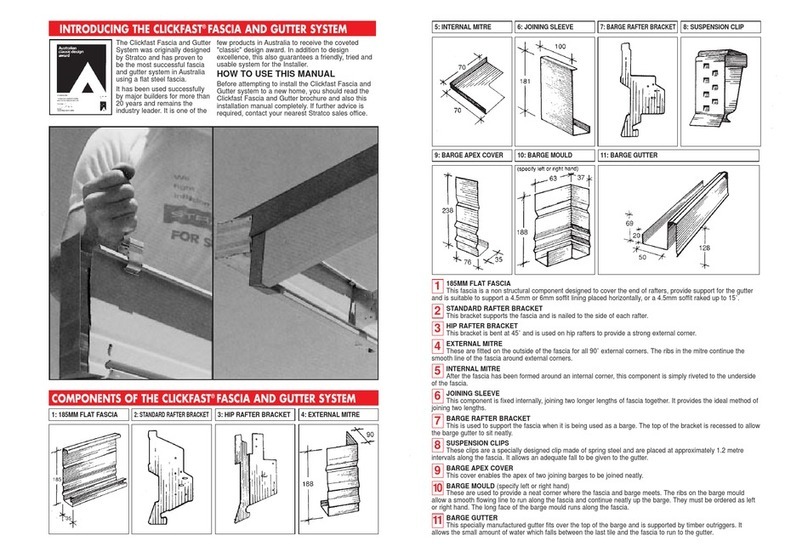

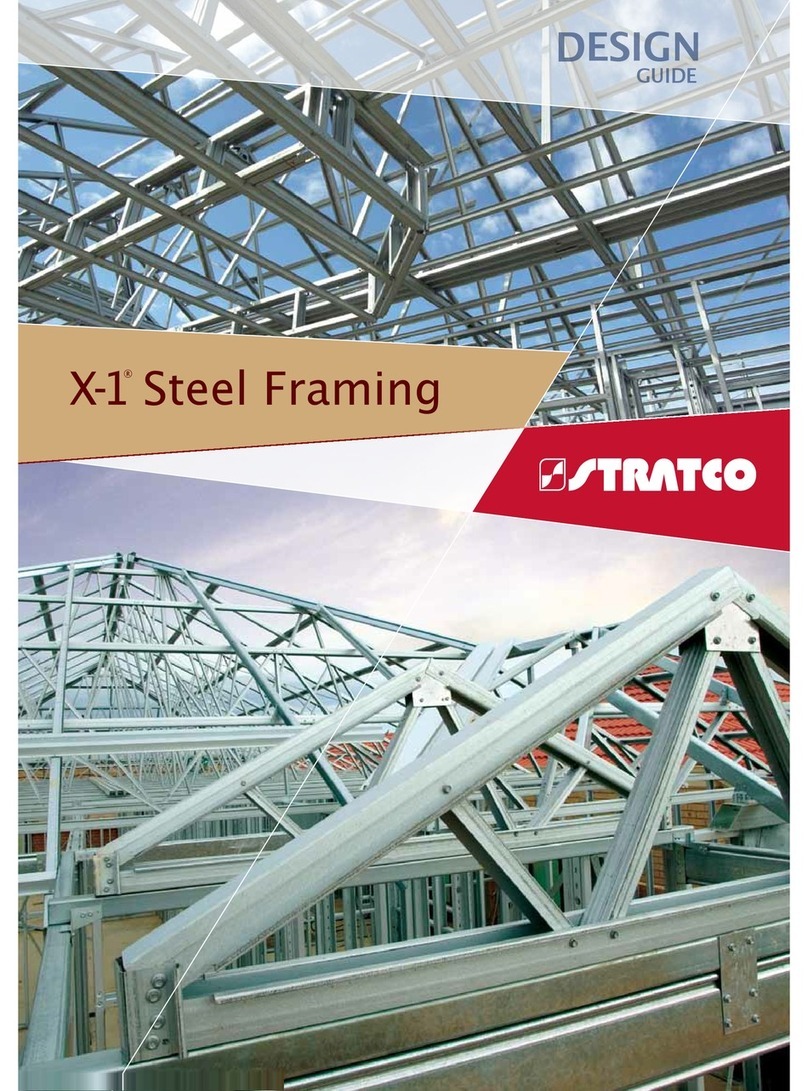

CLIP SPACING

Knock suspension clip

down with fist. Place at 1.2

metre

intervals.

