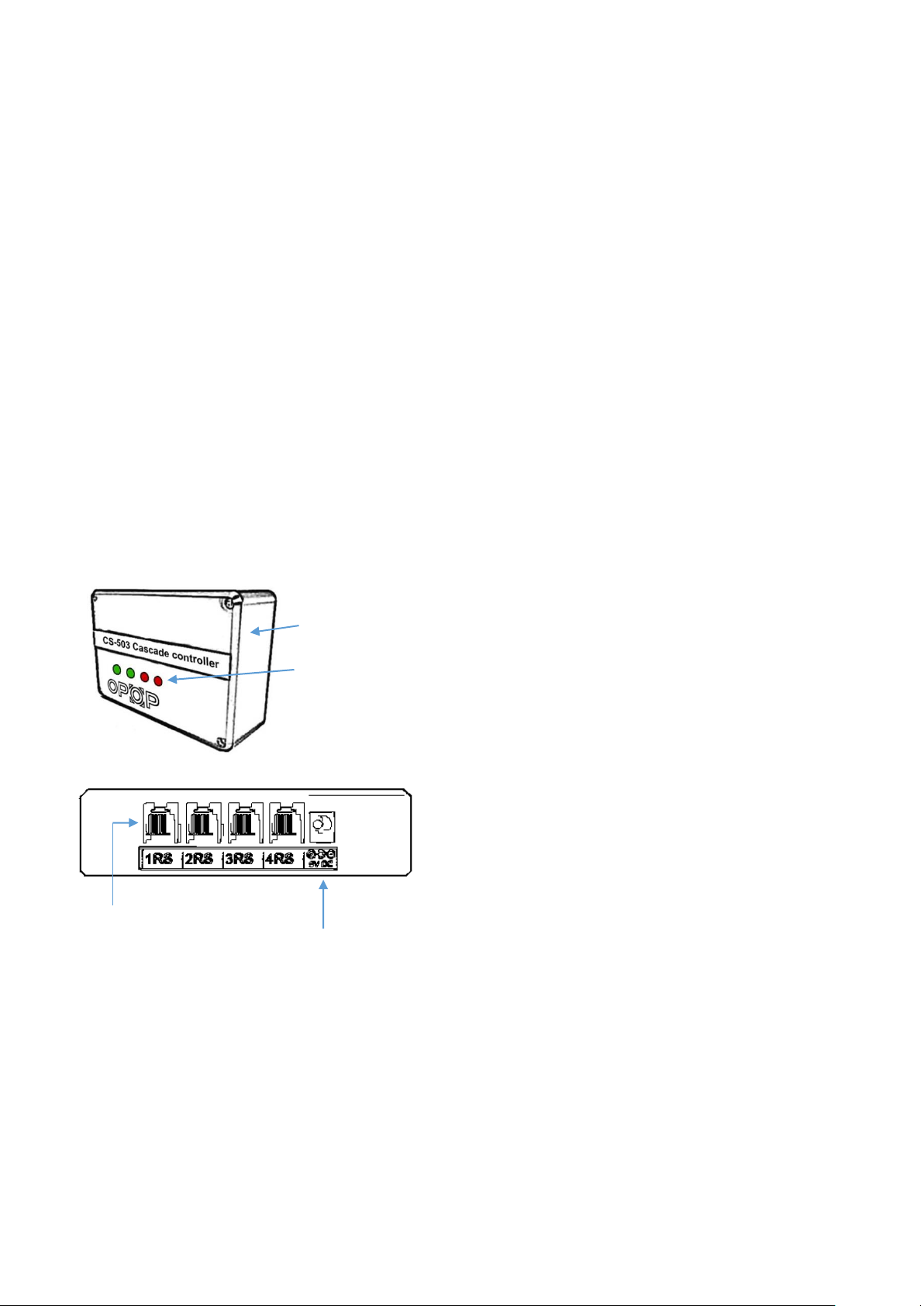

1. CS-503 controller

2. 4pcs of RS connectors,

for connection of each boiler enabling multi-

structural communication provided by cascade

controller.

3. Indication diodes,

which indicates real time boiler operation.

Light indicates that boiler is in operation, no

light indicates that boiler is turned off by

cascade controller.

4. Power supply cord,

to connect controller to the electricity.

