Table of contents" #....................................................................................................................................2

1. Safety requirements" #...........................................................................................................................4

2. Operation principle" #.............................................................................................................................5

2.1.Features and advantages!..............................................................................................................................................5

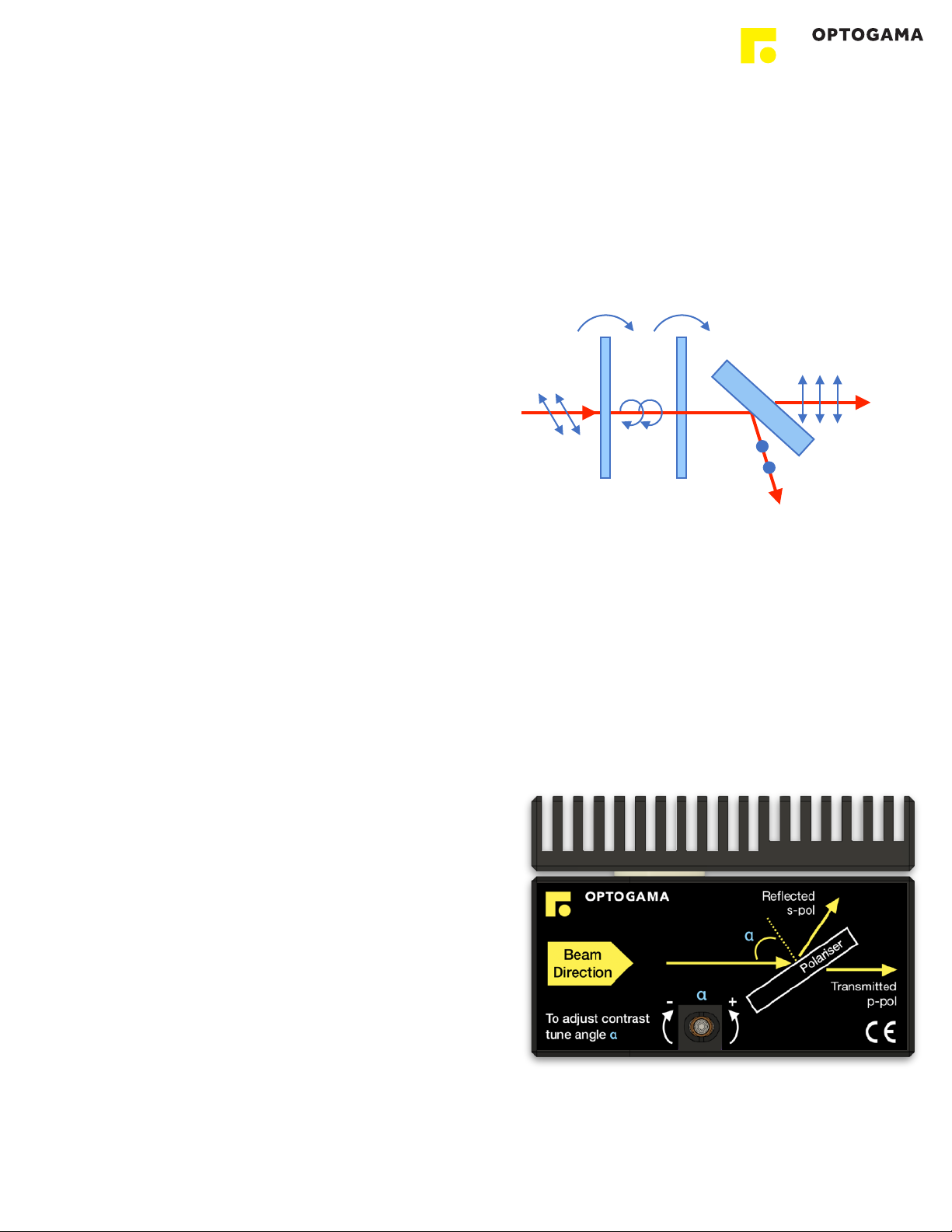

2.2.Optical design!...............................................................................................................................................................5

2.3.Contrast improvement. Angle adjustment!.....................................................................................................................5

3. Product description" #............................................................................................................................6

3.1.Optical specifications!....................................................................................................................................................6

3.2.Mechanical specifications!.............................................................................................................................................6

3.3.Electronic specifications!................................................................................................................................................6

3.4.Conditions!....................................................................................................................................................................6