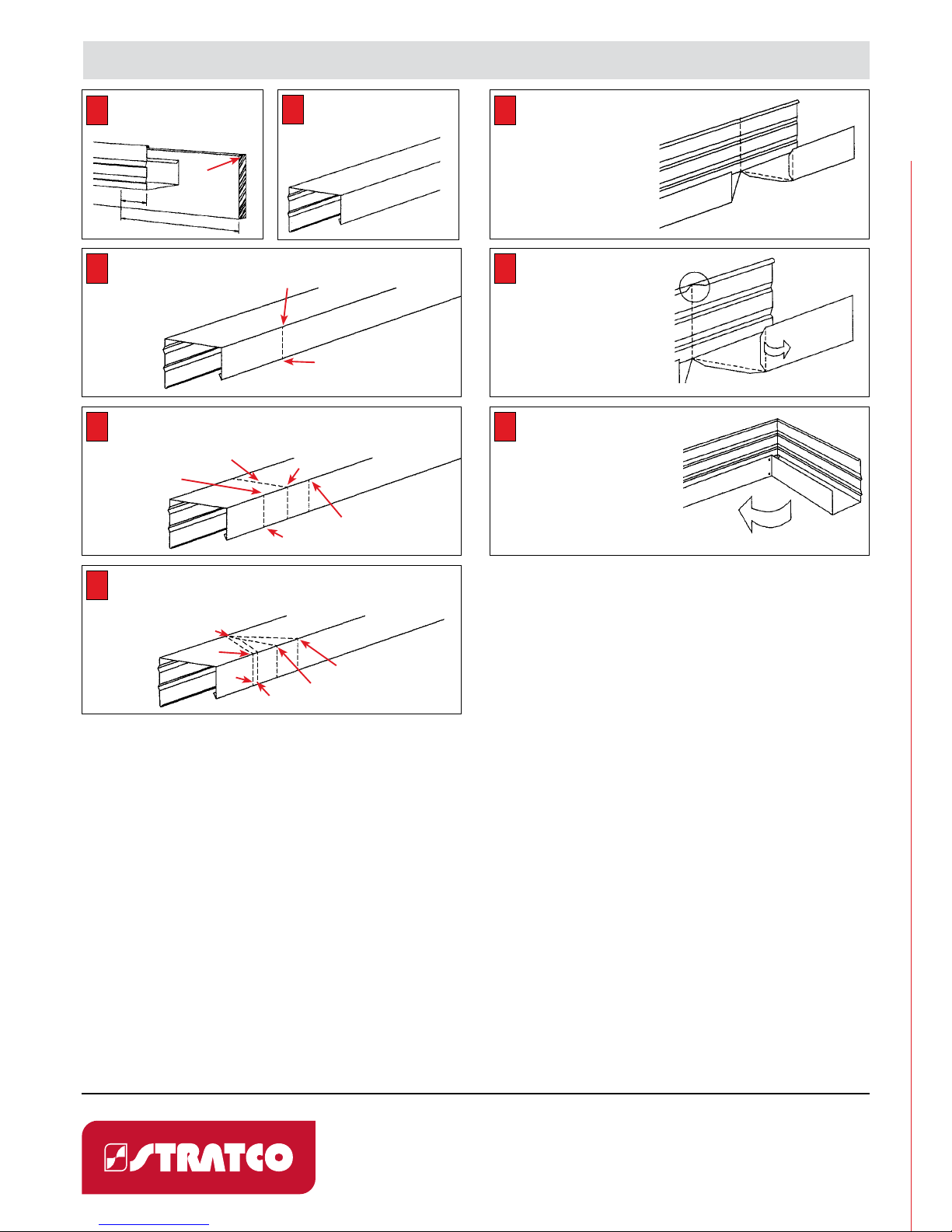

1: Measure the distance between the bottom

of the gutter to the ground level (leave

enough to fit a shoe or PVC fitting).

