BTP-M170 User’s Manual

- 3 -

Contents

GENERAL SAFETY INSTRUCTION ....................................................................................... 1

1 OVERVIEW......................................................................................................................... 2

1.1 OUTLINE ...................................................................................................................... 2

1.2 FEATURES ................................................................................................................... 2

1.3 MODEL CLASSIFICATION............................................................................................. 2

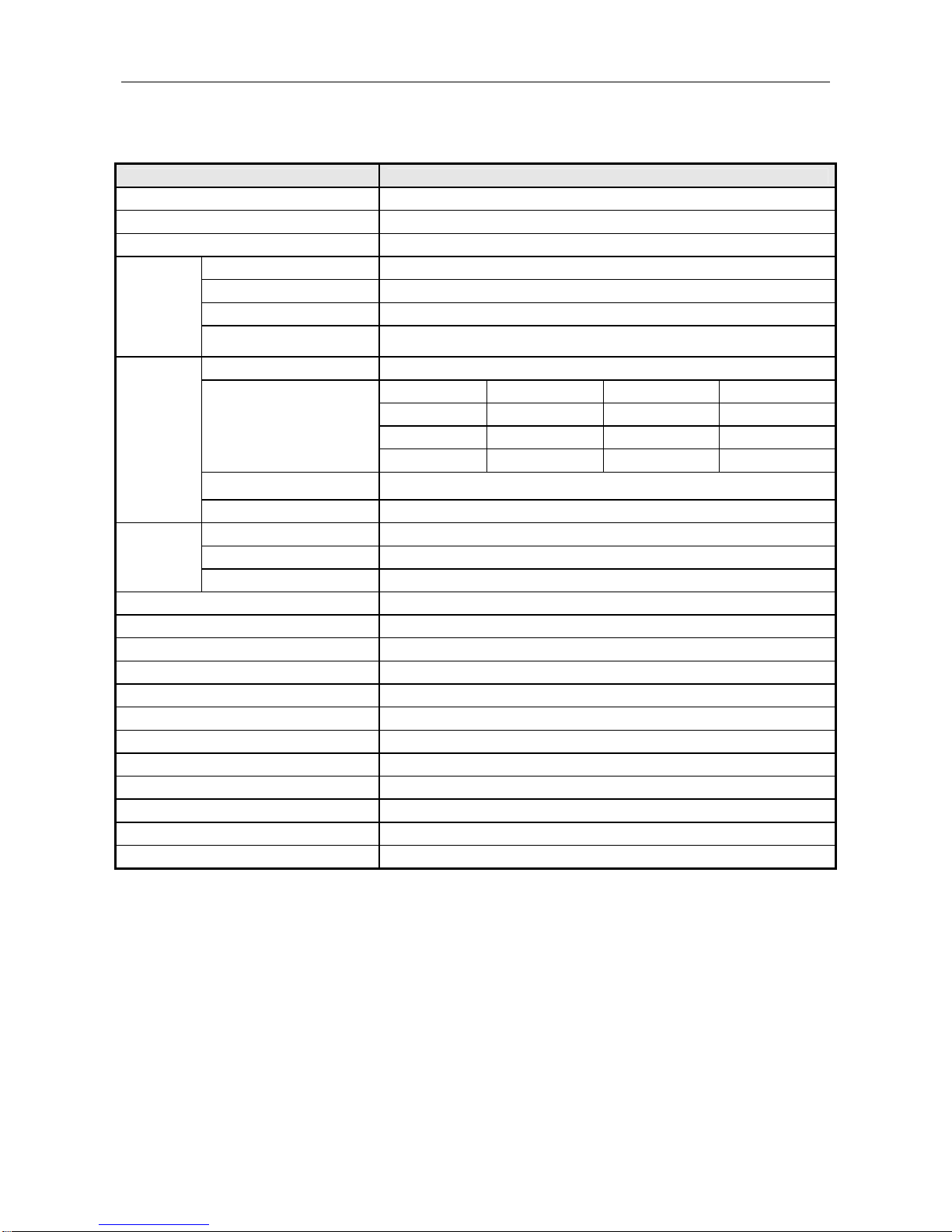

2 SPECIFICATIONS............................................................................................................... 3

2.1 MAIN SPECIFICATION .................................................................................................. 3

2.2 PAPER SPECIFICATION ............................................................................................... 4

2.2.1 Continuous paper .................................................................................................... 4

2.2.2 Marked paper.......................................................................................................... 4

2.2.3 Recommended paper .............................................................................................. 4

2.3 PRINT AND TEAR-OFF POSITION ................................................................................ 5

2.3.1 Print position........................................................................................................... 5

2.3.2 Tear-off position ...................................................................................................... 5

3 OUTLINE AND PARTS........................................................................................................ 6

3.1 OUTLINE AND PARTS .................................................................................................. 6

3.2 LEDS AND BUZZER ...................................................................................................... 7

4 INSTALLING ....................................................................................................................... 8

4.1 UNPACKING ................................................................................................................. 8

4.2 INSTALLING POSITION AND DIRECTION OF THE PRINTER........................................ 8

4.3 CONNECTING THE POWER ADAPTER ........................................................................ 8

4.4 CONNECTING SIGNAL CABLE ..................................................................................... 9

4.5 CONNECTING THE CASH DRAWER............................................................................. 9

4.6 LOADING THE ROLL PAPER ...................................................................................... 10

4.6.1 Confirming the media ............................................................................................ 10

4.6.2 Loading/replacing roll paper .................................................................................. 10

4.7 LOADING RIBBON .......................................................................................................11

4.8 SELF-TEST ..................................................................................................................11

4.9 INSTALLING THE PRINTER DRIVER .......................................................................... 12