Main box

Indication diodes

No light –boiler off

Light –boiler on

RS outputs for boiler connection

Power supply cable

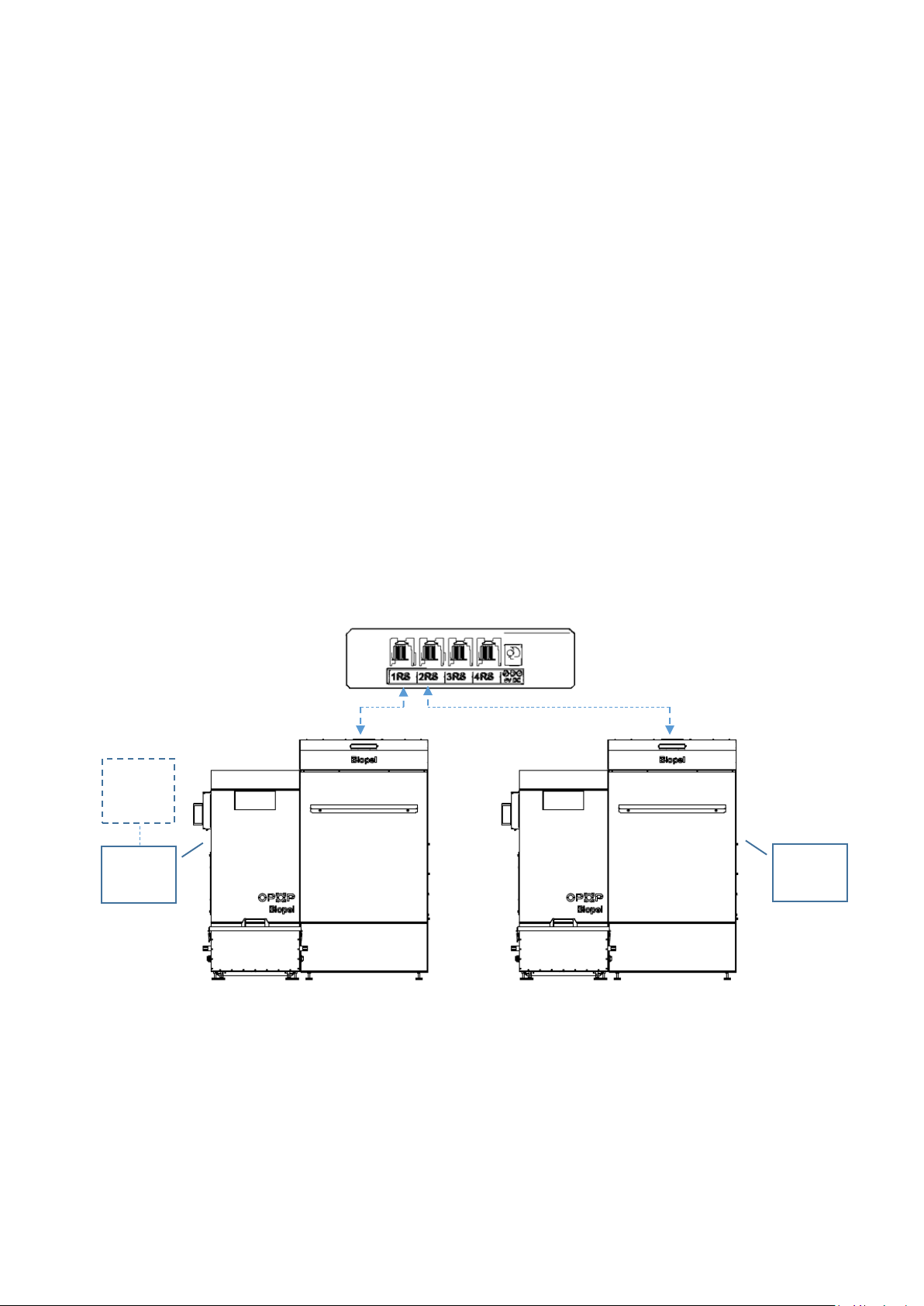

CS-503 cascade controller should be connected close

to the boilers to connect each of them with 5m RS cable

supplied in standard delivery.

Position all cables in a way to protect them against

physical and heat damage.

Device should not be installed close to other

electromagnetic devices such as motors, fans of the

boiler. Safe distance is at least 50cm.

3. TECHNICAL SPECIFICATION

Following list is specification of basic electrical and

other technical values.

Power supply 230V

Power consumption 1W

Maximal current 250mA

CS-503 diameters:

oHeight 20mm

oLength 100mm

oDepth 40mm

RS connection cable:

oLength 5m

oConnector RS

Max operational temp. -20 to 45°C

Package weight 35g

4. SAFETY REQUAREMENTS

Read these instructions carefully to make sure CS-503

will work without any problem in all conditions.

Do not install any kind of cascade controller

equipment directly on boiler or boiler

equipment surface to protect device and

cables against high temperatures.

Cables connecting each boiler should be

covered and positioned in a safe way, so no

heat ash or dust will damage them in long term

use.

Prevent installation of electronical

components in boiler rooms with high

humidity.

CS-503 cascade controller shouldn’t be

installed close to any kind of wireless or

electromagnetically operated device. Safe

distance is 50cm or more.

Update boiler control unit to the latest

firmware version to make sure cascade

operation is included in controller’s submenu.

Communicate the exact way of operation with

your installer to be sure cascade controller

operates all boilers in a way you need.

Consider both possible operations with CH

boiler temperature sensor and outside

Weather sensor.

Weather sensor is included in 431N module

packaging which is part of each burner box. To

make weather cascade operation work, also

431N module must be installed into the boiler

connected in 1st RS output of cascade

controller.