4. Measurements" #....................................................................................................................................7

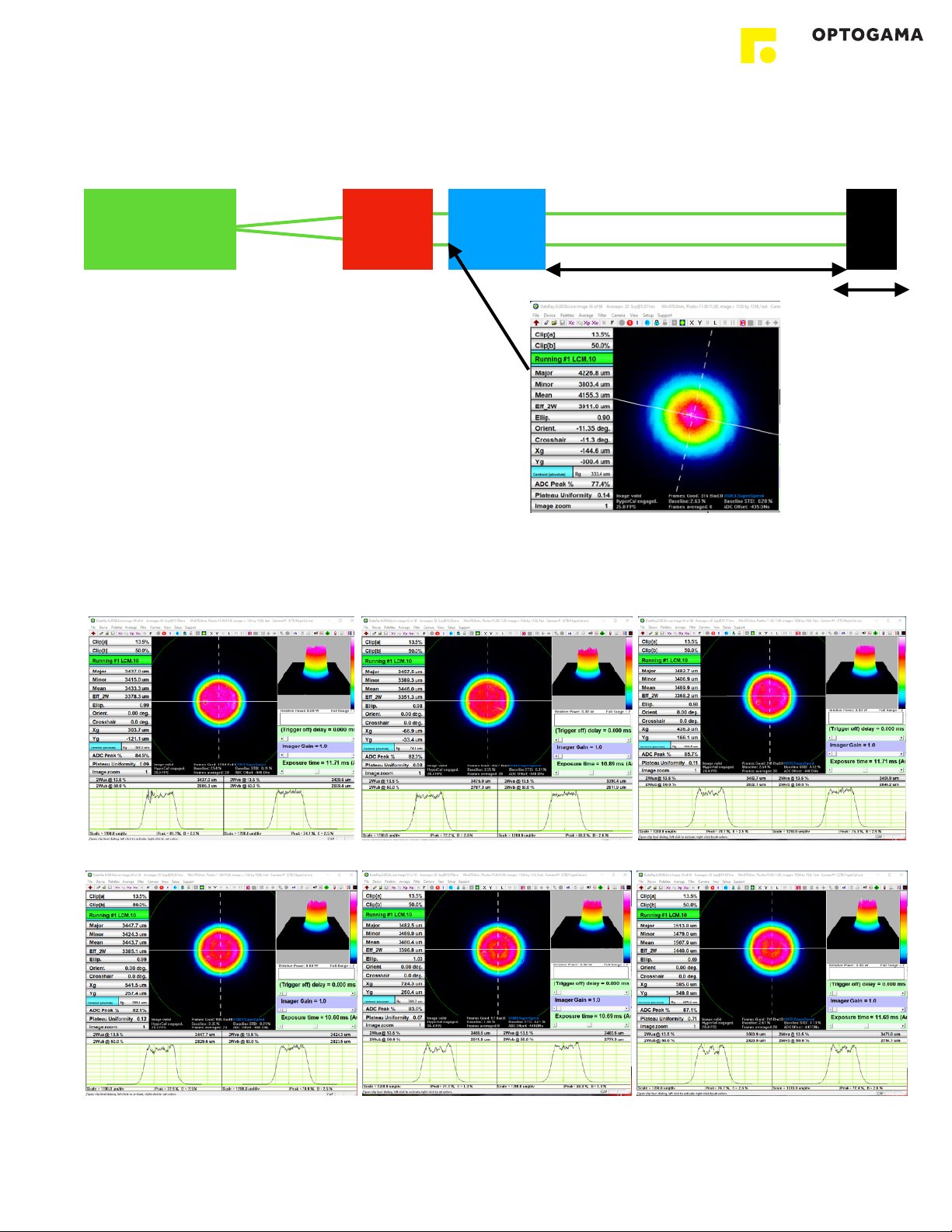

4.1.Setup parameters!.........................................................................................................................................................7

4.2.Flat top mode (no expander after FTC)!..........................................................................................................................7

