Duct Smoke Sensor KRM®

Fire Protection | Data sheet No. 41300 | Version 01-2011 | 1 | 8

Technical Data

Sensor: Scattering RM 3.3 (ALK-E)

Supply voltage KRM-1:

230 V AC ± 10 %, 50/60 Hz

Supply voltage KRM-2/KRM-2-MOD:

24 V AC/DC +15 % / -10 %

Rated current: KRM-1: 30 mA

KRM-2/KRM-2-MOD: 120 mA

Relay outputs: oating

Alarm relay locked: 1 changeover contact, 8 A,

250 V AC or 24 V DC

1 NC, 8 A, 250 V AC or 24 V DC

Contamination relay:

1 NC contact, 6 A, 250 V AC or 24 V DC

Operating temperature:

-10 °C - +50 °C

Permissible humidity:

10 - 95 % non-condensing

Protection class:

IP 54, IP 65 with WDG

(water resistant housing)

Approvals:

Sensing chamber and

air duct frames: VdS approval G210059

Tested:

according to FprEN54-27

LED display:

% contamination level ashes

at > 70 %

LED in housing:

green operating

blue lack of air ow

yellow failure, electronics,

smoke detector defective,

low voltage

red smoke alarm, including

contamination > 99 %,

ashes at attempts to release

when the sensing chamber is

not empty

Adaptergehäuse: ABS

Air measuring tube:

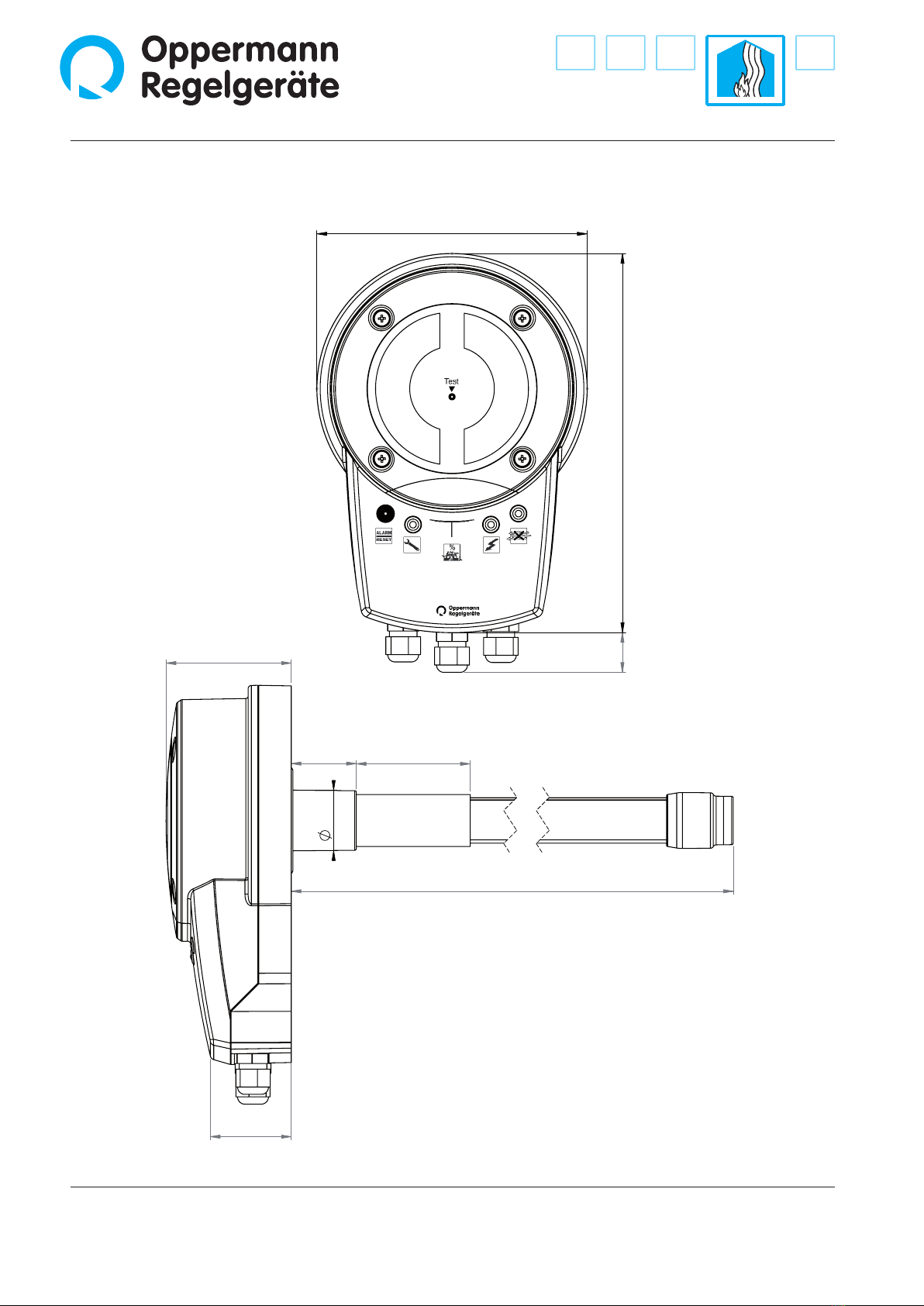

Aluminium / plastic

shortest length 160 mm

standard length 600 mm

Dimensions:

