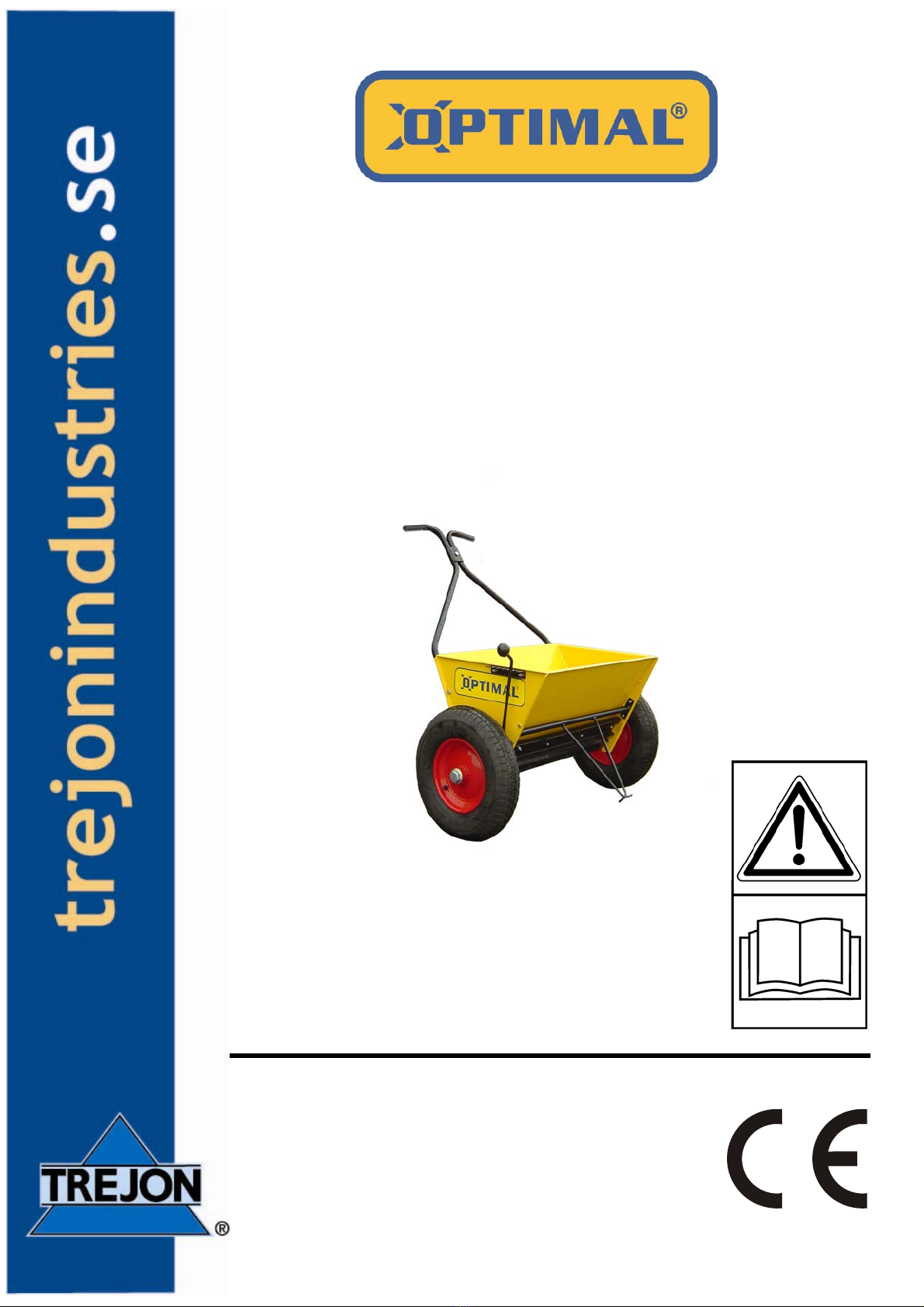

Instructions for Use and maintenance OPTIMAL SP50 (0810)

2 Safety instructions

2.1 Safety directions

Read this user manual and the safety directions carefully before using the equipment for

the first time.

Erroneous or negligent use of this equipment can lead to serious accidents. This equipment

is only for outdoor use.

•Read and understand the contents of this manual on the use of this equipment.

•Learn and practice the controls and the way the equipment works before using it.

•Let the machine work by itself; do not try to help using your fingers or hands.

•Check, adjust and maintain the equipment according to this manual.

•To maintain and adjust this equipment, it must be placed on a firm, level surface.

•Take care that arms or legs do not touch the moving parts of the equipment.

•Make sure that all protective parts are properly in place and that they are in good

condition.

•When working in the dark hours, make sure there is sufficient lighting in the working

area.

•Do not use the equipment if it is vibrating or shaking. Stop and investigate the

cause. Change any damaged parts.

Attention also has to be paid to the following:

•You may not transport people on the equipment.

•Unauthorized persons, particularly children, may not stay in the proximity of

equipment that is working or being repaired.

•Persons under the influence of alcohol or drugs are prohibited to work with the

equipment.

•It is forbidden to work with this equipment if the protections for the moving parts or

axles are missing.

•Be careful when working on uneven ground, reduce speed.

•Clean the equipment carefully before you repair it or put it away.

•Protect bearings before any welding is done.

Use only original spare parts for the equipment.

If you have any questions about the equipment or how it works, contact your retailer or

TREJON AB

TREJON AB - 6 - trejonindustries.se