USER MANUAL OM PROFI | 9

.

DESCRIPTION

OF COMMUNICATION

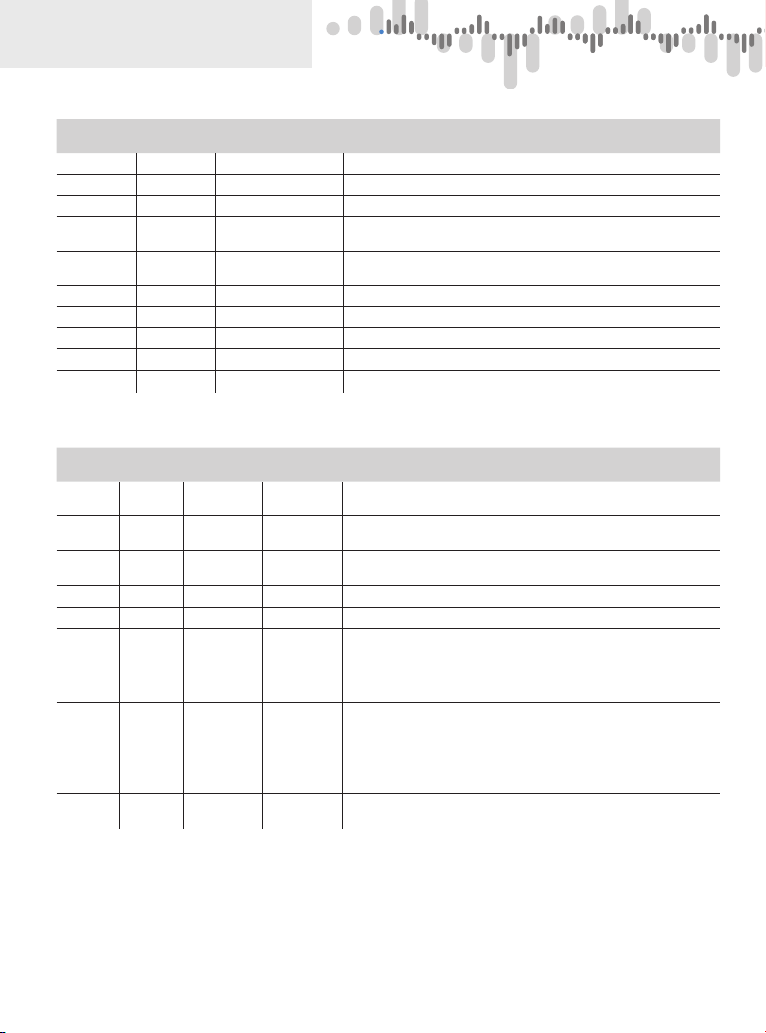

OM Profibus card parameters stored inEEPROM (older version or selection of GSD file in menu - OLD)

Addr. Record

value

Function Manufact.

value

Note

3 131 TimeOut -

OM xxx

4

197…260 ms

Delay for reporting errors in communication with OM xxx instruments

X * 66 ms (inaccuracy from X – 1 to X)

4132 TimeOut -

Profibus

76

aprox. 5 s

Delay for reporting errors in communication to ProfiBus

X * 66 ms (inaccuracy from X – 1 to X)

5133 Transmiss.

delay

8

aprox. 0,6 s

Delay used for downloading in cycles or display projection

(66…131 ms) + X * 66 ms

6 134 Unused (Only for OMX ProfiBus)

7 135 Unused (Only for OMX ProfiBus)

10…29 138…147 Reserve May be used to record values

(Max. 100 000 records (100k Write Cycles))

List of modes („Functions“)

„Function“ Function Note

0 Downloading

values fromOM

xxx instruments

Channel values are downloaded in cycles from theOM xxx instrument with set Address.

Betweendownloadingsthereis a delayinserted,which is setin„Transmission delay“inEEPROM

of the OM Profibus card.

10…15 Displaying

numbersonOM

xxx instrument

Setting display onto decimal number value is repeated in cycles

(function 10 = w/o d.p., 5 = 5 decimal places)

Afterfunction termination (interrupted communication, change of address) the numberstops

displaying itself after approx. 2,5 s

20 Inserting and

projectingdeci-

mal number in

OM xxx instru-

ment

Functions are designed for OM xxxRS instruments, which are able to receive and

process the value (re-calculate, evaluate limit statuses, set the analog output, dis-

play the value in relevant format, change the display colour as per value size).

The value stays projected in the instrument until another value is recorded or the instrument

switches off.

30 Inserting and

projecting inte-

ger number in

OM xxx instru-

ment

Functions are designed for OM xxxRS instruments, which are able to receive and

process the value (re-calculate, evaluate limit statuses, set the analog output, dis-

play the value in relevant format, change the display colour as per value size).

The value stays projected in the instrument until another value is recorded or the instrument

switches off.

100 Projection of

text on display Projection of text on OM xxx instrument display is repeated in cycles.

128 Projection of

OMxxx instrum.

identification

Projection of current OM xxx instrument identification ascertained after the Profibus card

is switched on.

129…130

229…230 Sending

OM command

Upon the change of function OM command is sent to RS 485 line. Functions 129 and130

are waiting for response from OM xxx instrument. Received answer is stored in transmitted

telegramu.

131 Bulk parameter

downloading

The telegram area designed for data is completed with the EEPROM content of OM Profibus

card, in which the card‘s parameters are stored

132 Downloading

SW version

Thetelegramareadesigned fordatais completedwithSWidentificationof the OM Profibuscard

e.g.: „V.1.1.2 - 11/16/07 16:47:20(B737)“, the brackets give a check sum of the card‘s program

memory

133 EEPROM

check sum

The telegram area designed for data is completedwith a check sum of the EEPROM memory

in which the OM Profibus card parameters are stored. E.g..: „1327“

134 Downloading

counters

The telegram area designed for data is completed with service counters readings

(card‘s number of switch-on cycles and total running time) E.g.: „000012;000006“

No data is downloaded unless the „Flag“ value is set to and the „Function“ and„Address“ values are not identical in both telegrams (the received and

the transmitted).

Similar rule applies to an executed command: unless the „Function“ and „Address“ values are not identical in both telegrams (the received and the

transmitted), the function is not performed