I

Content

I. Safety Hints ...................................................................................................................................1

II. Overview ......................................................................................................................................2

2.1 Introduction.........................................................................................................................2

2.2 Index Parameters.................................................................................................................2

III. Composition................................................................................................................................3

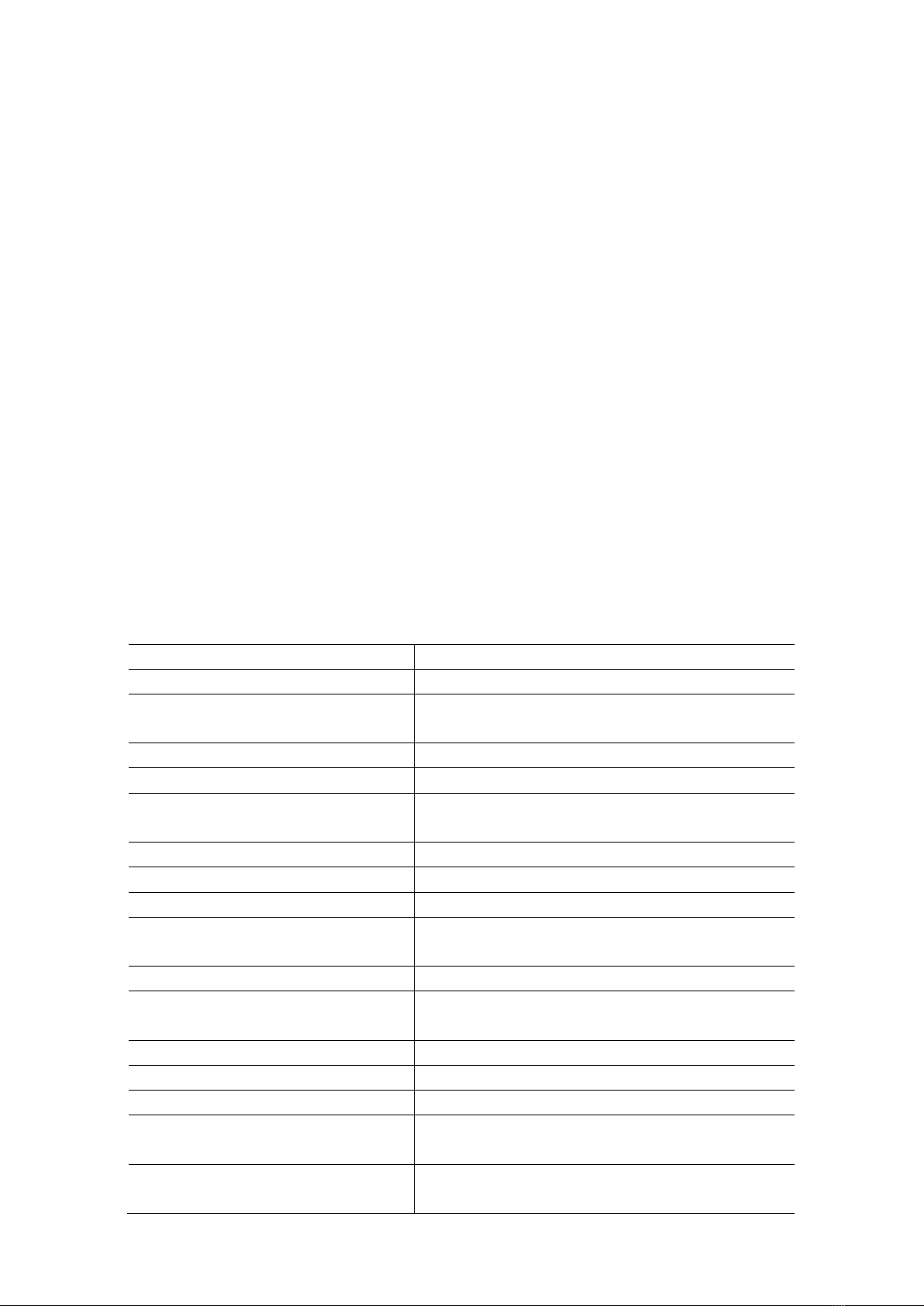

3.1 Appearance of the Mainframe and Its Components.........................................................3

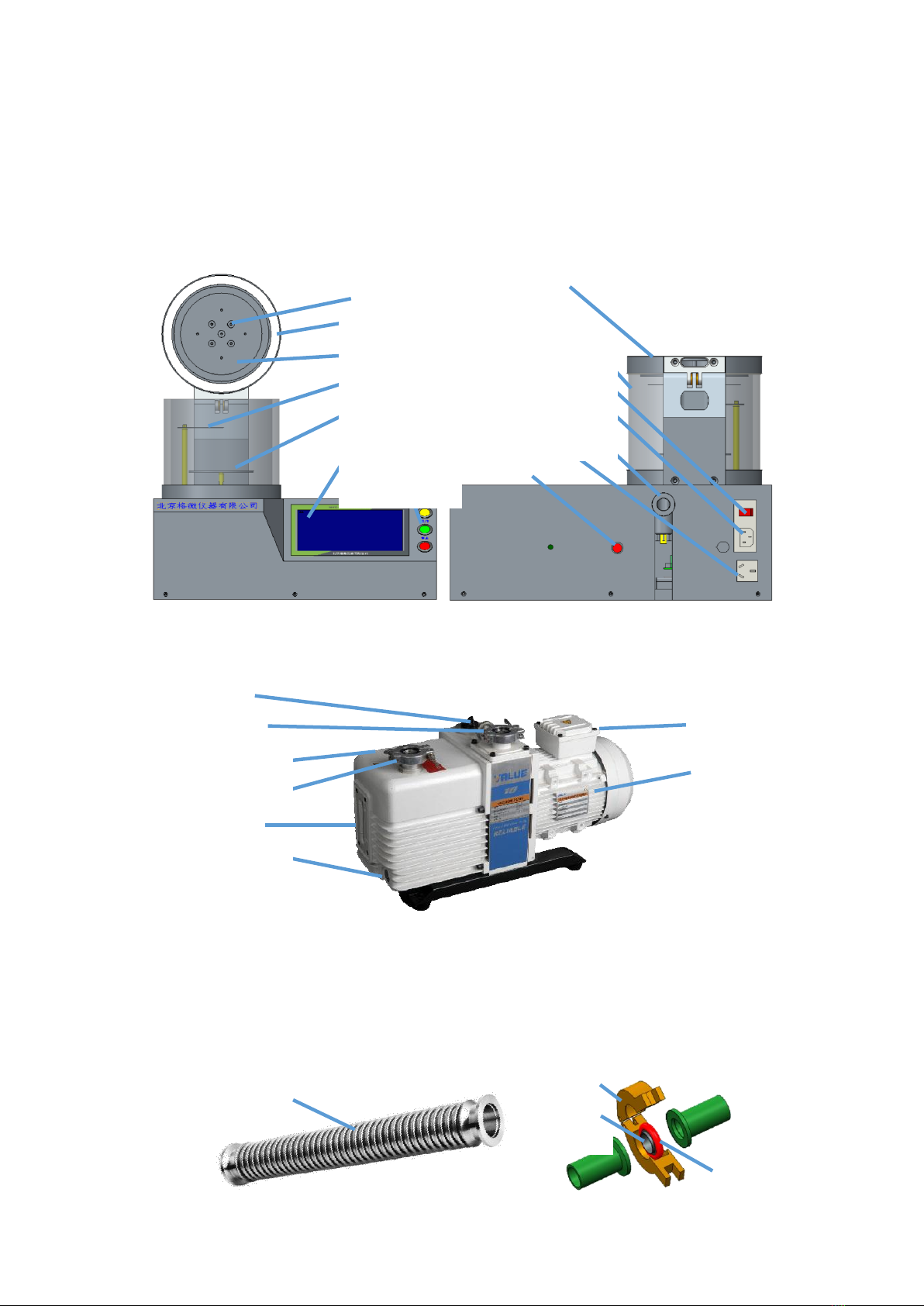

3.2 Appearance and Composition of Vacuum Pump.................................................................3

3.3 Connecting Pipe Line..........................................................................................................3

3.4 Brief Introduction of Functions...........................................................................................4

3.4.1 Mainframe........................................................................................................................4

3.4.2 Function of Vacuum Pump...............................................................................................4

3.4.3 Connecting Pipe Line.......................................................................................................4

VI. Software Interface.......................................................................................................................4

4.1 Main Interface (Taking Pulse Heating Mode as An Example)............................................4

4.1.1Parameter Settings.............................................................................................................5

4.1.2 Information Hint...............................................................................................................5

4.1.3 Working Status -- Real-Time Curve.................................................................................5

4.1.4 System Status ...................................................................................................................5

4.2 System Setting Interface .....................................................................................................6

4.3 Advanced Setting ................................................................................................................8

V. Installation and Operation.............................................................................................................9

5.1 Equipment Installation ........................................................................................................9

5.1.1 Preparatory Work .............................................................................................................9

5.1.2 Pipeline Connection .......................................................................................................10

5.1.3 Circuit Connection .........................................................................................................11

5.1.4 Check .............................................................................................................................11