2: Slide the small end of one downpipe

(marked by a cut V or dot one end) into the

big end of the other. Rivet the downpipe at

the back as not to show the rivet head, then

use a hacksaw to cut to the desired length.

3: Fit the downpipe to the existing outlet

using rivets, then using downpipe straps,

fix against wall or post using screws or

masonry nails.

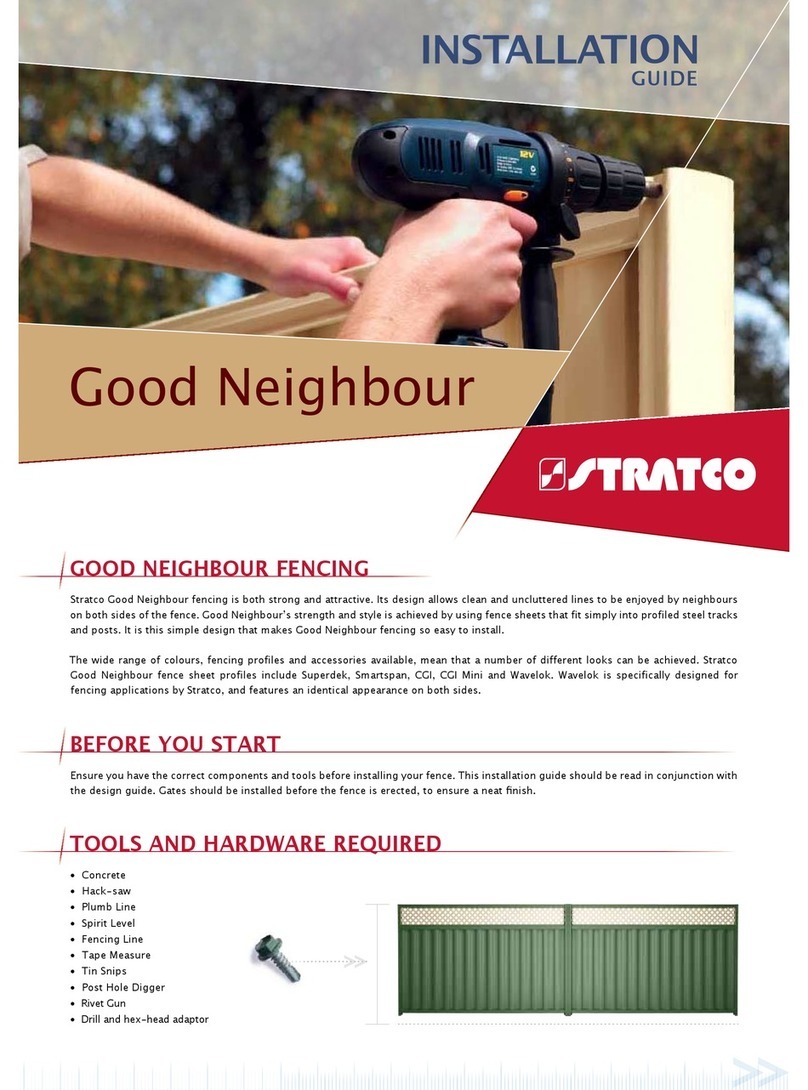

1: Determine if the end is to be left or right.

2: Mark a line completely around the outside

of the gutter at a distance from the end,

equal to the width of the gutter.

3: Mark a tag-line paralell to the first

approximately 10mm toward the end of

the gutter, across the back and the base of

the gutter.

4: Cut the back and the base from the gutter

leaving the 10mm tags in place. Fold these

up at 90 degrees.

5: Cut a 45˚notch in the bead of the gutter

at the marked line, and fold the face of the

gutter to form the end.

6: Rivet and silicone.