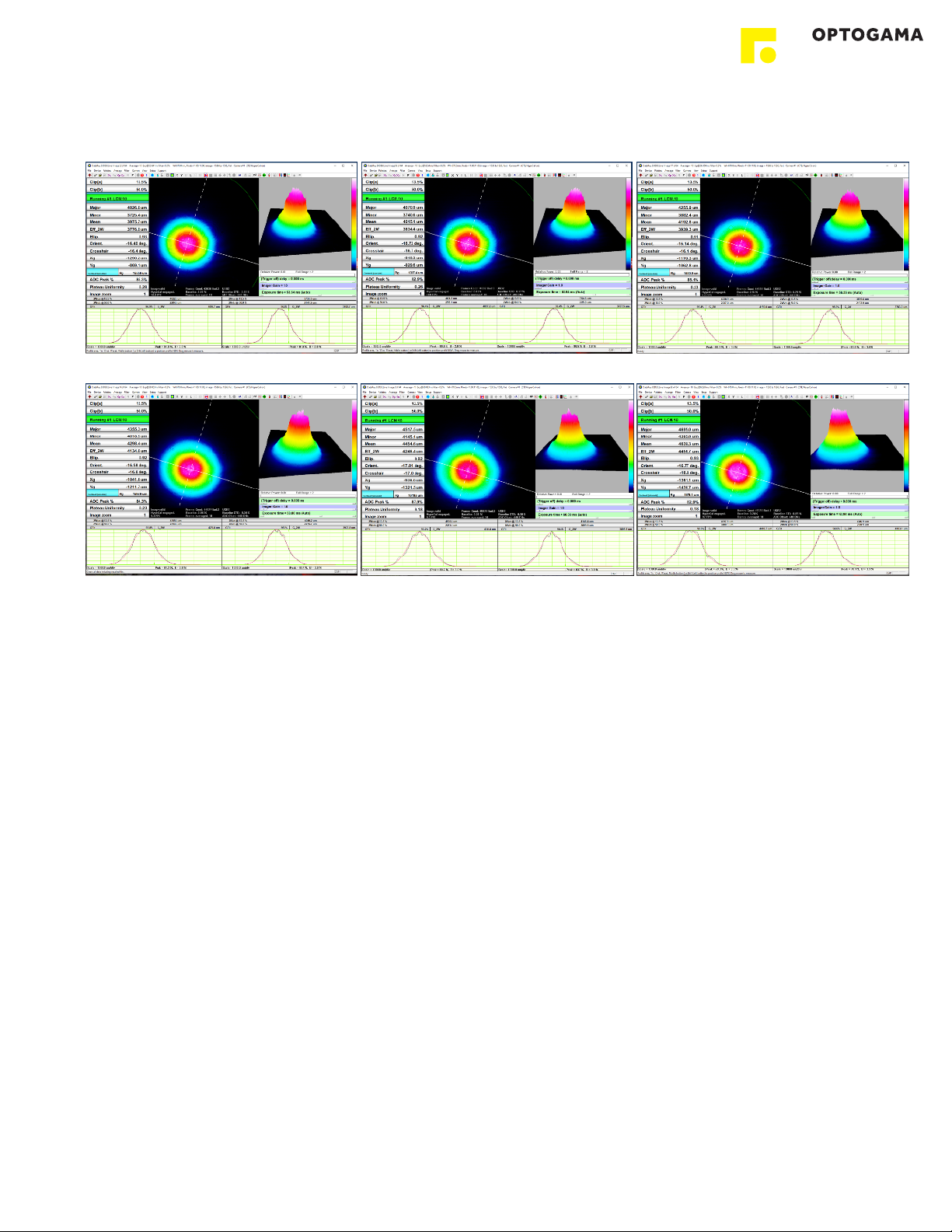

4.3.Gaussian beam mode!...................................................................................................................................................8

