2| 2| Sensors PG1 | Data sheet No. 11102 | Version 08-2019 Specications subject to change.

Airow monitor SL 520 1.3A

Oppermann Regelgeräte GmbH | Im Spitzhau 1 | 70771 Leinfelden-Echterdingen, Germany

Phone +49 711 72723560 | Fax +49 711 7280527 | info@oprg.de | www.oprg.de

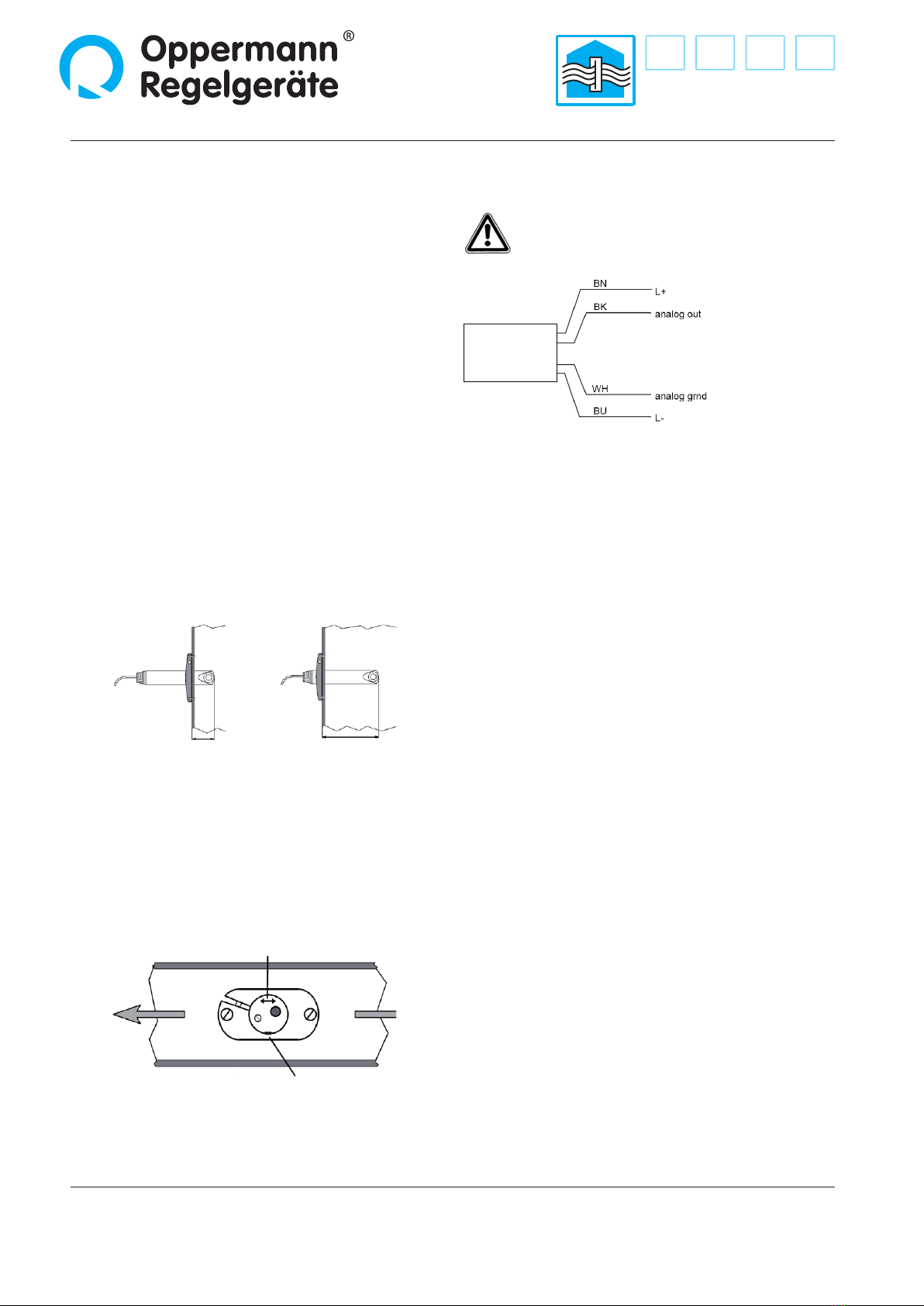

Arrow parallel to airow.

LED

Installation

Please observe these instructions. All work (such as installation,

electrical connection, startup, operation, and maintenance)

must only be performed by suciently qualied tradesmen. The

respectively applicable local rules and regulations (e.g. national

building codes, electrical/VDE regulations, etc.) must be observed.

Installers and operators are required to suciently familiarize

themselves before startup. Read the product description before

operating the equipment. Verify that the product can be used for

the relevant application without restrictions. We are not liable for

printing errors and changes after printing. Appropriate use implies

compliance with operating and installation instructions. We are

not liable for losses due to inappropriate use. Unauthorized or

inappropriate manipulations or modications of the device render

the operating permit, the product warranty and warranty claims

null and void.