FIXING DOWNPIPE TO GUTTER

MAKING ‘RETURN’ STOP ENDS

When installing downpipes, sometimes

the eaves overhang will require the use of

a downpipe offset. There are two ways of

producing a downpipe offset.

1: Stratco produce a complete downpipe

offset, which is suitable for your

nominated eaves dimension. This has a

slip joint to make it adjustable for small

variances in eaves sizes, which may vary

on your home.

2: Elbows and shoes can also be pre-made

and then riveted onto your downpipe

length producing your own downpipe

offset. Alternately, one piece downpipe

offsets can be made on the site.

DOWNPIPE OFFSETS

INSTALLATION OF GUTTERS

USING SUSPENSION CLIPS

Gutter is pulled upwards until the suspension clip engages into the

suspension rib of gutter. Place internal gutter strap into position.

The fall of the gutter is obtained by a series of teeth placed on the

suspension clip. The highest end of the gutter should be in the top

tooth. The lowest end in the second to bottom (minimum 1: 500

fall required).

ROLL IN CLIPS.

Push suspension clip up

from rear and into the

vertical

position as

shown.

12

INSTALL GUTTER

Pull gutter upwards until

suspension clip engages.

3FIX INTERNAL STRAPS

Roll gutter strap into bead

& press over top of fascia.

4

Using a hacksaw, cut

a small section out

inside the lines, big

enough to gain access

for your tinsnips.