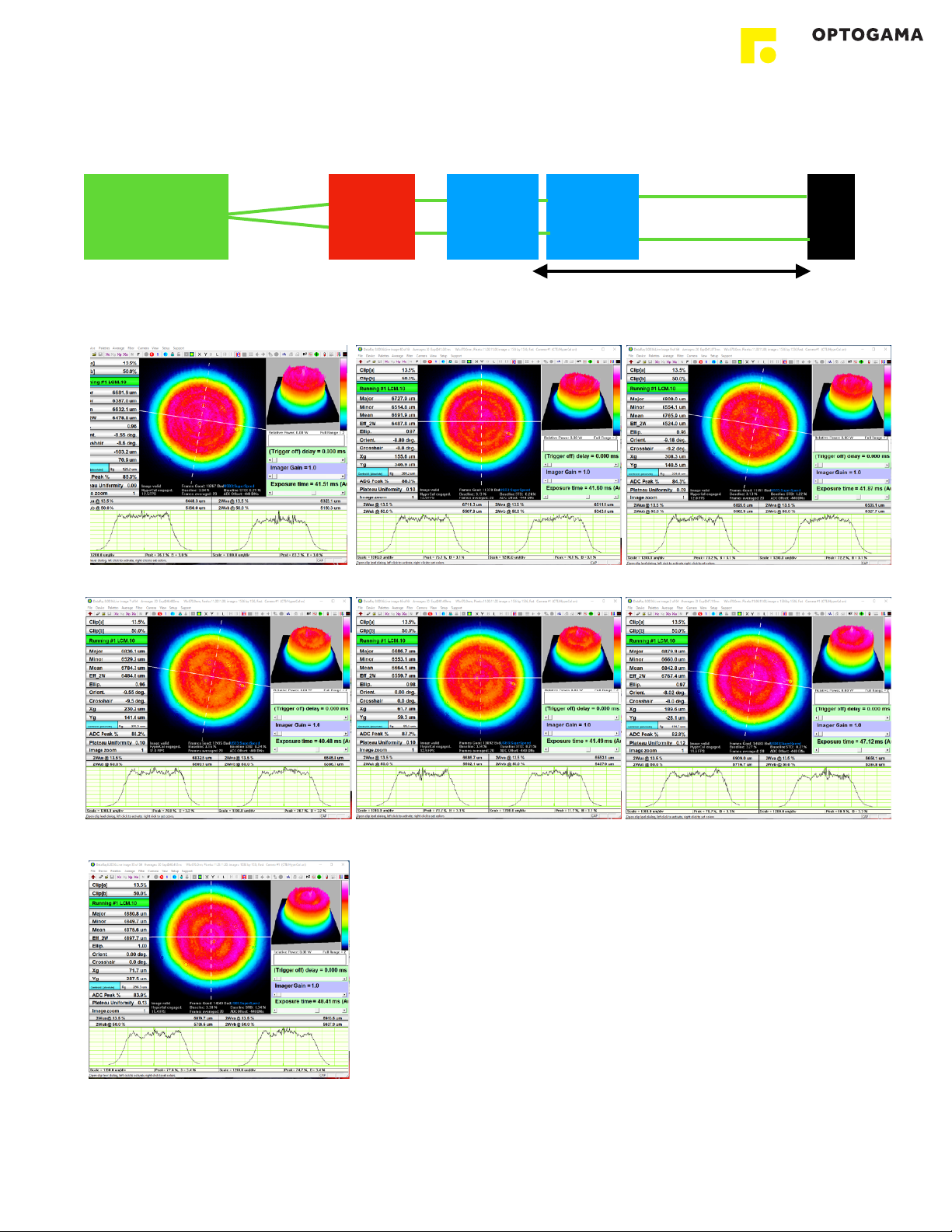

4.4.FTC with beam expander (2X)!.......................................................................................................................................9

4.5.FTC with beam expander (3X)!.....................................................................................................................................10

4.6.Focusing Flat Top beam (with 3X expander)!................................................................................................................11

5. Controller" #..........................................................................................................................................12

5.1.Interfaces, pinout!........................................................................................................................................................12

5.2.Voltage levels!..............................................................................................................................................................12

5.3.What’s in the box?!......................................................................................................................................................12

5.4.Available accessories!..................................................................................................................................................12

6. Software" #...........................................................................................................................................13

6.1.Minimum Hardware requirements (recommended)!......................................................................................................13

6.2.System requirements!..................................................................................................................................................13

6.3.Supported client operating systems!............................................................................................................................13

6.4.Installing the software!.................................................................................................................................................13

6.5.Using the software!......................................................................................................................................................15

6.5.1.Connection!............................................................................................................................................................15

6.5.2.Settings, calibration!................................................................................................................................................15

6.5.3.Main window!..........................................................................................................................................................16

6.6.Updating the firmware!................................................................................................................................................17

4. Commands" #......................................................................................................................................18

4.1.Interface!.....................................................................................................................................................................18

4.2.Description!.................................................................................................................................................................18

5. Troubleshooting" #................................................................................................................................21

5.1.STATUS bits explanation!.............................................................................................................................................21

5.2.Serial communication example in Python!....................................................................................................................22

6. Technical information" #.......................................................................................................................23

6.1.FTC drawings!.............................................................................................................................................................23

6.2.Power supply!..............................................................................................................................................................24