257 x 166 x 77 mm (L x W x H)

Screw connection:

3 x M16

• VdS certication (G210059)

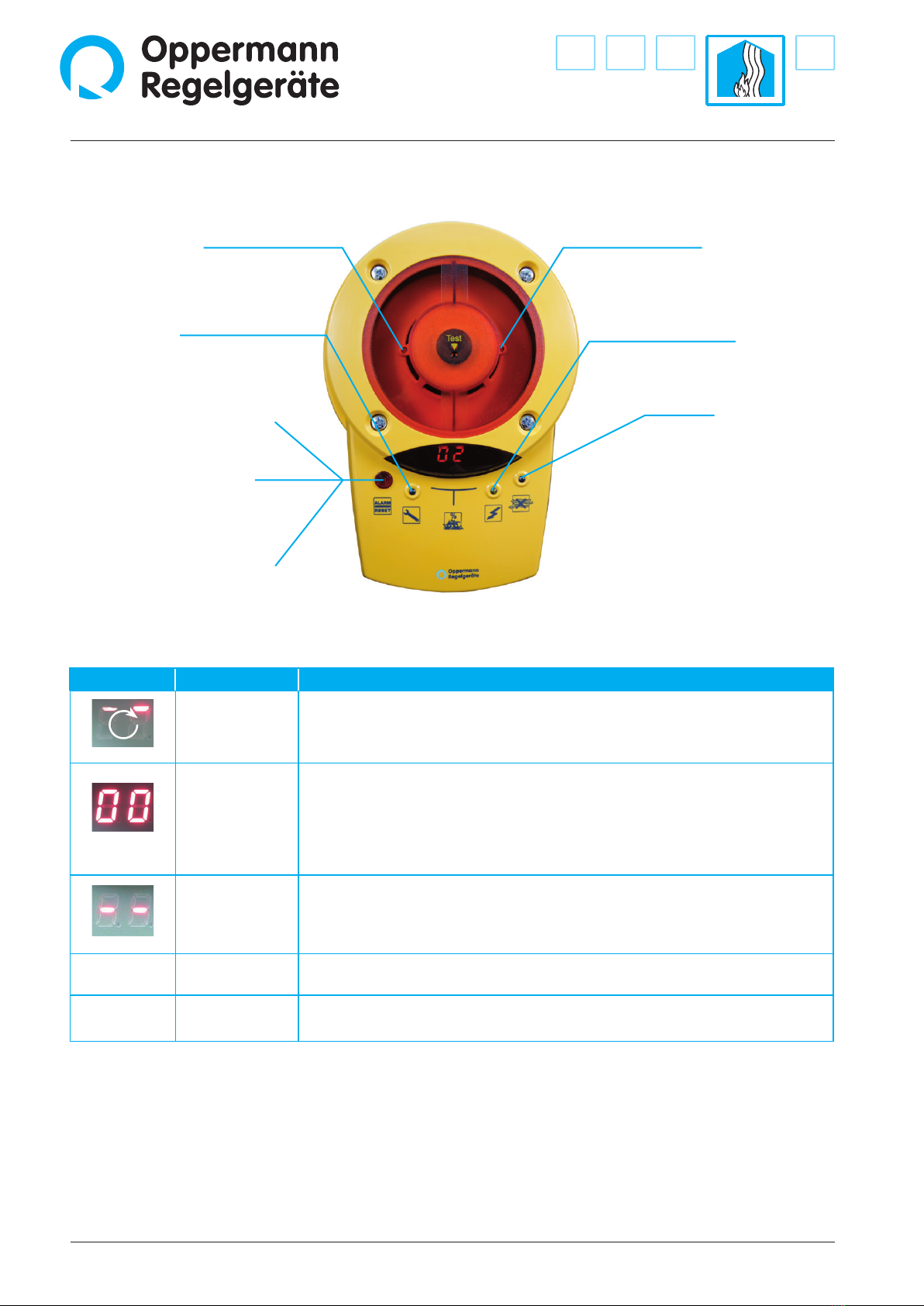

• Patented single tube air sampling system

• Contamination display in %

and signalling at 100 %

• Electronic air ow control

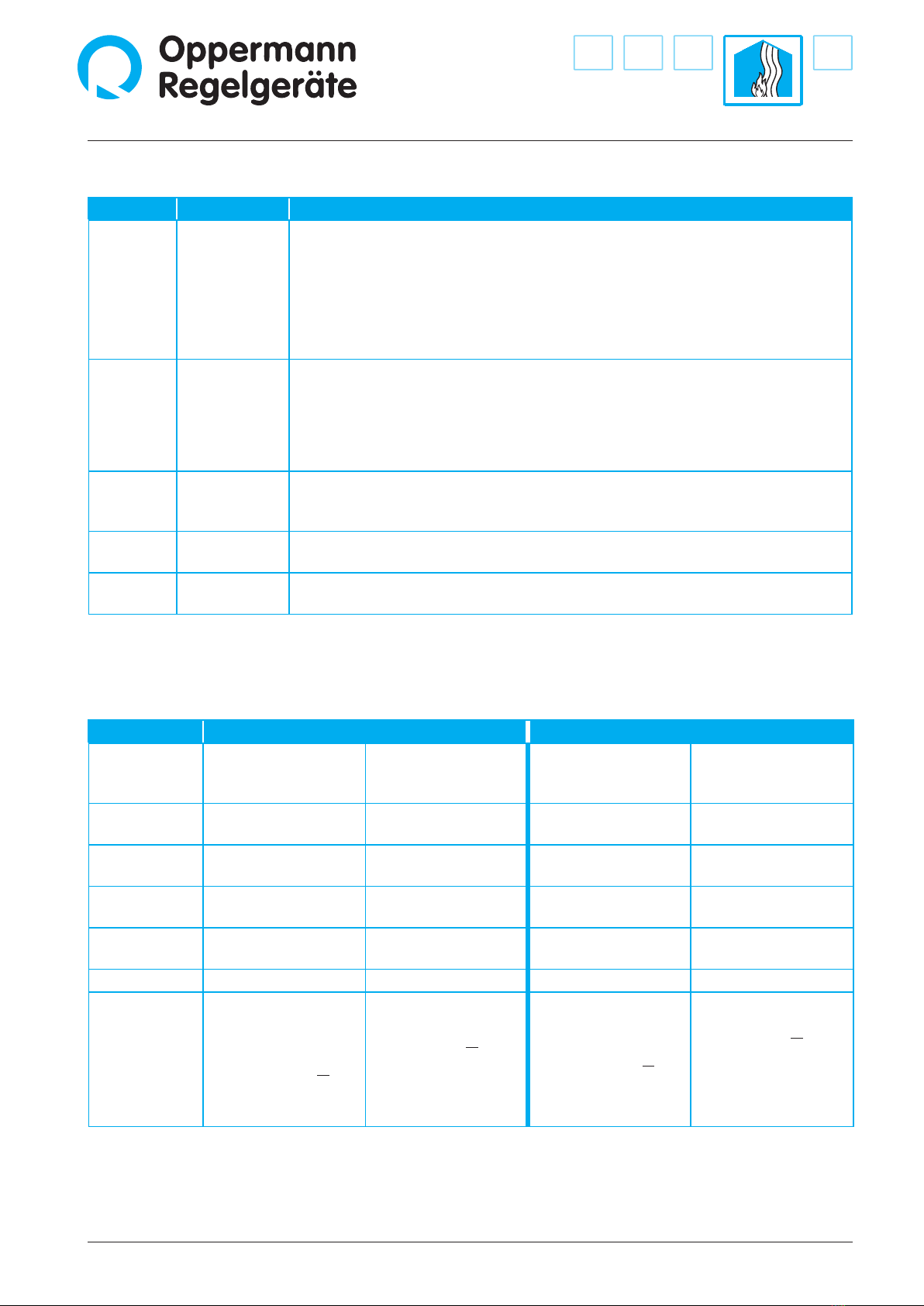

• Externally operable reset button in the

housing

• Remote reset option via terminals

• Long service life, low contamination

Accessories

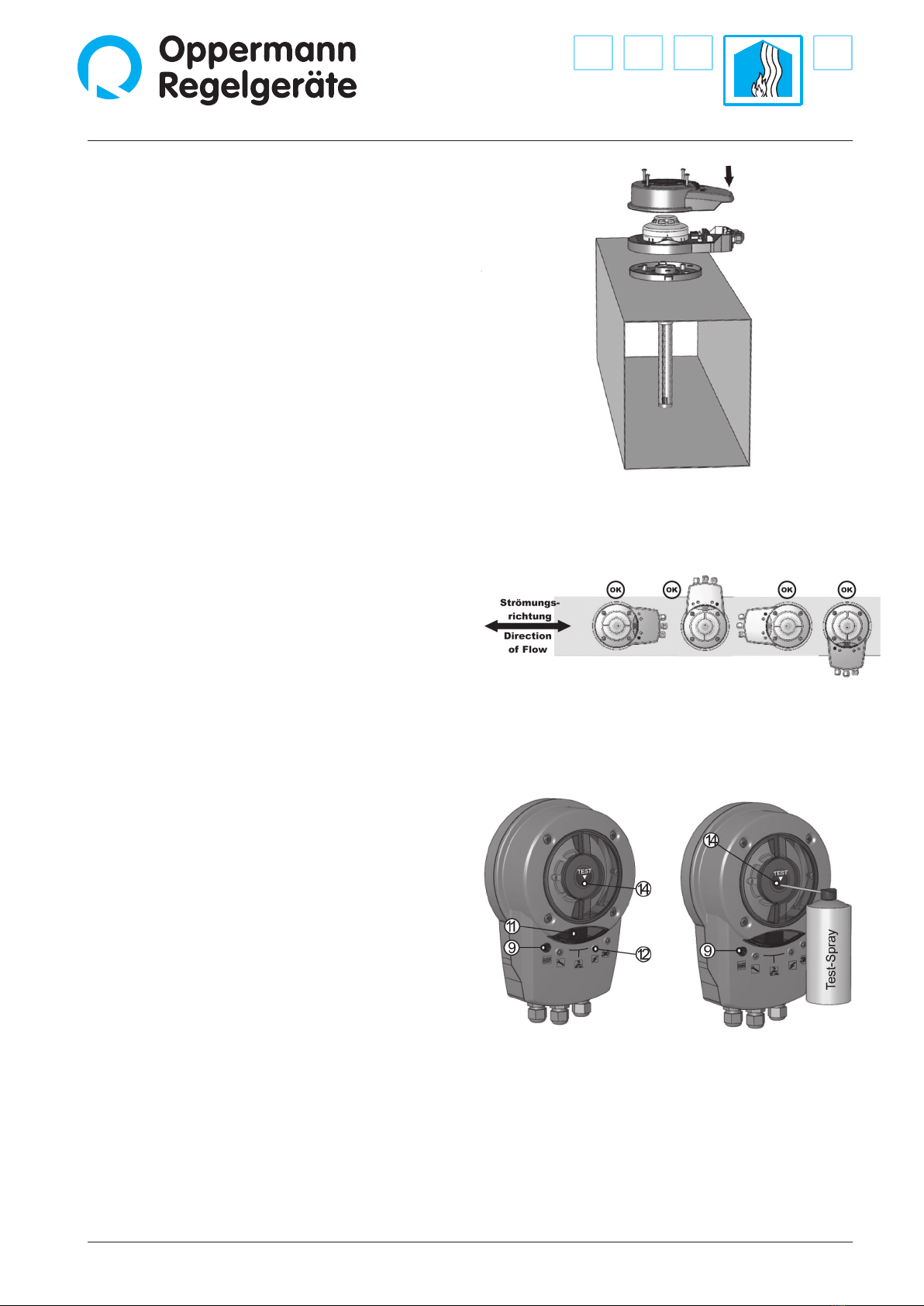

Mounting bracket: KS (for insulated / circular ducts)

Housing: waterresistant housing for outdoor

installation and increasing protection

class to IP 65

Function

The KRM duct smoke detector is designed for smoke detection

in ventilation ducts. It constitutes a combination of a smoke

detector with an adapter system, whose measuring tube and

housing have been specially adapted for optimal air ow through

the smoke detector.

The multi-chamber measuring tube in the air duct transports the

air within the air duct along the entire length of the tube, through

the sensing chamber and back into the air duct. Upon detection

of smoke, the sensor reacts immediately and triggers an alarm.

Over time, the sensor becomes contaminated. Because of alarm

threshold tracking, the sensitivity up to total pollution remains

the same. From 70 % contamination upwards, the sensor is trig-

gered and indicates this by ashing. If the sensor is not replaced

the smoke alarm is triggered at 99 % contamination.

The contamination level is indicated in a two-line LED display; at

> 70 % it ashes.

To verify operability, the device is equipped with electronic air

ow monitoring, which lights a blue LED at < 1 m/s. The failure

LED illuminates when the smoke sensor or the electronics are

defective, in the absence of a smoke sensor, and with short-

circuits or cable breakage.

The smoke alarm must be released with the reset button.

A functionality test is also possible with the same button.

The operation functions like a smoke alarm.

Furthermore, the same function takes place on restart or when

the bridge circuit between terminals 9 and 10 is opened (remote

release).