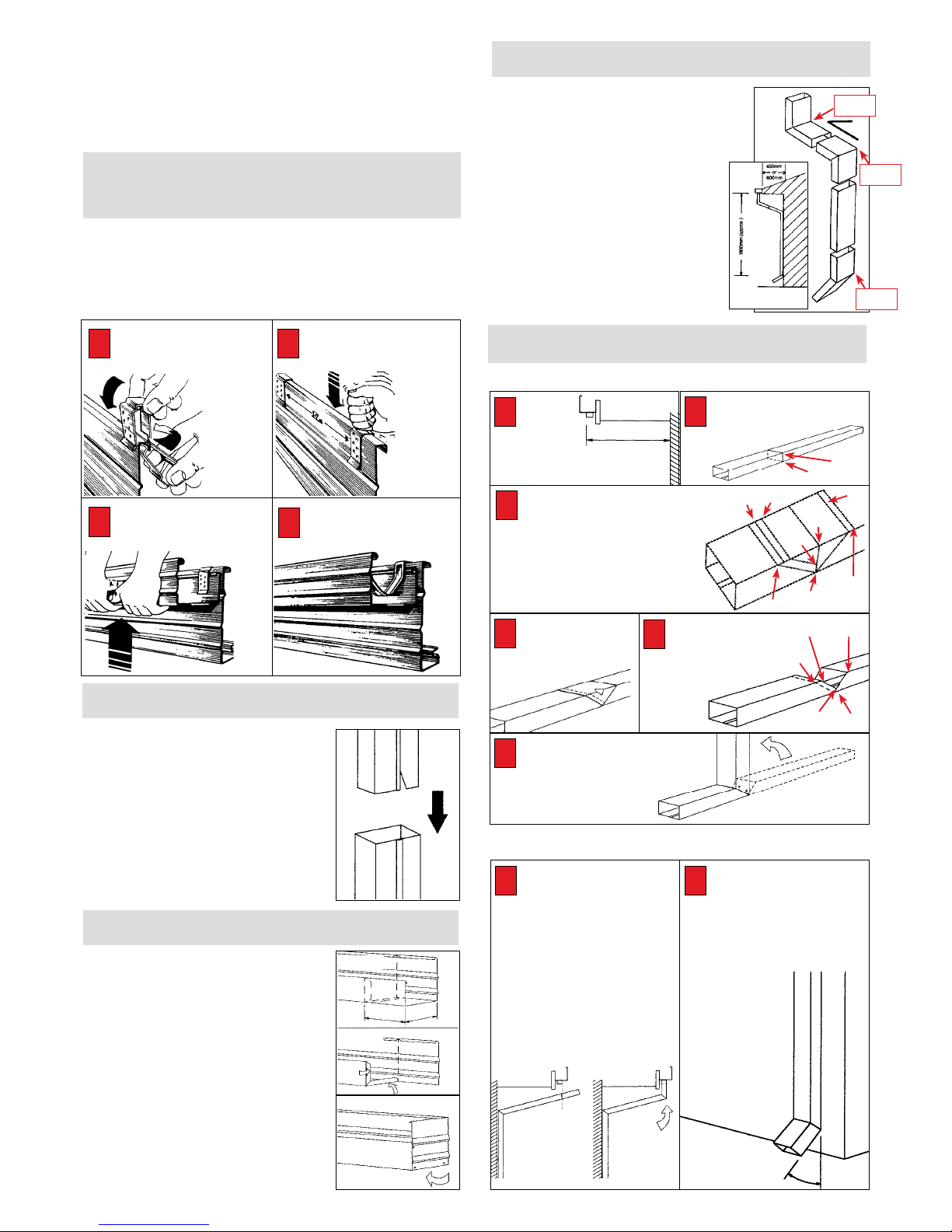

Steps 1-3

Steps 4-5

Small

end

Large

end

Steps 5-6

4

Using snips, cut along

the “inside” lines of

C1-A1-A2-B2 leaving the

10mm tag for the lap

joint intact. Complete the cut

across the face of the

downpipe and

repeat on the

other side.

5

Bend the downpipe along the undercut

side to allow the big end of the

downpipe to fit inside the lower part

of the offset.

Rivet and silicone.

6

Place completed “Lower Offset”

joint against the wall with the

large end of downpipe towards the

gutter outlet.

• Using a plumb line mark from the

outside of the gutter outlet, completly

down the side of downpipe. This point

becomes the centre point of the cut of

the upper offset joint, to be marked

out. Cut and seal as per steps 3 to 6

above. It is important to note that for the

“Upper Offset” the opposite face of the

downpipe is used so the seam is cut.

• Before riveting the top of the offset

joint completely, check to make sure the

top of the offset joint is parallel to the

bottom part of the downpipe offset.

1

GUTTER INSTALLATION CONTINUED

5: Fit pre-made gutter mitres as required.

6: Roll internal straps into the bead of the gutter if being used and

fasten to the top of the fascia. Use the gutter strap to ensure the

bead remains parallel to the fascia.

7: Fit downpipe, downpipe accessories and straps.

CREATING THE “LOWER OFFSET” JOINT.

CREATING THE “UPPER

OFFSET” JOINT

Using a second length of down-

pipe, measure in from the “small”

end of the downpipe, the length

required to bring the downpipe

into the stormwater pipe, allowing for a

slip joint, and mark this distance com-

pletely around the pipe using a square.

• To create a 45 degree angle, mark a

distance equal to half the width of

the downpipe on

either side of this cen-

tre line on the face of

the downpipe.

• Mark out, cut and

seal as per steps

3 - 6 above.

• Slide the upper and

lower offsets together

to form the final

finished offset.

1

CREATING THE “SHOE”

Place this measurement along the

downpipe starting from the “Big End”,

and mark this completely

around the pipe at point.

A.

45˚

Measure

from the wall

to the outside

of the gutter outlet.

Add to this measurement 100mm plus

twice the width of the downpipe.

1

Measure the width of the downpipe.

Mark this width on the face of the

downpipe either side of the centre line

to points Band C. To achieve an angle

of approx. 100˚(which allows for downpipe

fall) come in 10mm both sides to B1 and C1.

On the big end side of the centre line come in

a further 10mm for a lap to point B2.

Join points B-A1, C1-A1, and draw a line

parallell to B-A1 to intersect A-A1 at A2.

3

A1

B1

B1

B2

B2

A

A

C1

C1

B

A1

A1

C

A2

A2

100˚

STRATCO PRE-

MADE OFFSET

Lower off-

set joint

Upper off-

set joint

Downpipe

shoe

2

MAKING A DOWNPIPE OFFSET