Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 Disassembly flow chart ......................................................... 1-1

1.2 How to read the disassembly and assembly ......................... 1-1

1.3 Disassembly/assembly method ............................................ 1-1

1.4 Service position ..................................................................... 1-4

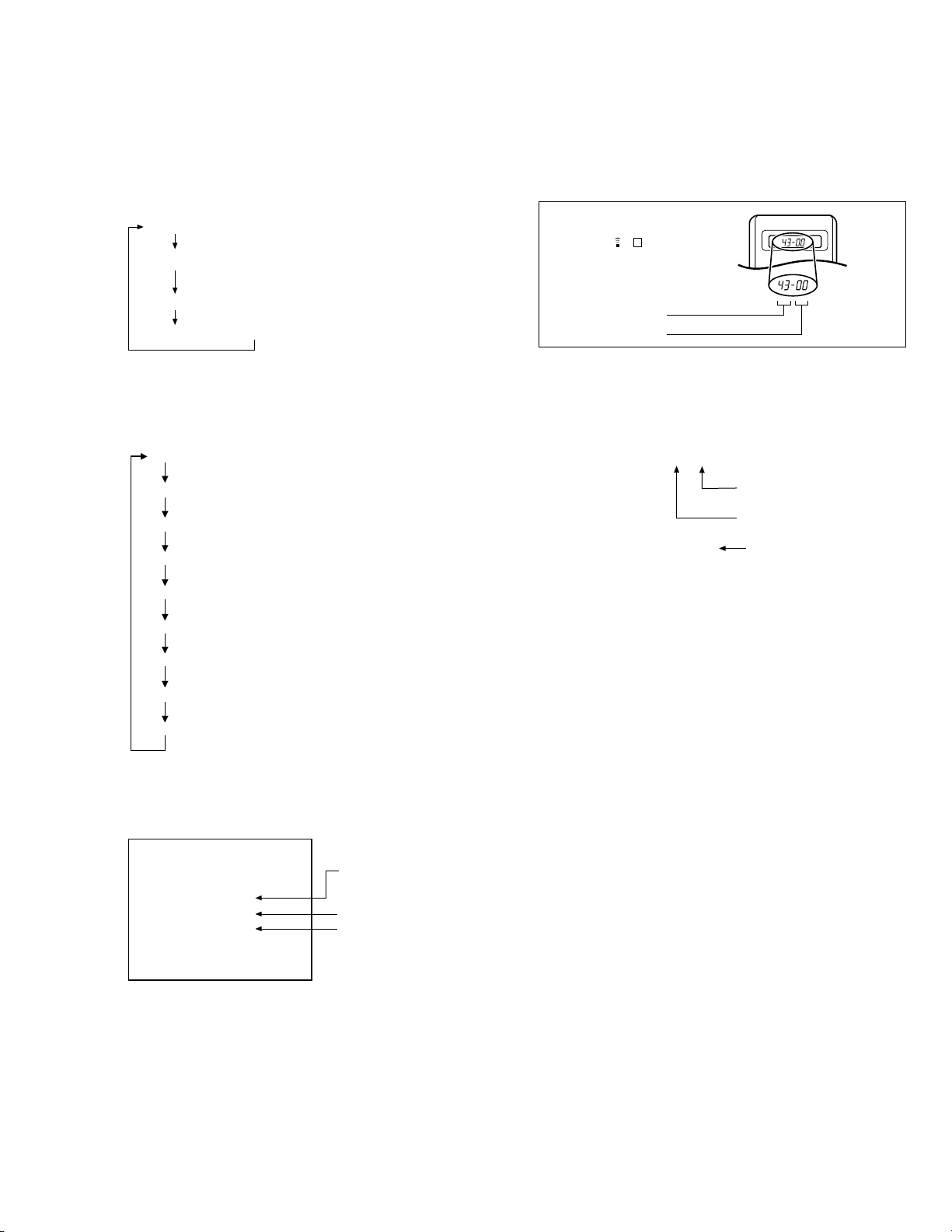

1.4.1 How to set the “Service position” .................................... 1-4

1.5 Mechanism service mode ..................................................... 1-4

1.5.1 How to set the “Mechanism service mode” .................... 1-4

1.6 Jig RCU mode ....................................................................... 1-4

1.6.1 Setting the Jig RCU mode .............................................. 1-4

1.6.2 Setting the User RCU mode ........................................... 1-4

1.7 Emergency display function .................................................. 1-5

1.7.1 Displaying the EMG information ..................................... 1-5

1.7.2 Clearing the EMG history ............................................... 1-5

1.7.3 EMG content description ................................................ 1-6

1.7.4 EMG detail information <1> ............................................ 1-7

1.7.5 EMG detail information <2> ............................................ 1-8

2. MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment .................................. 2-1

2.1.1 Precautions ..................................................................... 2-1

2.1.2 Checking for proper mechanical operations ................... 2-1

2.1.3 Manually removing the cassette tape ............................. 2-1

2.1.4 Jigs and tools required for adjustment ............................ 2-2

2.1.5 Maintenance and inspection ........................................... 2-3

2.2 Replacement of major parts .................................................. 2-6

2.2.1 Before starting disassembling (Phase matching between

mechanical parts) .......................................................... 2-6

2.2.2 How to set the “Mechanism assembling mode” .............. 2-6

2.2.3 Cassette holder assembly .............................................. 2-6

2.2.4 Pinch roller arm assembly .............................................. 2-8

2.2.5 Guide arm assembly and press lever assembly ............. 2-8

2.2.6 A/C head ......................................................................... 2-8

2.2.7 Loading motor ................................................................. 2-8

2.2.8 Capstan motor ................................................................ 2-9

2.2.9 Pole base assembly (supply or take-up side) ................. 2-9

2.2.10 Rotary encoder ........................................................... 2-10

2.2.11 Clutch unit ................................................................... 2-10

2.2.12 Change lever assembly, direct gear, clutch gear and

coupling gear .............................................................. 2-10