The installation length of the sensor supports a maximum

probe depth of 115 mm into the air duct. The unit is installed

with the included installation clamp, which is attached to the air

duct with two sheetmetal screws. A mark on the sensor housing

ensures proper alignment with the ow.

min. 34 mm max. 115 mm

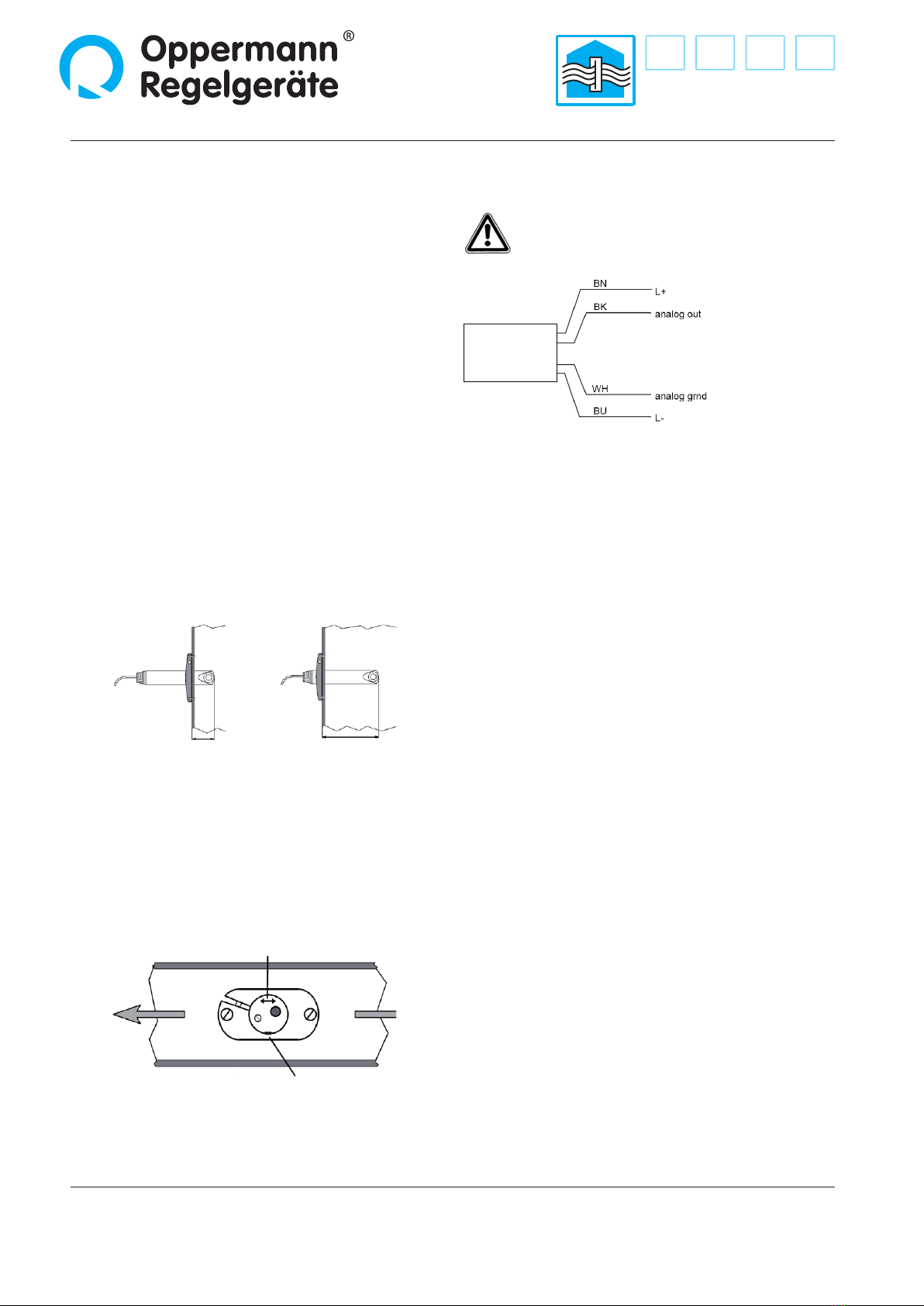

Electrical connection

Disconnect the system from power. Connect the sensor

as indicated on the type tag.

Operation

Verify reliable operation of the device. The green LED is on

when the power supply is on. The unit is operational approx. 90

s after the power supply is switched on. The output is tuned for

the measured value during the startup time of 90 s, after which

a stable sensor signal is available.

Core colors:

BN brown

BU blue

BK black

WH white

The airow monitor is clamped with the installation clamp. The

diameter of the bore in the air duct is 23 mm. The included foam

rubber gasket is placed between the duct and the installation

clamp as an air-tight seal. The sensor head must reach at least 34

mm (max. 115 mm) into the duct and be located within the zone

of maximum ow velocity. Avoid turbulence zones (clearance to

interfering elements 5xD upstream of sensor, 3xD downstream of

sensor).

Align the device with the airow. The arrow marked on the plug

must point in the direction of airow.