2.2.13 Link lever ..................................................................... 2-11

2.2.14 Cassette gear, control cam and worm gear ................. 2-11

2.2.15 Control plate ................................................................ 2-11

2.2.16 Loading arm gear (supply or take-up side) and

loading arm gear shaft ................................................ 2-12

2.2.17 Take-up lever, take-up head and control plate guide .. 2-13

2.2.18 Capstan brake assembly ............................................ 2-13

2.2.19 Sub brake assembly (take-up side) ............................ 2-13

2.2.20

Main brake assembly (take-up side), reel disk

(take-up side) and main brake assembly (supply side)....

2-13

2.2.21 Tension brake assembly, reel disk (supply side) and

tension arm assembly ................................................. 2-14

2.2.22 Idler lever, idler arm assembly .................................... 2-14

2.2.23 Stator assembly .......................................................... 2-14

TABLE OF CONTENTS

Section Title Page Section Title Page

2.2.24 Rotor assembly ........................................................... 2-14

2.2.25 Upper drum assembly ................................................. 2-15

2.3 Compatibility adjustment ..................................................... 2-16

2.3.1 FM waveform linearity .................................................. 2-16

2.3.2 Height and tilt of the A/C head ...................................... 2-17

2.3.3 A/C head phase (X-value) ............................................ 2-17

2.3.4 Standard tracking preset .............................................. 2-18

2.3.5 Tension pole position .................................................... 2-18

3. ELECTRICAL ADJUSTMENT

3.1 Precaution ............................................................................. 3-1

3.1.1 Required test equipments .............................................. 3-1

3.1.2 Required adjustment tools .............................................. 3-1

3.1.3 Color (colour) bar signal, color (colour) bar pattern ........ 3-1

3.1.4 Switch settings and standard precautions ...................... 3-1

3.2 Servo circuit .......................................................................... 3-2

3.2.1 Switching point ............................................................... 3-2

3.2.2 Slow tracking preset ....................................................... 3-2

3.3 Video circuit........................................................................... 3-2

3.3.1 Auto picture initial setting ................................................ 3-2

3.4 Demodulator circuit ............................................................... 3-2

3.4.1 Separation ...................................................................... 3-2

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .......................................... 4-1

CIRCUIT BOARD NOTES ........................................................... 4-2

4.1 BOARD INTERCONNECTIONS ........................................... 4-3

4.2 MAIN (VIDEO/AUDIO) SCHEMATIC DIAGRAM .................. 4-5

4.3 MAIN (SYSCON) SCHEMATIC DIAGRAM ........................... 4-7

4.4 MAIN (SW. REG) SCHEMATIC DIAGRAM........................... 4-9

4.5 MAIN (TUNER) SCHEMATIC DIAGRAM .............................4-11

4.6 MAIN (FMA/DEMOD) SCHEMATIC DIAGRAM .................. 4-13

4.7

MAIN (FRONT) AND MINI FRONT SCHEMATIC DIAGRAMS .

4-15

4.8 MAIN (TERMINAL) SCHEMATIC DIAGRAM ...................... 4-17

4.9 ADV. JOG SCHEMATIC DIAGRAM [HR-VP790U] ............. 4-18

4.10 CONNECTION SCHEMATIC DIAGRAM ........................ 4-19

4.11 MAIN CIRCUIT BOARD .................................................. 4-21

4.12 REMOTE CONTROLLER SCHEMATIC DIAGRAM ....... 4-24

4.13 FDP GRID ASSIGNMENT AND ANODE CONNECTION 4-25

4.14 WAVEFORMS ................................................................. 4-26

4.15 VOLTAGE CHARTS ........................................................ 4-27

4.16 CPU PIN FUNCTION ...................................................... 4-28

4.17 SYSTEM CONTROL BLOCK DIAGRAM ........................ 4-29

4.18 VIDEO BLOCK DIAGRAM .............................................. 4-31

4.19 AUDIO BLOCK DIAGRAM .............................................. 4-33

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ............... 5-1

5.2 FINAL ASSEMBLY <M2> ..................................................... 5-2

5.3 MECHANISM ASSEMBLY <M4> ......................................... 5-4

5.4 ELECTRICAL PARTS LIST ................................................... 5-6

MAIN BOARD ASSEMBLY <03> ............................................... 5-6

A/C HEAD BOARD ASSEMBLY <12> ...................................... 5-11

MINI FRONT BOARD ASSEEMBLY(HR-VP690U/U(C))<28> .5-11

ADV.JOG BOARD ASSEEMBLY(HR-VP790U/U(C))<38> .......5-11

LOADING MOTOR BOARD ASSEMBLY <55> ........................5-11

C.BOX/R.PAUSE BOARD ASSEMBLY(HR-VP790U/U(C)<99> ...

5-11

The following table lists the differing points between Models (HR-VP690U/U(C) and HR-VP790U/U(C)) in this series.

HR-VP690U/U(C) HR-VP790U/U(C)

JOG/SHUTTLE NOT USED USED

FOOT LINE – GOLD

REAR VIDEO/AUDIO IN NOT USED USED

VCR PLUS+ VCR+ VCR+ C3

REC LINK/INPUT NOT USED USED/L1

CABLE BOX OR DBS.BOX OR SAT CTL

NOT USED USED

PAUSE/AV COMPU TERMINAL NOT USED USED

CABLE MOUSE TERMINAL NOT USED USED

CABLE MOUSE NOT USED COUPON